Processing webs of wrapping material

A material belt and processing industry technology, applied in the field of coiled material belt processing, can solve problems such as impact and production speed reduction, and achieve the effects of reducing solidification time, improving adhesion, and improving production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following figures, the same or identical elements or corresponding parts are each marked with the same reference numerals, so that no corresponding reintroduction is necessary.

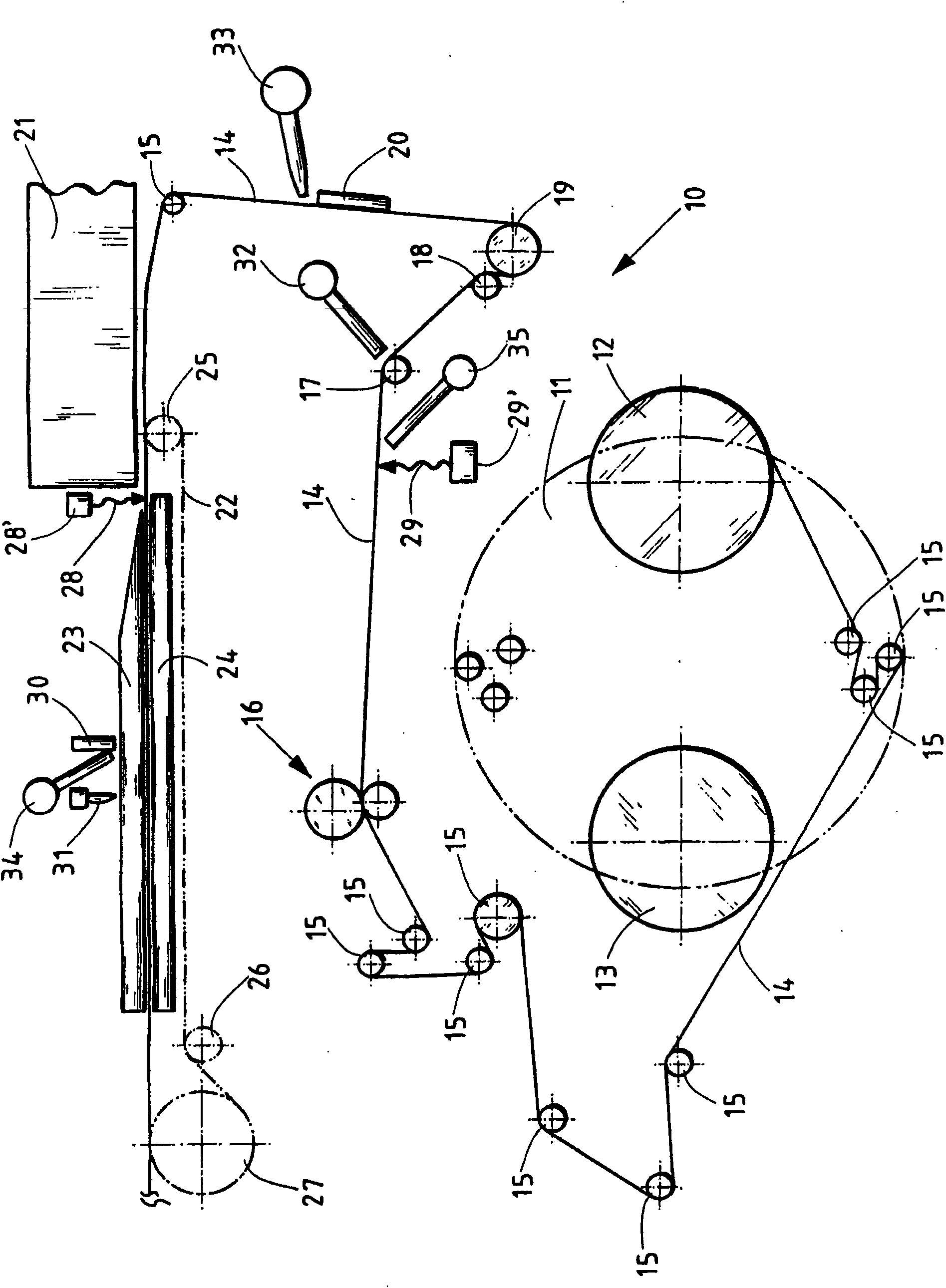

[0023] figure 1 A portion of a tobacco rolling machine 10 is shown, such as a cigarette rolling machine or a filter rolling machine.

[0024] Two bobbins 12 and 13 are mounted on a bobbin changer 11 . Typically a web of rolled material 14 is drawn from bobbin 12 . The web of rolled material runs over various guide rollers 15 . A traction pair 16 is provided, which correspondingly draws the coiled material strip 14 . Simultaneously, the bobbin 12 is also driven by an electric motor, so that no excessive tensile stresses are produced on the wrapping material web 14 or on the cigarette paper 14 . The web of wrapping material or cigarette paper 14 has regions which have a reduced oxygen permeability compared to other cigarette papers. This area can be produced by the application of addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com