Roll breakage protecting control method for working roll of heavy and medium plate mill

A technology for protection and control of work rolls, applied in metal rolling, metal rolling, safety equipment of rolls, etc., can solve the problems of uneven bearing force, excessive bearing force, breakage of work rolls, etc., to reduce failures rate, increase efficiency, and improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

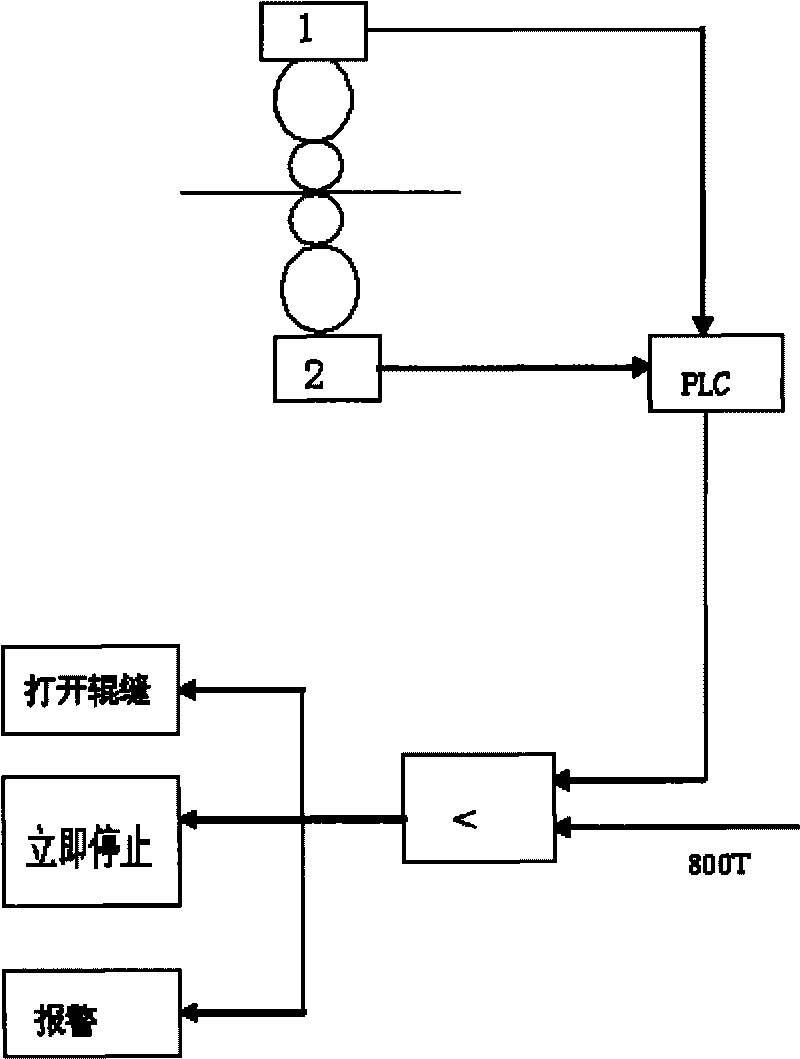

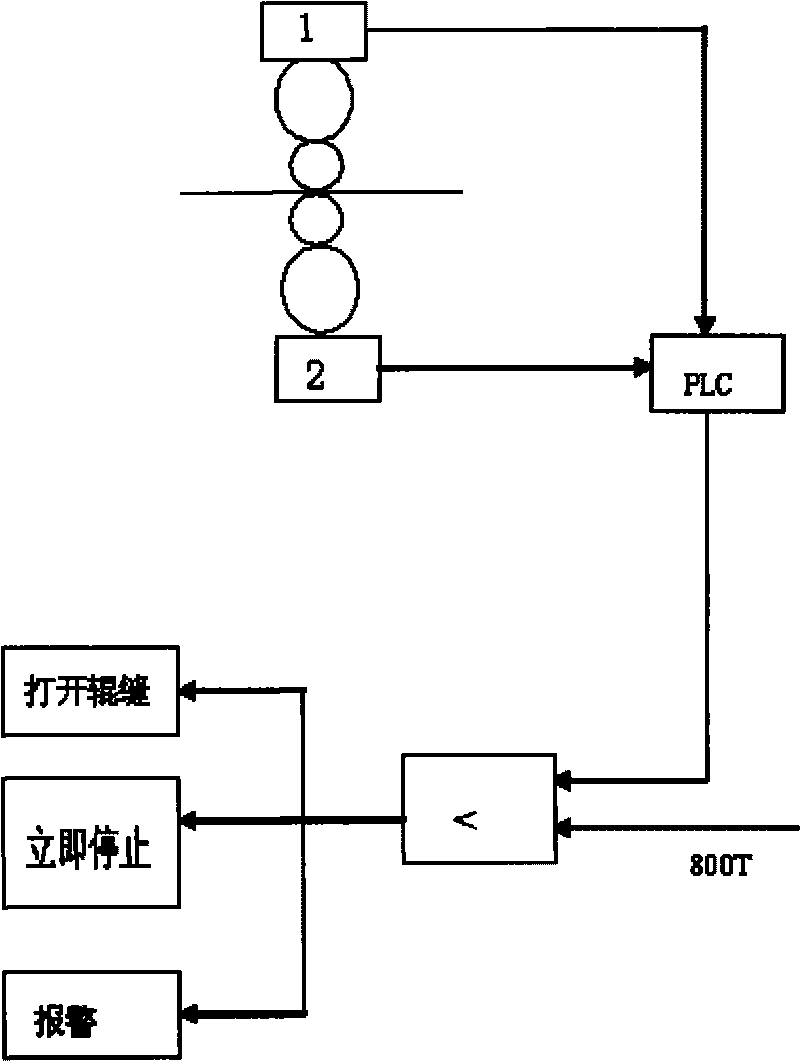

[0013] A method for protection and control of work roll breakage in medium and heavy plate mills, see figure 1 , Two pressure sensors are added on the AGC control hydraulic valve table, and the two pressure sensors are set on the transmission side and the operation side respectively, that is, the transmission side pressure sensor 1 and the operation side pressure sensor 2. And transmit the detected pressure signal to the rolling mill control PLC; the rolling mill control PLC multiplies the pressure detected by the pressure sensors on the transmission side and the operating side by the area of the AGC hydraulic cylinder respectively to obtain the pressure of the AGC cylinder; according to the transmission characteristics of the force, During the operation of the medium and heavy plate mill, the calculated pressure is the pressure acting on both sides of the work roll; compare the calculated two pressures on both sides of the work roll with the force detected by the pressure he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com