Double-film bag making machine

A bag-making machine and double-layer film technology, applied in the direction of envelope/bag manufacturing machinery, paper/cardboard containers, containers, etc., to achieve the effect of convenient operation, good effect and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

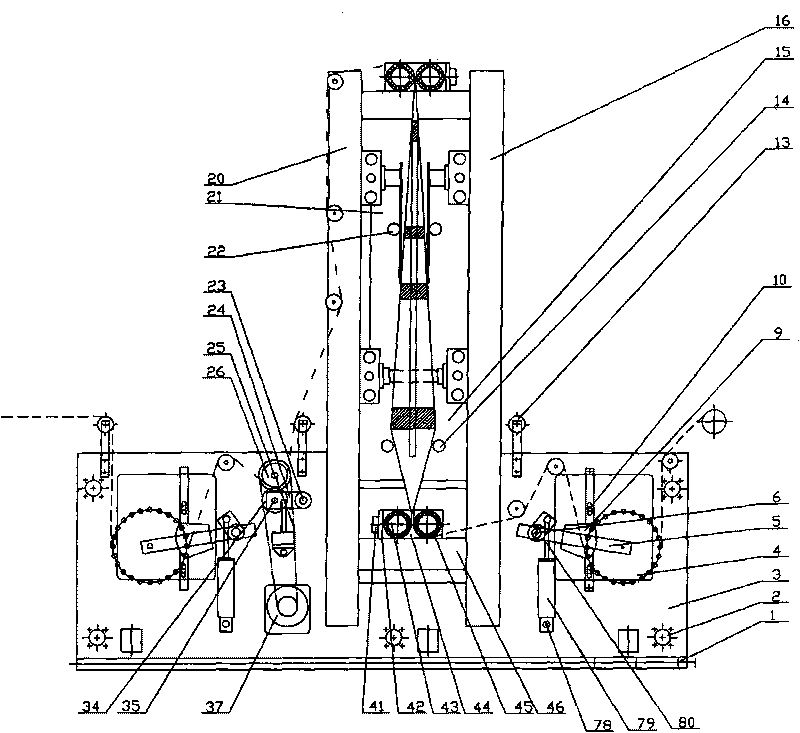

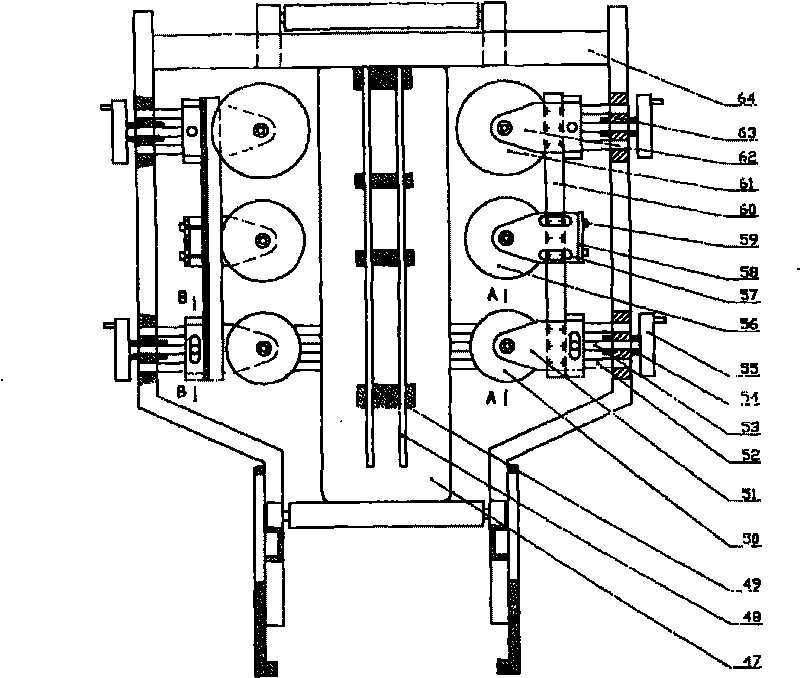

[0039] figure 1 It is the overall structure schematic diagram of the double film bag-making machine of the present invention, as figure 1 As shown, the inner layer film used in the present invention, that is, the tube film, is placed at the far right end of the machine, fixed on the air shaft in the form of a roll film, and the air shaft is repositioned on the movable frame of the first discharging device a. The frame is equipped with a constant tension control system and a photoelectric automatic centering and deviation correction system composed of a fixed frame. The film material of the inner film is sent out by the discharge motor through the synchronous belt pulley to the discharge rubber traction roller assembly. Its speed control (fine adjustment) is completed by the subsequent tension pendulum roller. The tension pendulum ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com