Optical path device of numeral control laser cutting machine

A digitally controlled laser and cutting machine technology, applied in laser welding equipment, optics, installation, etc., can solve problems such as difficult application, high cost, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

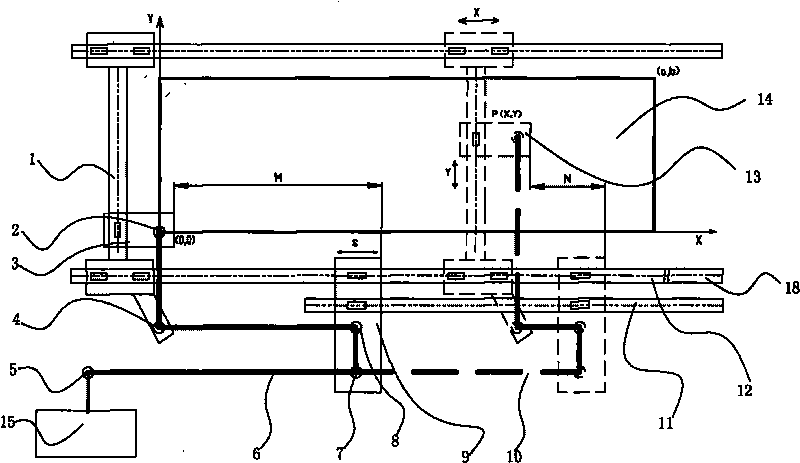

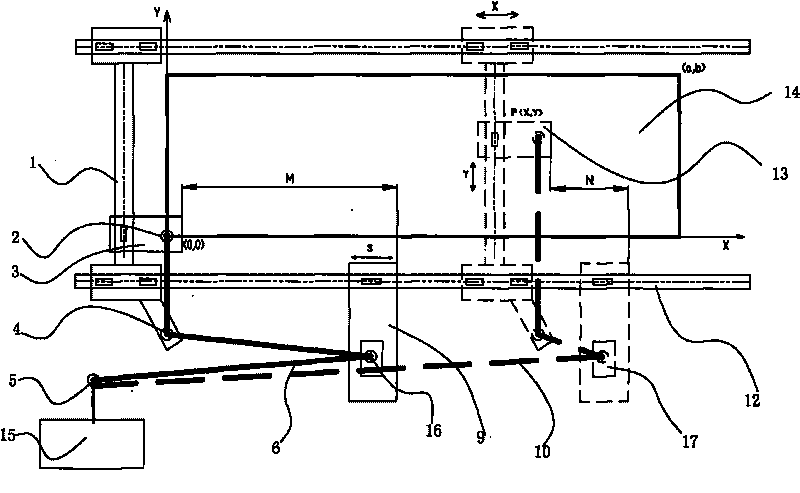

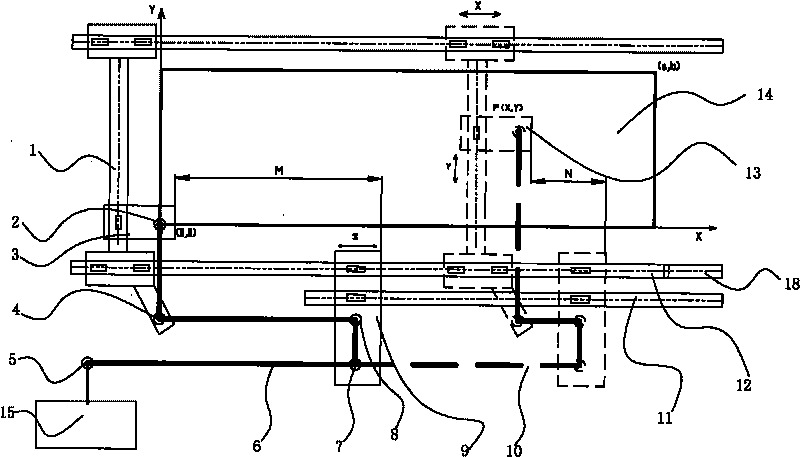

[0026] The present invention as figure 2 As shown, it includes a laser generator 15, a cutting head 2 that uses a lens to form a cutting laser spot on the surface of a workpiece, a conductive optical path device that connects the laser generator 15 and the cutting head 2, and a controller. It is also provided with an equal optical path device, etc. The optical path device includes a trolley 9 driven by a servo motor, at least one compensation mirror 16 arranged on the trolley 9 , and a Y-direction reciprocating mechanism 17 for the compensation mirror 16 . The servo motor is connected to the controller, and the compensating mirror 16 is set in the transmission light path in a meandering manner, and the transmission reflection mirror 5 and the reception reflection mirror 4 are arranged in the transmission light path. Dolly 9 is connected on the beam track 12.

[0027] The controller includes a memory storing a program for moving the optical path device according to the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com