Special fixture for hoisting rectangular section steel column and hoisting method by using same

A technology with a rectangular section and a special fixture, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of difficulty in finding the direction of the section of the steel column, difficulty in cutting off the lifting lugs at high altitude, and damage to the surface quality of the steel column, so as to reduce the high altitude. Operation risk, improving hoisting efficiency, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

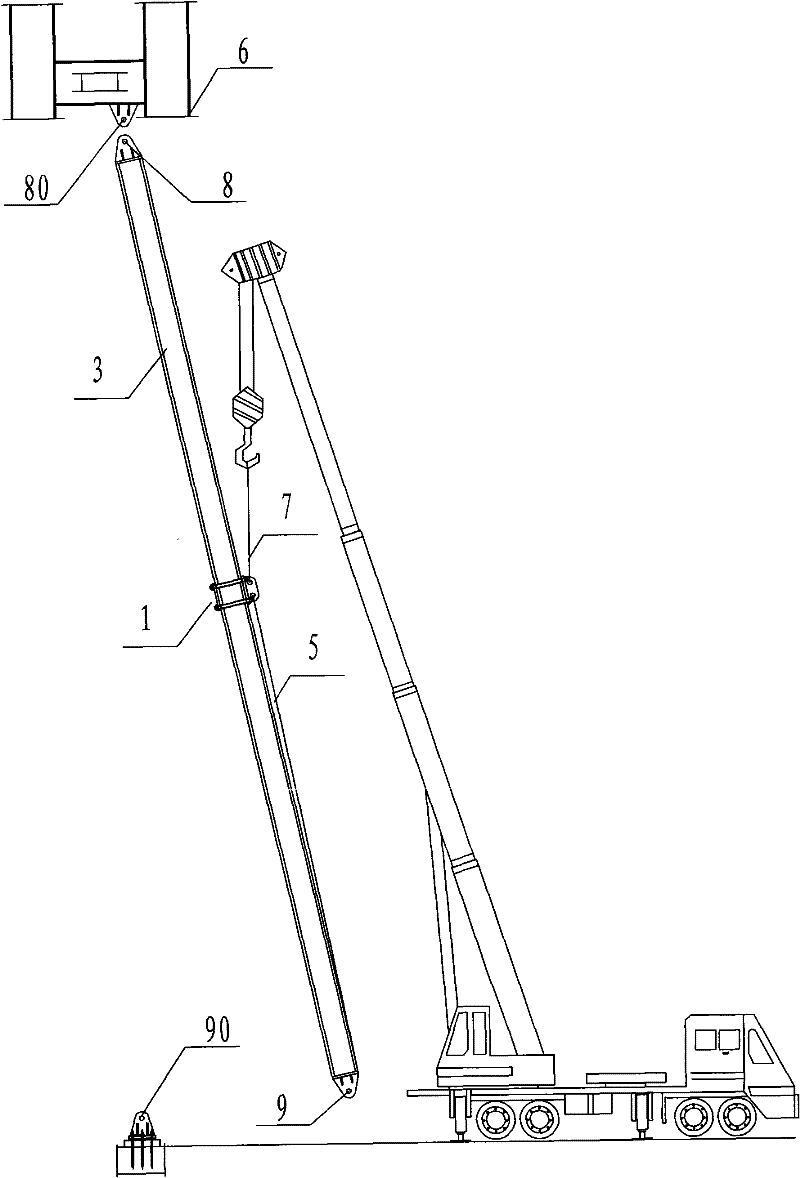

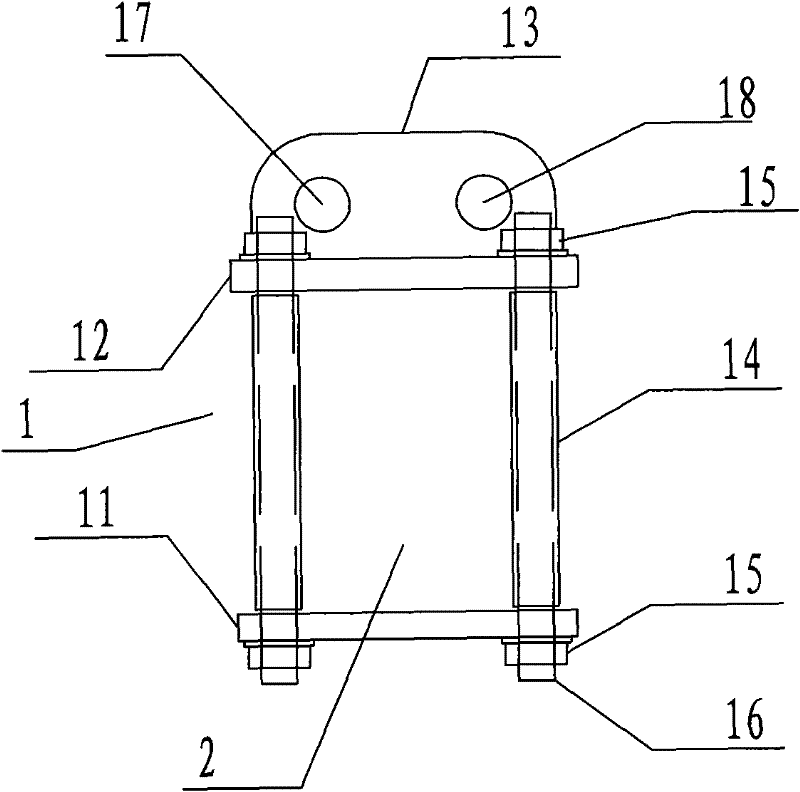

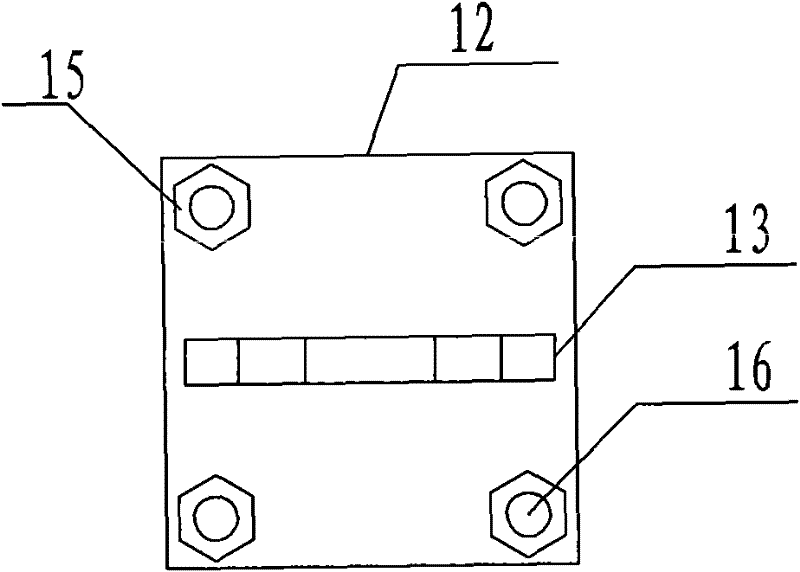

[0019] refer to figure 1 , figure 2 and image 3 , a special fixture for hoisting a steel column with a rectangular section according to the present invention, comprising a detachable fixture main body 1, the main body 1 of the fixture is provided with a matrix-shaped space 2 for accommodating a steel column with a rectangular section 3, and the inner space of the matrix-shaped space 2 The net size is slightly larger than the cross-sectional dimensions of the rectangular steel column, so that the clamp can slide on the steel column. The centerline of the main side of the clamp body 1 is provided with a lifting hole 17 and a limit hole 18 through the lug plate 13 .

[0020] Further, as a preferred embodiment, the detachable clamp body 1 includes an upper panel 12, a lower panel 11 and four screw rods 16, and the four screw rods 16 are locked and connected between the upper and lower panels 12, 11 through nuts 15 , the middle parts of the four screw rods 16 are covered with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com