Multidirectional rotating platform

A rotating platform, multi-directional technology, applied in the direction of machine/support, optics, instruments, etc., can solve the problems of complex drive system structure, susceptibility to electromagnetic interference, high cost, etc., and achieve the effect of small size, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

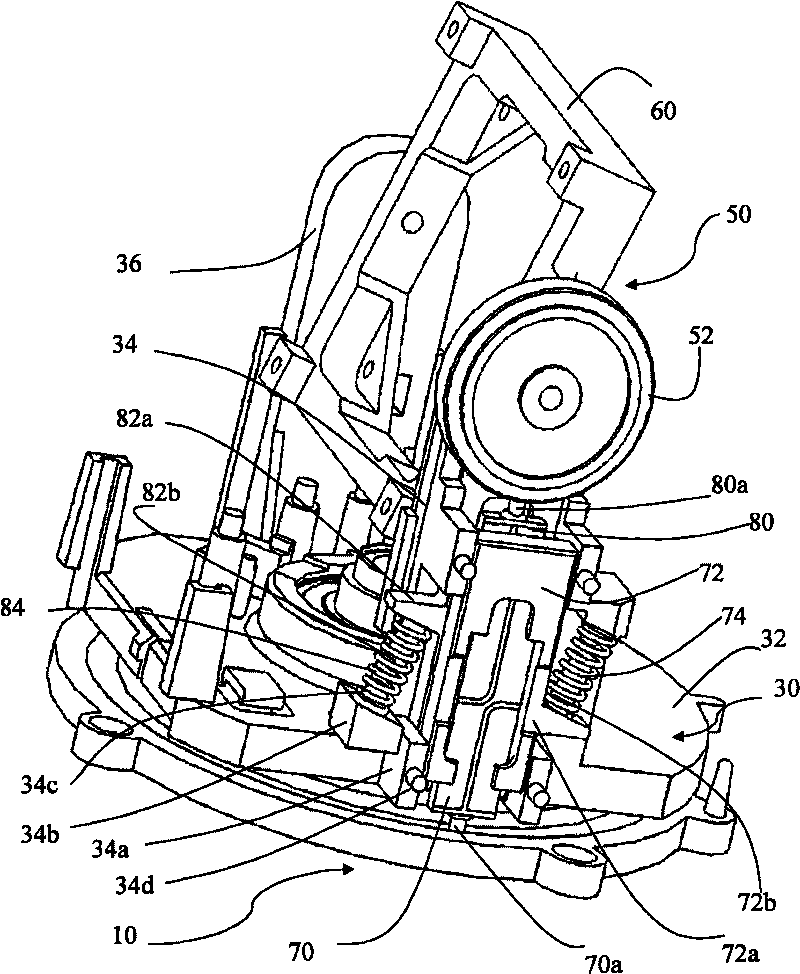

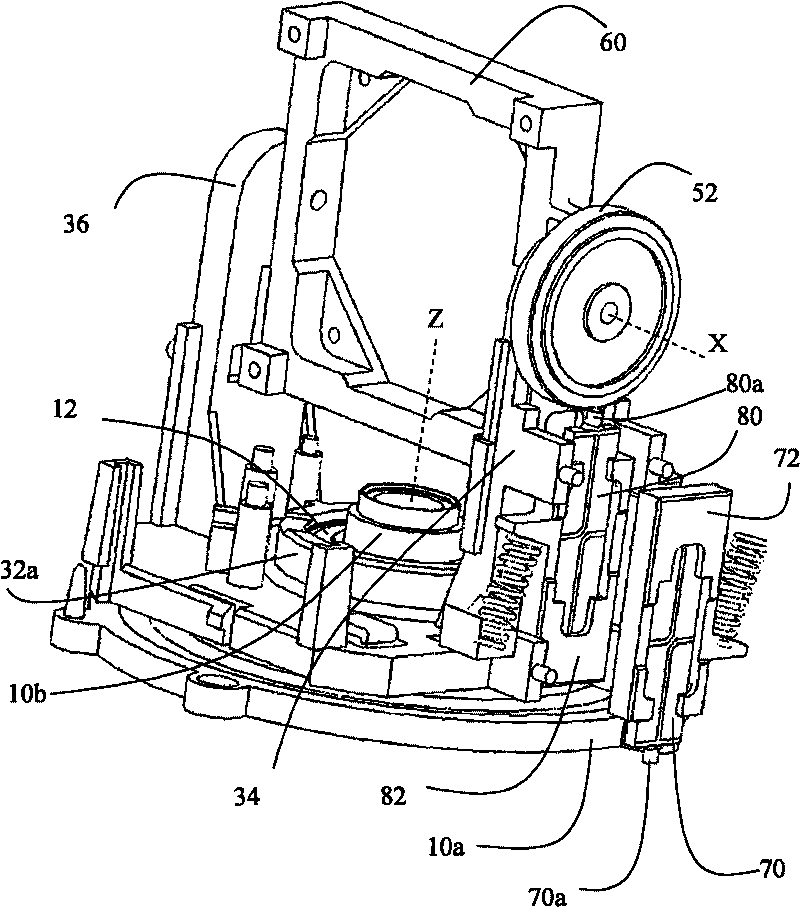

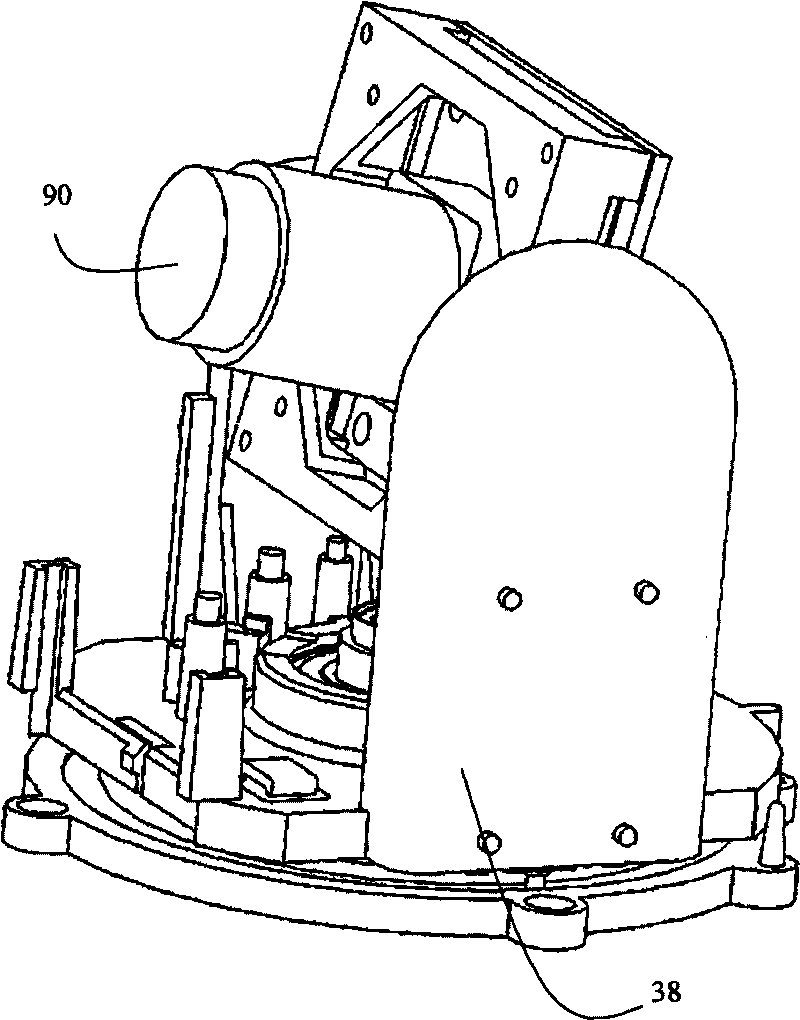

[0016] See figure 1 versus figure 2 A multi-directional rotating platform according to an embodiment of the present invention includes a base 10, a first platform 30, and a second platform 50.

[0017] The base 10 includes a disc-shaped body 10a and a shaft 10b extending perpendicularly from a central position on one side of the disc-shaped body 10a.

[0018] The first platform 30 includes a base plate 32 and two supporting seats 34 and 36 extending upward from two opposite sides of the base plate 32. A mounting portion 32 a with a hollow structure is provided in the center of the base plate 32, and the shaft 10 b of the base 10 is mounted in the mounting portion 32 a of the base plate 32 through a bearing 12.

[0019] The second platform 50 includes a rotating body such as a turntable 52. The turntable 52 is rotatably mounted on one of the support seats 34 of the first platform 30 through a rotating shaft, and a mounting seat 60 is mounted on the first platform 30. Between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com