Meta-synthesis construction method of 600MW unit bag-type dust remover

A bag filter, a comprehensive and integrated technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of inability to construct, cannot cover the construction area, and increase the difficulty of construction, so as to reduce construction costs and improve labor. Efficiency, the effect of improving dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

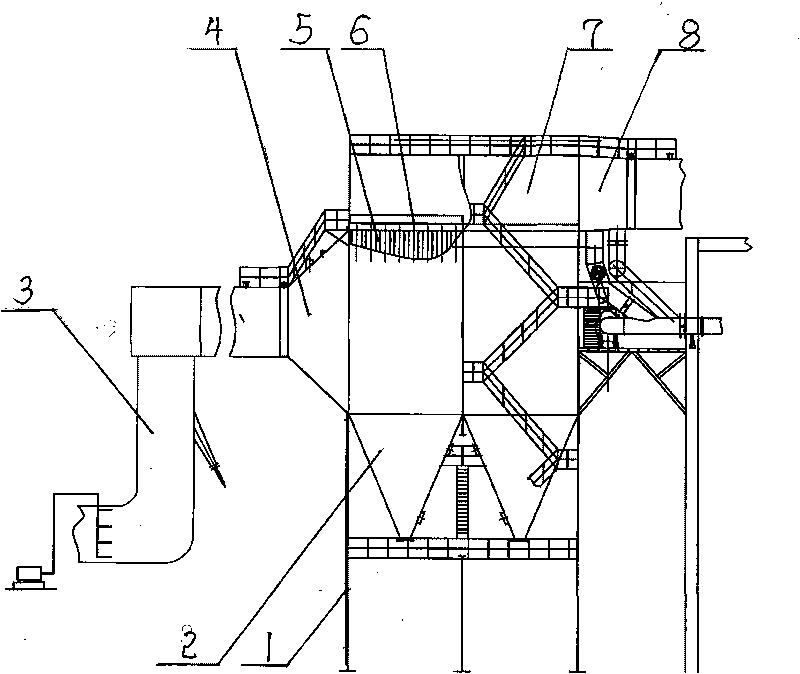

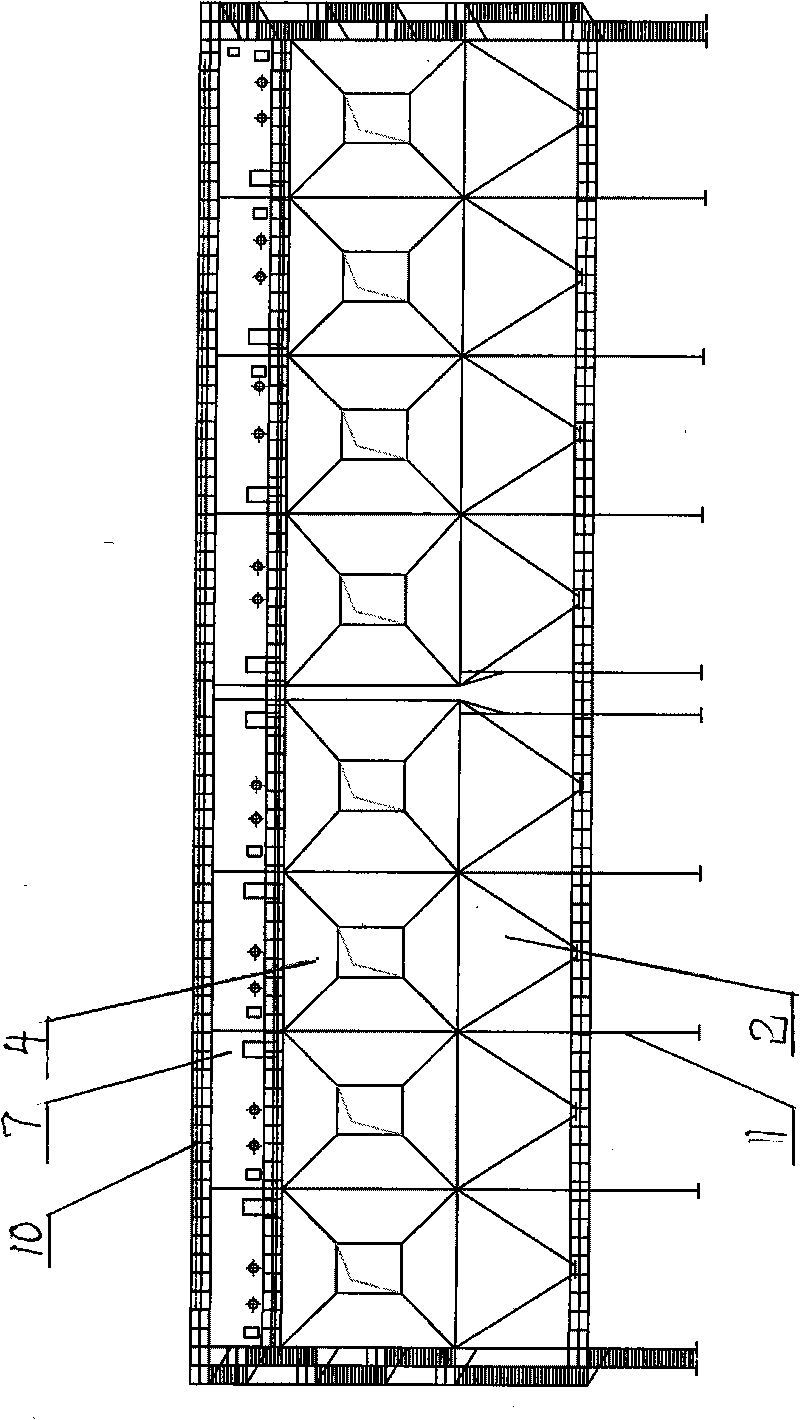

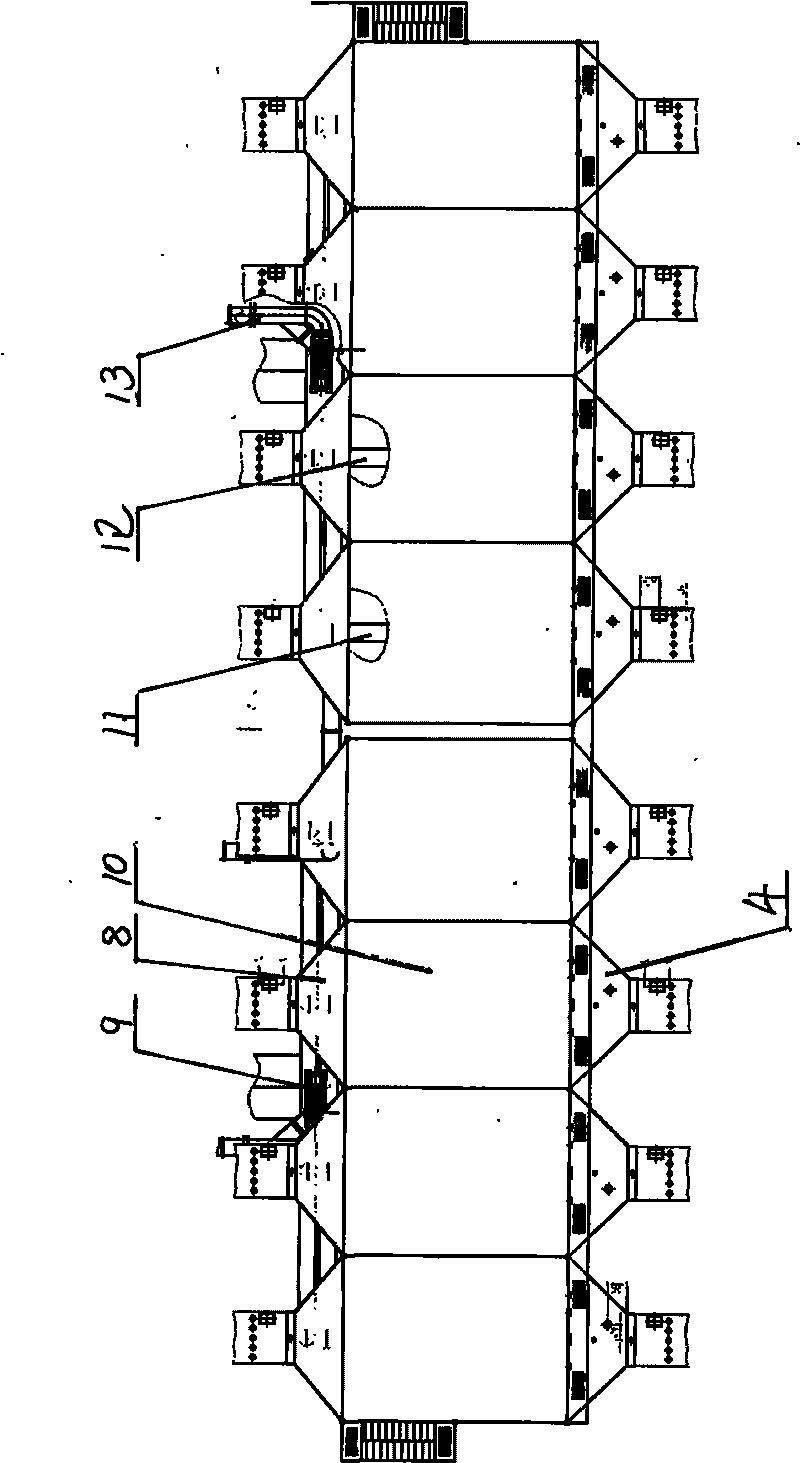

[0016] Such as figure 1 , 2 As shown in , 3, the bag filter of 600MW unit includes eight dust removal units connected in sequence. 7. There is a flower plate assembly 6 inside the box body 7, and a filter bag 5 is hung on the flower plate assembly 6. The flower plate assembly 6 and the filter bag 5 divide the box body into upper and lower chambers, and one side of the lower chamber of the box body is connected Imported smoke box 4 is arranged, and imported smoke box 4 is connected with generator set, and the upper cavity of the box body is connected with outlet smoke box 8, and outlet smoke box 8 is also connected with anti-blowing device 9 and air induction pipe 13.

[0017] A comprehensive and integrated construction method for a 600MW unit bag filter, including the following steps: Figure 4 As shown, the track 14 is installed on the ground, and the crane 15 is set on the track 14. The positions of the track 14 and the bag filter in the design basically coincide, making f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com