Method and device for detecting shrinkage and cracking performance of cement-based material

A technology of cement-based materials and detection methods, which is applied in the direction of measuring devices, analyzing materials, and optical devices, etc., can solve the problems of being easily affected by subjective factors of operators, complicated operation process, and insufficient precision, etc., and achieves the reduction of calculation amount and economical efficiency. Good performance and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

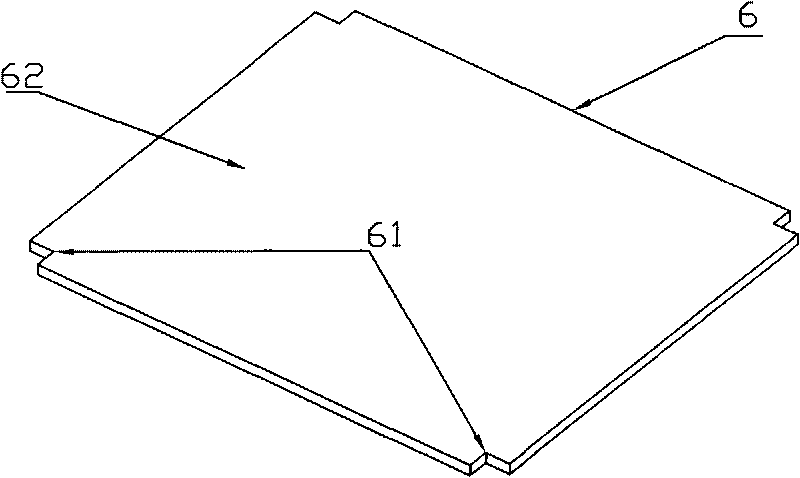

[0058] The invention adopts digital image processing technology, utilizes related devices to collect, transmit, process, and analyze digital images, calculates the characteristics of shrinkage and cracking of materials, describes the development trend of shrinkage and cracking, and aims at the composition of cement concrete, which affects other raw materials. The degree and trend of shrinkage and cracking development are evaluated, so as to obtain the detection and evaluation results of material shrinkage and cracking performance.

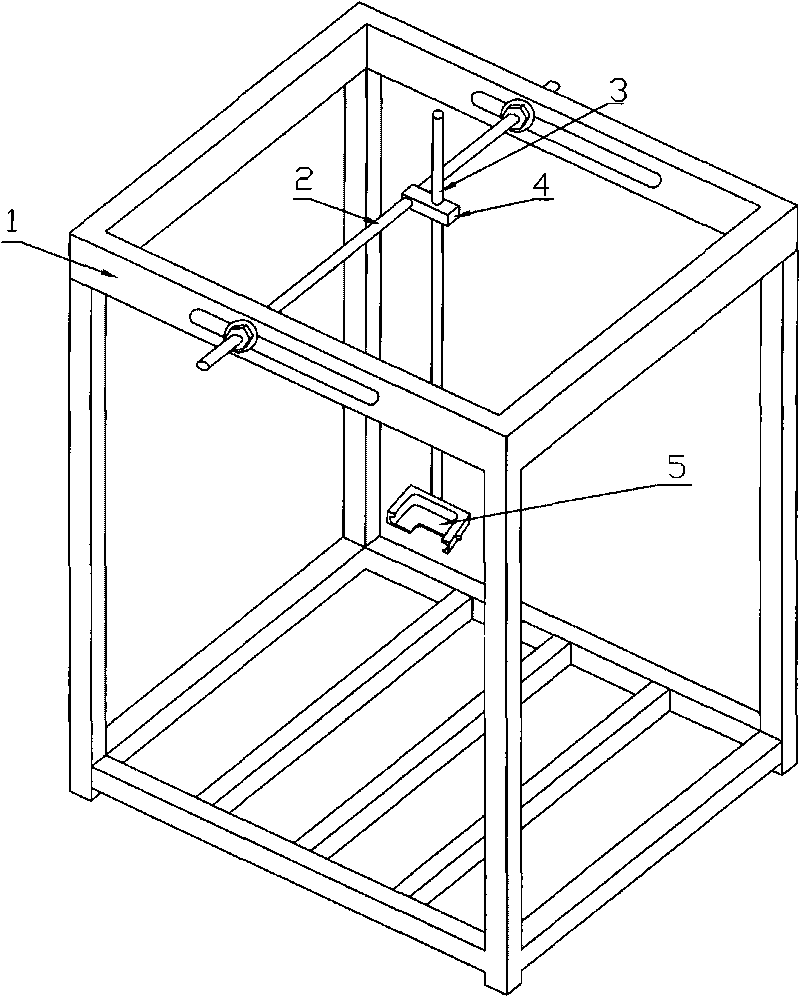

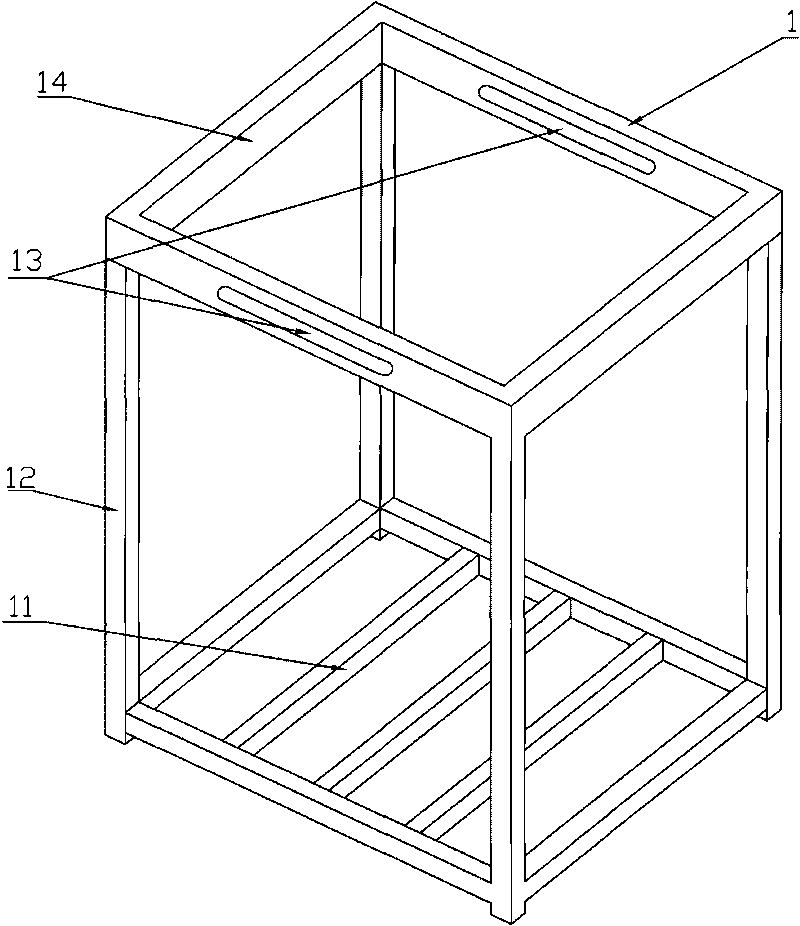

[0059] 1. Cement-based material shrinkage and cracking performance testing and evaluation system

[0060] The present invention is based on the digital image processing shrinkage cracking performance detection system of cement-based materials, its basic composition can be found in figure 2 As shown, it mainly includes five units such as image acquisition, image processing, analysis and evaluation, result display, and communication. Among them, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap