Hybrid excitation synchronous generator with low cogging effect

A synchronous generator and compound excitation technology, applied in synchronous motors with static armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of large starting resistance, excitation generators , the number of turns of the excitation winding is small, etc., to achieve the effect of reducing the starting resistance and operating noise, increasing the main magnetic flux, and improving the integral torque coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

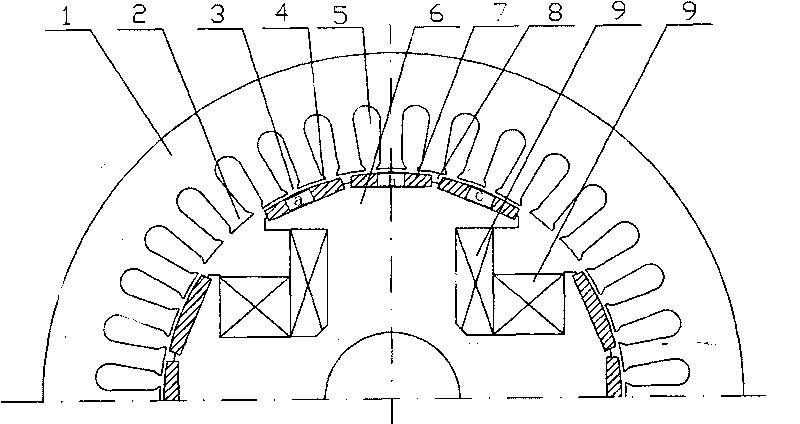

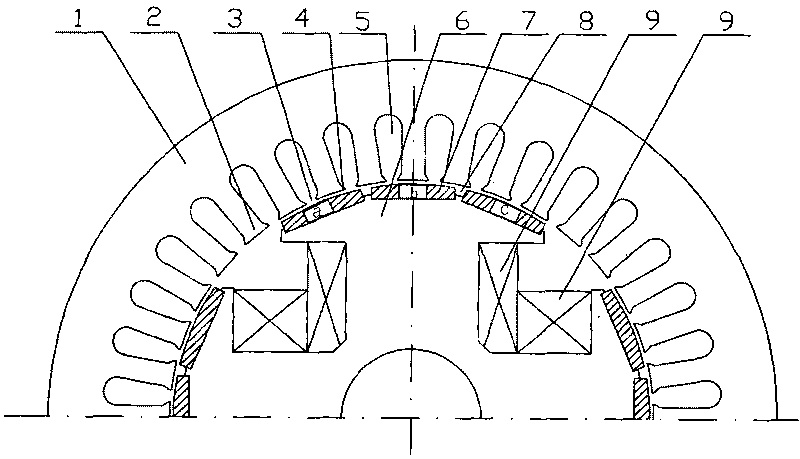

[0007] Specific implementation mode one: combine figure 1 The present embodiment will be described. This embodiment is composed of stator core 1, stator teeth 2, stator tooth yoke 4, rotor pole yoke 6, permanent magnet 7, non-magnetic space 8 and rotor winding 9, slot 5 is opened on stator core 1, and stator Teeth 2 are set in the middle of two adjacent slots 5, and a plurality of permanent magnets 7 of different or different sizes are arranged on the surface of the rotor pole yoke 6. The permanent magnets 7 are made of neodymium iron boron magnetic material, and the permanent magnets 7 The polarities of the permanent magnets are the same, and a non-magnetically permeable space 8 is provided between two adjacent permanent magnets 7, and the distance between the permanent magnets 7 keeps a certain ratio.

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 The present embodiment will be described. The thickness of the permanent magnet in this embodiment can make the magnetic saturation value of the permanent magnet reach 70%-85%.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 The present embodiment will be described. In this embodiment, the sizes of the permanent magnets 7 and the stator teeth 2 are scaled up or down according to the size of the inner diameter of the stator, but the numbers of the permanent magnets 7 and the stator teeth 2 remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com