Preparation method of anti-oxidation fish protein edible film

A fish protein and antioxidant technology, applied in packaging, wrapping paper, flexible coverings, etc., can solve problems such as restricting the development of freshwater fishery production, and achieve the goal of improving UV blocking performance, increasing added value, and improving mechanical strength and transparency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

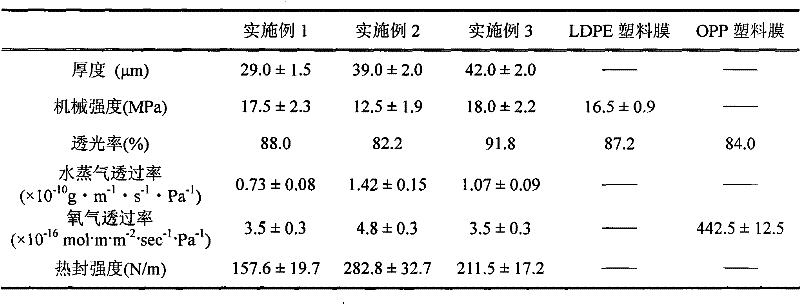

Embodiment 1

[0030] 1. Dissolution of protein: mince silver carp, then dissolve 14g of minced silver carp fish pulp in 100ml of ice-cold distilled water, adjust the pH of the fish meat aqueous solution to 3.0 with hydrochloric acid, heat it at 70°C for 30 minutes Cool quickly with ice water to below 10°C.

[0031] 2. Centrifugation: The heated and cooled fish protein solution is centrifuged (5000×g, 4° C., 30 min) to remove insoluble substances.

[0032] 3. Preparation of membrane liquid: adjust the protein concentration in the fish supernatant obtained by centrifugation to 2.0%, then add 0.2% glycerin and 0.1% BHT, stir evenly and use a defoamer to defoam, and prepare edible fish protein Membrane liquid.

[0033] 4. Preparation of protein film: Pour 4g of the prepared film solution into a 5cm×5cm silicone resin frame (1.6kg / m 2 ), dried in a constant temperature and humidity chamber at 25°C and a relative humidity of 50% for 24 hours, and then peeled off from the silicone resin to obtai...

Embodiment 2

[0036] 1. Dissolution of protein: Mince the carp, then dissolve 20g of minced carp pulp in 100ml of ice-cold distilled water, adjust the pH of the fish solution to 3.5 with citric acid, heat it at 100°C for 10 minutes, and quickly Cool to below 10°C with ice water.

[0037] 2, centrifugal: centrifugal method is identical with example 1.

[0038] 3. Preparation of membrane liquid: adjust the protein concentration in the fish supernatant obtained by centrifugation to 3.0%, then add 1.0% glycerin fatty acid ester and 0.5% rosemary, stir evenly, and use a defoamer to defoam to prepare Edible membrane fluid of fish meat protein.

[0039] 4. Preparation of protein film: Pour 3.5g of the prepared film solution into a 5cm×5cm silicone resin frame (1.4kg / m 2 ), dried in a constant temperature and humidity chamber at 25°C and a relative humidity of 50% for 18 hours, and then peeled off from the silicone resin to obtain a transparent fish protein edible film. The thickness, mechanical...

Embodiment 3

[0041]1. Protein dissolution: Mince grass carp, then dissolve 17g of minced grass carp pulp in 100ml of ice-cold distilled water, adjust the pH of the fish solution to 4.0 with acetic acid, heat it at 80°C for 20 minutes, and then use it quickly Cool in ice water to below 10°C.

[0042] 2, centrifugation: centrifugation method is identical with example 1.

[0043] 3. Preparation of membrane liquid: adjust the protein concentration in the fish supernatant obtained by centrifugation to 2.5%, then add 0.5% sorbitol and 0.3% vitamin C, stir evenly, and use a defoamer to defoam, and prepare fish Protein edible film membrane fluid.

[0044] 4. Preparation of protein film: Pour 4.5g of prepared film solution into a 5cm×5cm silicone resin frame (1.8kg / m 2 ), dried in a constant temperature and humidity chamber at 25°C and a relative humidity of 50% for 36 hours, and then peeled off from the silicone resin to obtain a transparent fish protein edible film. The thickness, mechanical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com