Split torque compound planetary drivetrain for wind turbine applications

一种风力涡轮机、复合行星齿轮的技术,应用在风力发动机、齿轮传动装置、风力发电机组件等方向,能够解决降低风力涡轮机扭矩密度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

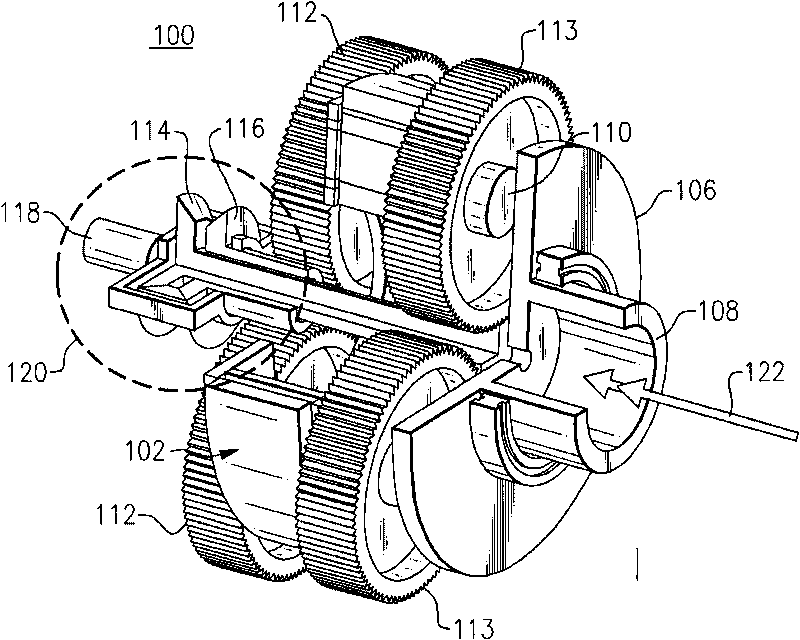

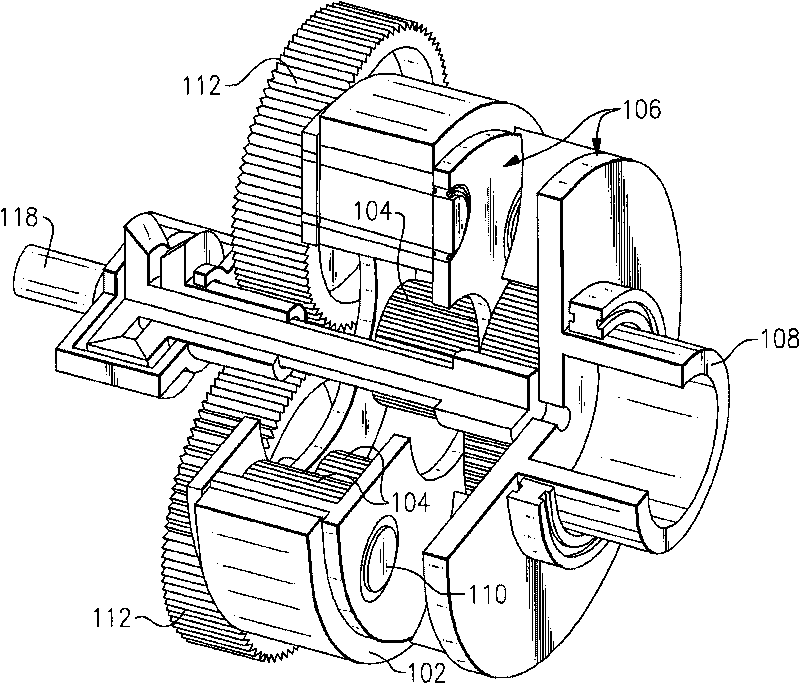

[0066] figure 2 A torque-split planetary gear drive 100 according to one embodiment of the invention is shown, while image 3 Further details of the planet carrier 106 depicted in FIG. 1 are shown according to one embodiment of the invention. The gear drive 100 includes a stationary ring gear 102 meshing with more than three planet gears 104 , and a rotating planet carrier 106 . A first stage comprising a plurality of planet gears 104 is driven by an input shaft 108 . The first stage drives the second stage through a common gear shaft (pin) 110 . The second stage planetary gears 112 , 113 in turn mesh with one or more sun gears 114 , 116 via an output shaft 118 .

[0067] More specifically, and continue to see figure 2 and image 3, the torque-split compound planetary gear drive 100 includes a stationary ring gear 102 . The planet carrier 106 , including at least one carrier arm, is configured to rotate about a central axis 122 of the ring gear 102 in response to an inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com