Intelligent automatic washing machine

A washing machine and automatic technology, applied in the field of washing procedures, can solve the problems of inability to clean dirt, troublesome laundry process, high labor intensity, etc., and achieve the effects of easy production, low processing cost, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

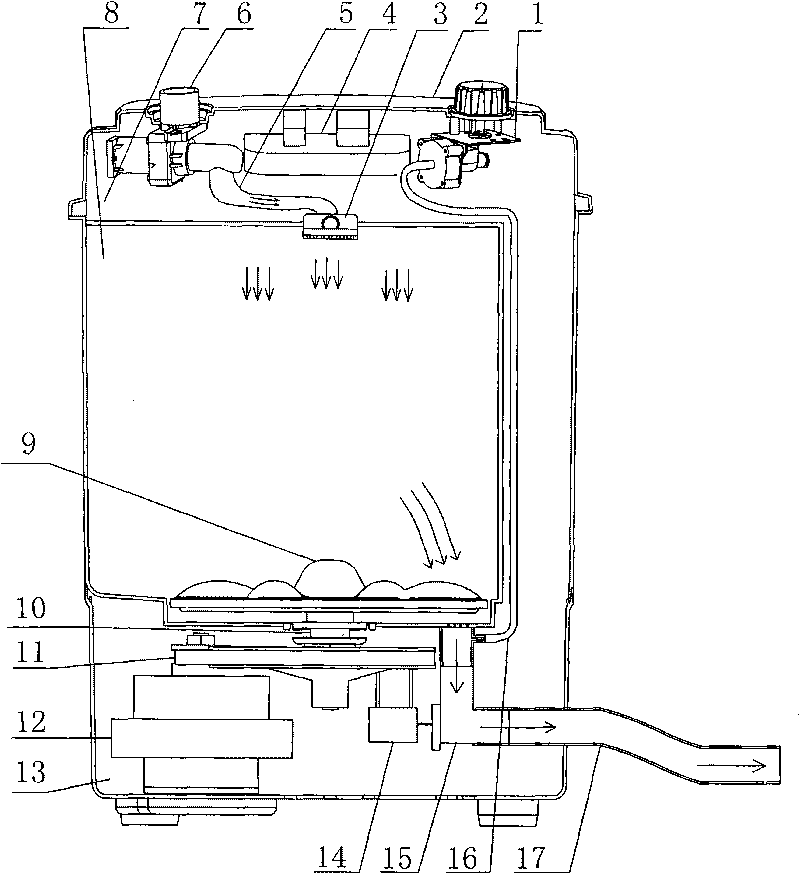

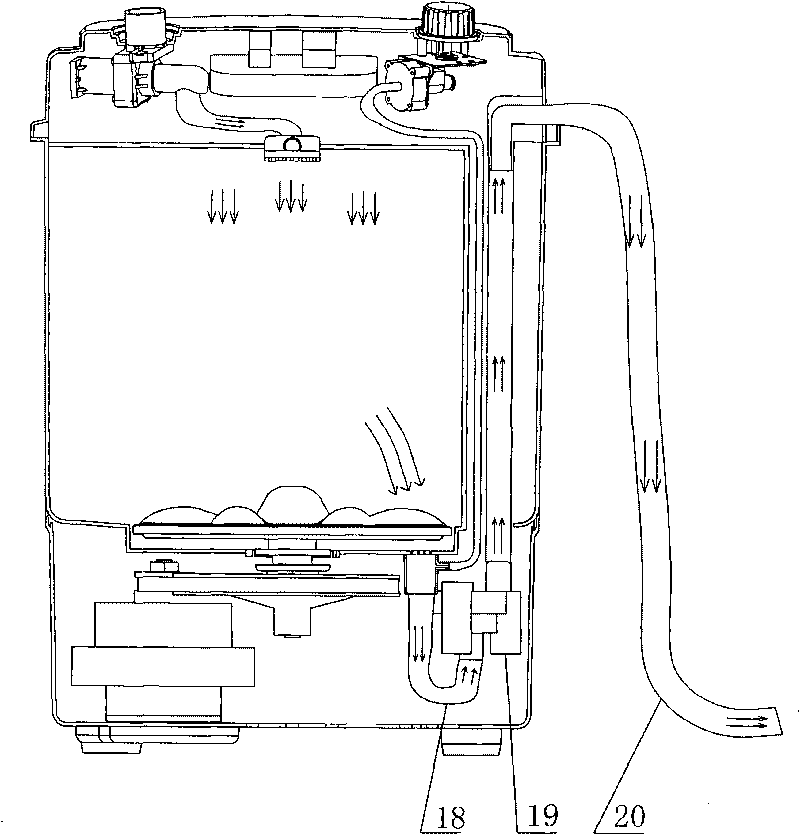

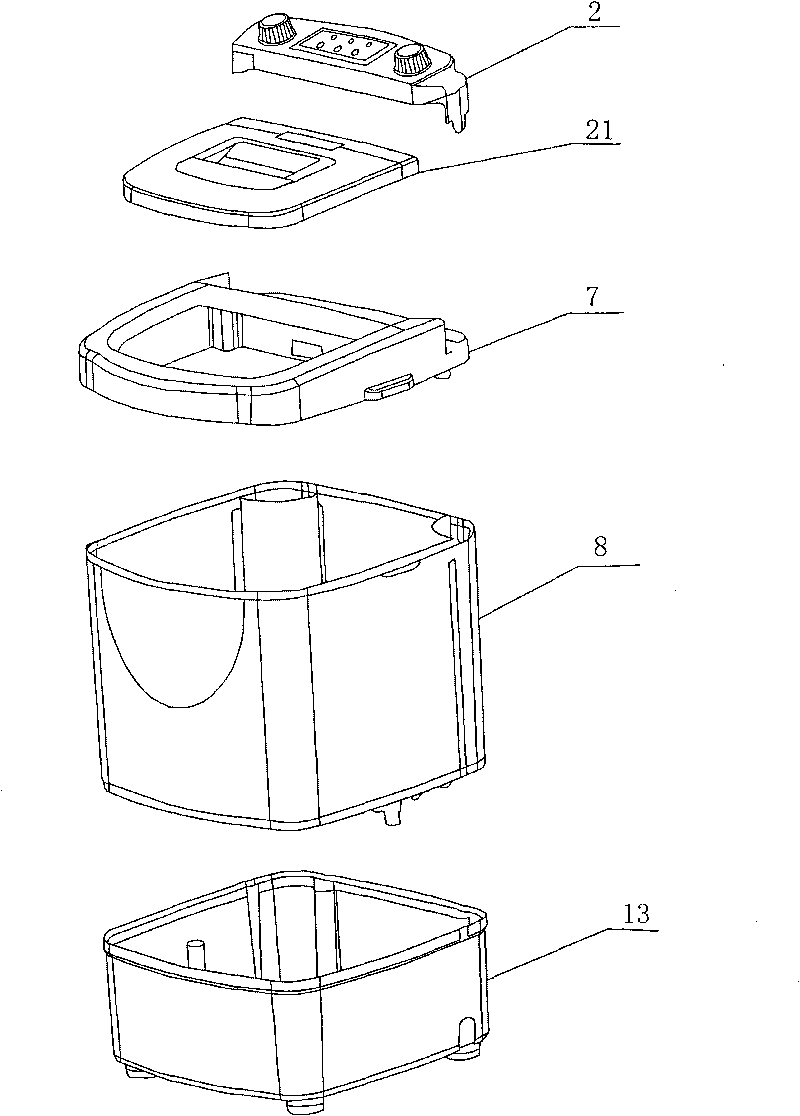

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] Improve the washing program on the computer board of the automatic washing machine, delete the dehydration program, and add the spraying, rinsing and drainage steps: water intake→washing→drainage, repeat the above washing procedure 2 to 3 times, and then add the spraying, rinsing and drainage procedure .

[0021] Washing machine wash programs include:

[0022] Water intake: controlled by the computer control panel, open the water intake valve to start water intake;

[0023] Washing: When the water intake reaches the set standard, stop the water intake and start washing. The washing speed and time are set according to the program;

[0024] Drainage: After washing, it is controlled by the computer control panel, and the tractor opens the drain valve to drain down, or the electromagnetic water pump to drain up.

[0025] According to the set washin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com