Multifunctional fabric and preparation method thereof

A multi-functional, fabric technology, applied in the field of fabrics worn by people, can solve the problem of non-supply and achieve the effect of wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

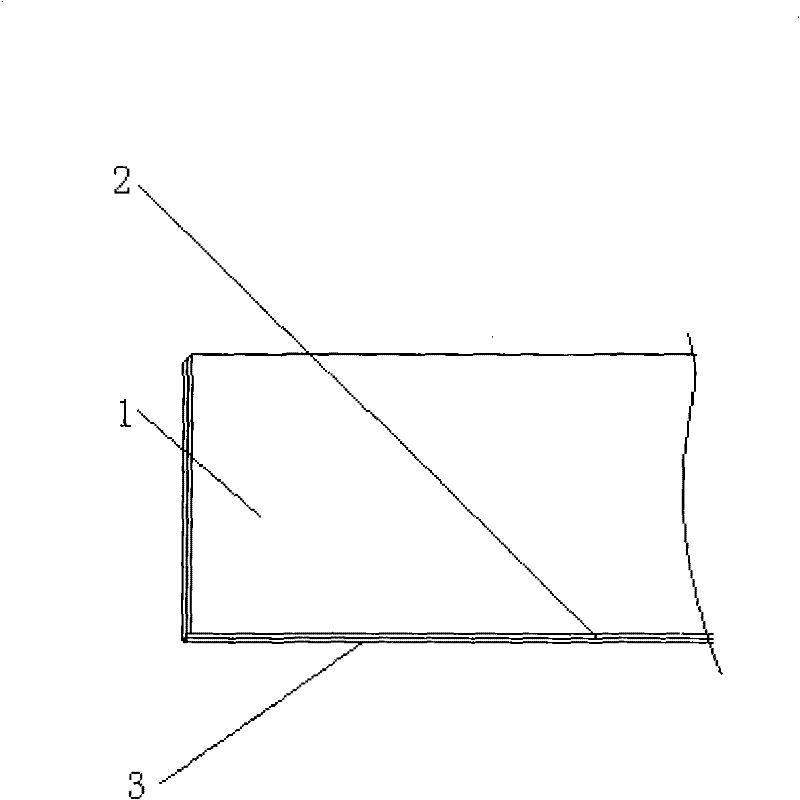

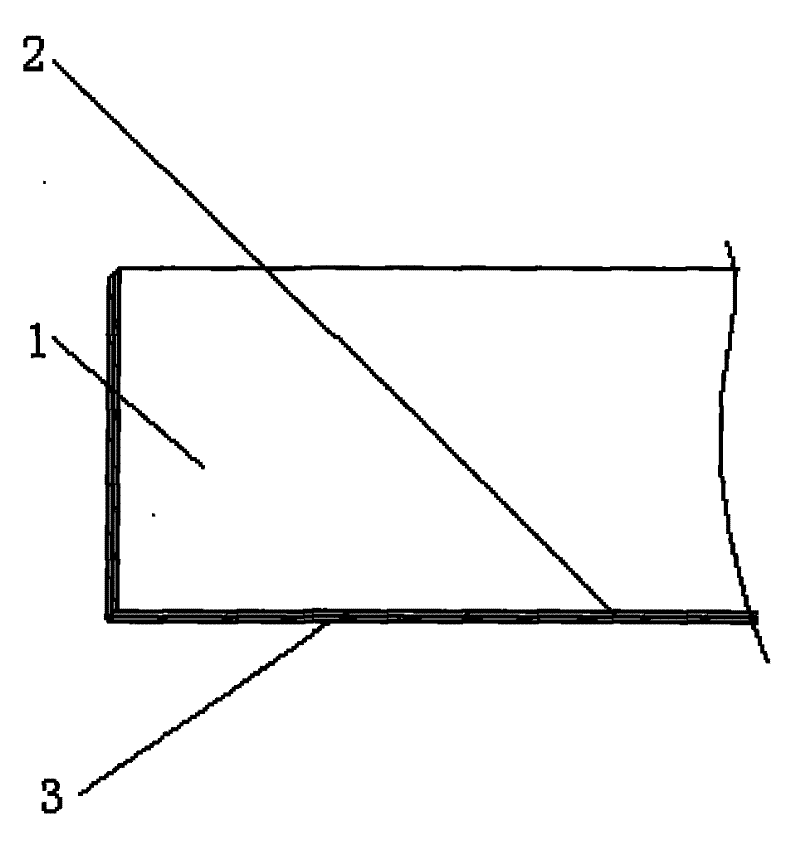

[0020] like figure 1 As shown, a multifunctional fabric is made of polyester knitted fabric, polytetrafluoroethylene film, and bamboo charcoal anion PU film. One side surface of the polyester knitted fabric 1 is pasted with polytetrafluoroethylene film 2, Bamboo charcoal negative ion PU membrane3.

[0021] The preparation method of above-mentioned fabric, comprises the following steps:

[0022] (1) In this embodiment, the moisture-responsive hot-melt adhesive produced by Henkel in Germany is selected. The melt is used as an adhesive for film lamination. First, a polytetrafluoroethylene film (thickness of the film is 0.04mm) is pasted. After the film is pasted, the base fabric is rolled up and matured for about 48 hours at a humidity of about 70% and an environment of about 25°C. , after inspection;

[0023] (2) at a temperature of 70-90°C, the surface of the polytetrafluoroethylene film is pasted on the cloth obtained in step (1), coated with the hot melt adhesive as descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com