Film treatment method for wastewater produced by synthetic rubber

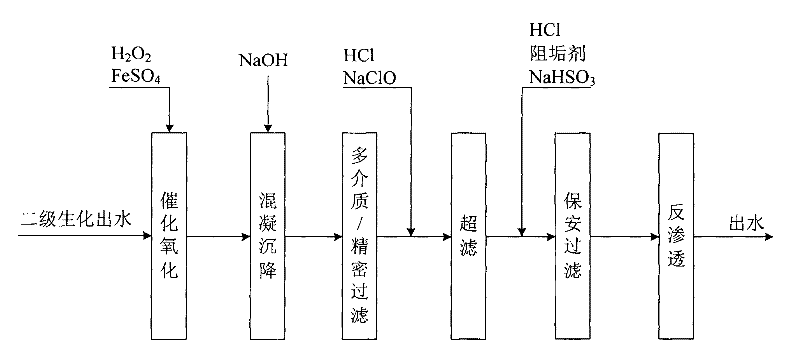

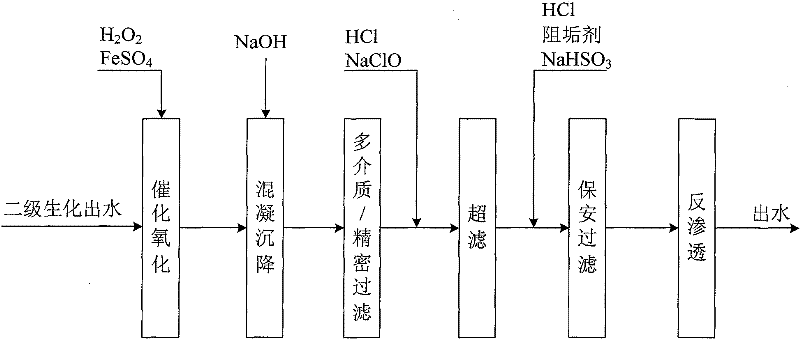

A technology for producing wastewater and synthetic rubber, which is applied in the fields of water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Synthetic rubber production wastewater (including butadiene rubber and styrene-butadiene rubber production wastewater) after secondary biochemical treatment in a factory has a pH of 6.2, a COD of 101mg / L, a TOC of 31.6mg / L, and a conductivity of 4460μm / cm.

[0042] The wastewater is taken from the effluent of the secondary sedimentation tank, and firstly undergoes catalytic oxidation treatment. The catalytic oxidation conditions are: reaction temperature 25°C, reaction pressure normal pressure; 27.5% hydrogen peroxide is added to the wastewater with a dosage pump, of which H 2 o 2 The weight ratio to the wastewater TOC is 5.0; add ferrous sulfate to the wastewater, where Fe 2+ H in the oxidizing agent 2 o 2 The weight ratio is 0.8; aeration is used for stirring and mixing, and the reaction residence time is 120min.

[0043] The effluent is catalyzed and oxidized, pressurized into the coagulation device, mixed with 15% NaOH solution through the pipeline mixer, and a...

Embodiment 2

[0049] The synthetic rubber production wastewater of a factory after secondary biochemical treatment has a pH of 6.7, a COD of 90 mg / L, a TOC of 27 mg / L, and an electrical conductivity of 3850 μm / cm.

[0050] Catalytic oxidation treatment is carried out on the wastewater, and the catalytic oxidation conditions are: removal of H 2 o 2 The weight ratio to the wastewater TOC is 3.0; add ferrous sulfate to the wastewater, where Fe 2+ H in the oxidizing agent 2 o 2 The weight ratio is 0.4; the reaction residence time is 90min.

[0051] Use 15% NaOH solution to adjust the pH of the catalytic oxidation water to 10.5, use aeration and coagulation for 10 minutes, and enter the sedimentation tank for slag water separation. The rising flow rate of the sedimentation tank is 1m / h.

[0052] The effluent from the sedimentation tank first passes through a 100μm laminated filter, and the pH of the effluent from the filter is roughly adjusted to 8.5 with hydrochloric acid, and 5mg / L of sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com