Large-diameter plastic pipe punching and cutting device

A cutting device, plastic pipe technology, applied in transportation and packaging, boring/drilling, drilling/drilling equipment, etc., can solve the problems of high labor intensity, low processing efficiency, low precision, etc., and achieve scientific structural design. Reasonable, improve processing efficiency, and ensure the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

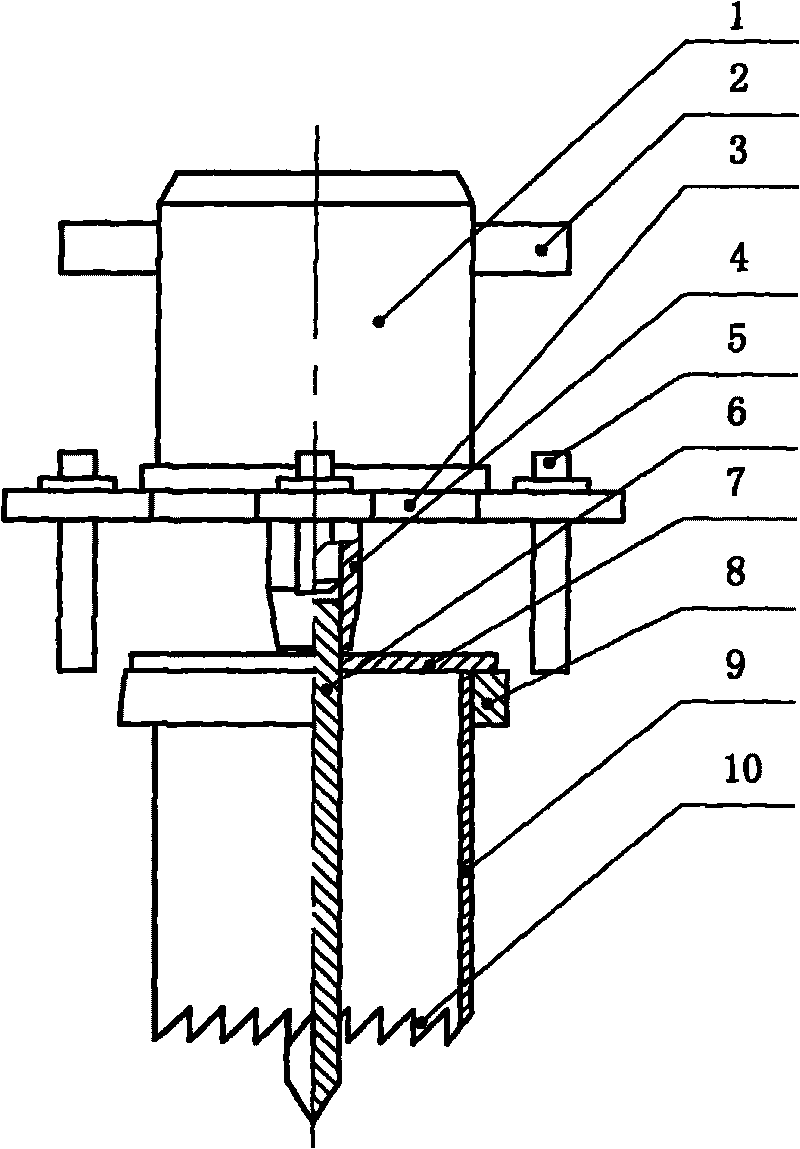

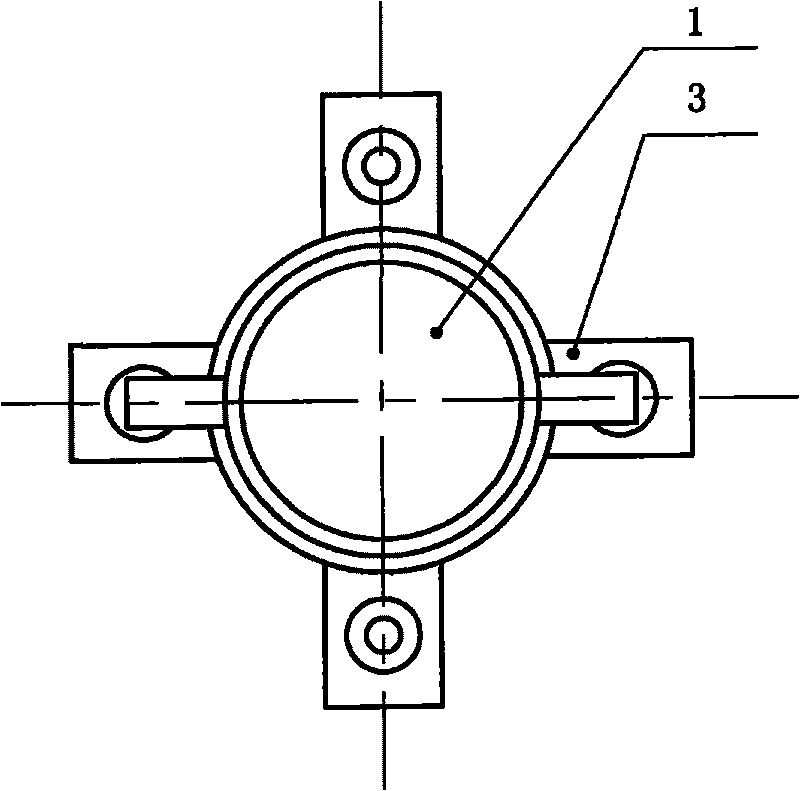

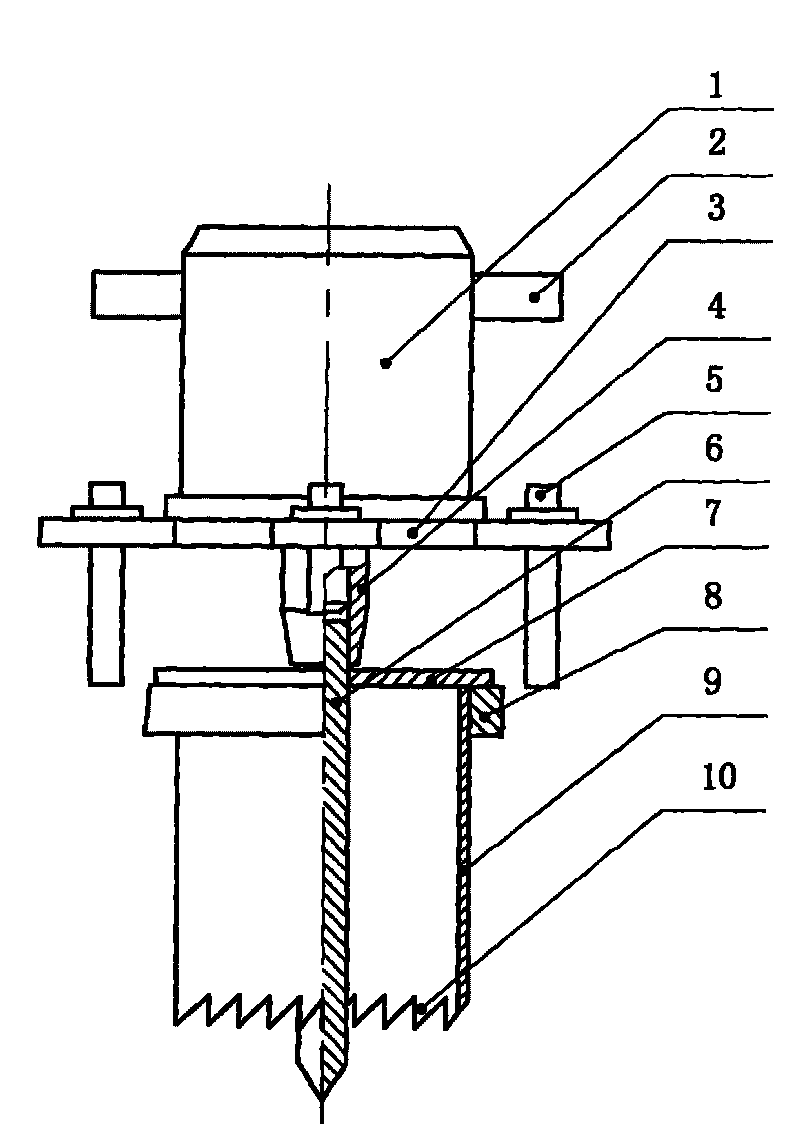

[0017] A large-diameter plastic pipe hole cutting device is innovative in that it includes a driving device 1 , a center positioning drill 6 and a rotary cutter 9 . The driving device is a driving motor or an air motor. The drive shaft of the drive motor shaft or the air motor passes through the drill bit fixture 4 coaxially fixed center positioning drill. The upper part of the central positioning drill is coaxially fixed with a cylindrical rotary cutter through a connecting plate 7. The lower bottom edge of the rotary cutter is provided with cutting teeth 10, and the tip of the central positioning drill protrudes from the lower bottom edge of the rotary cutter. external. A countersinking knife 8 is coaxially fixed on the outside of the up...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap