Acoustic surface wave gas sensor and manufacturing method thereof

A gas sensor and surface acoustic wave technology, which is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze fluids, etc., can solve the problems of three-stroke reflected signal interference, etc., and achieve the effects of easy signal processing, noise suppression, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

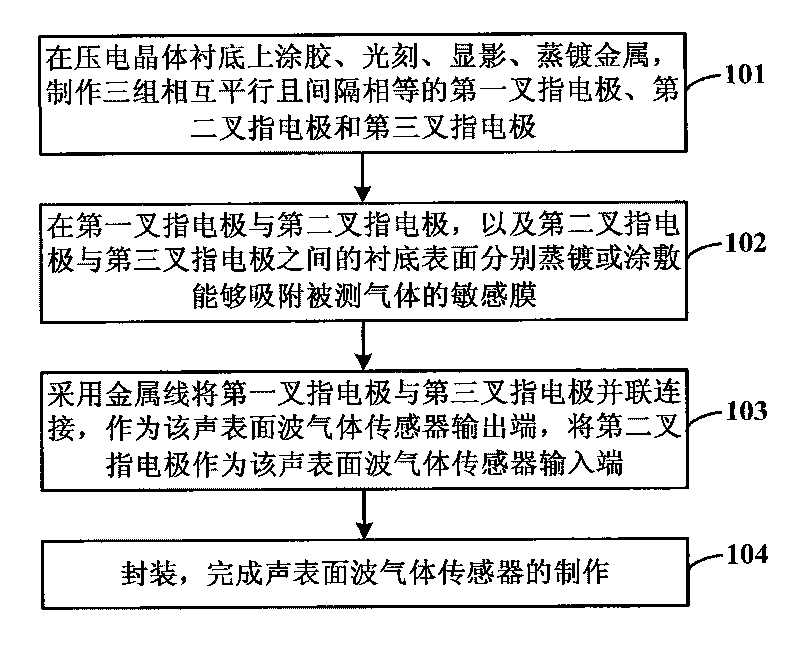

[0033] Such as figure 1 as shown, figure 1 It is a flowchart of a method for making a surface acoustic wave gas sensor provided by the present invention, and the method includes:

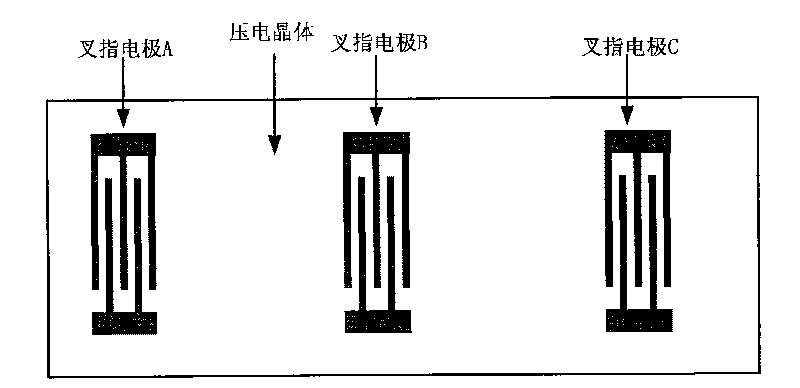

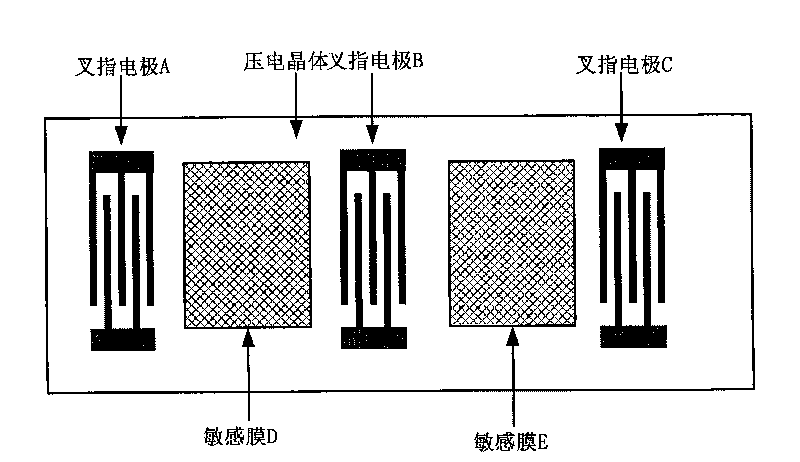

[0034] Step 101: Apply glue, photolithography, develop, and vapor-deposit metal on the piezoelectric crystal substrate, and make three sets of first interdigital electrodes (interdigital electrodes A) and second interdigital electrodes (interdigital electrodes A) parallel to each other and equally spaced. Finger electrode B) and the third interdigital electrode (interdigital electrode C); as figure 2 As shown, the piezoelectric crystal substrate can be a quartz substrate, a lithium niobate substrate or a lithium germanate substrate, etc. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com