Removal method of water vapor on crystal wafer surface

A chip and water vapor technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of incomplete water vapor removal, and achieve the effect of uniformity improvement and wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

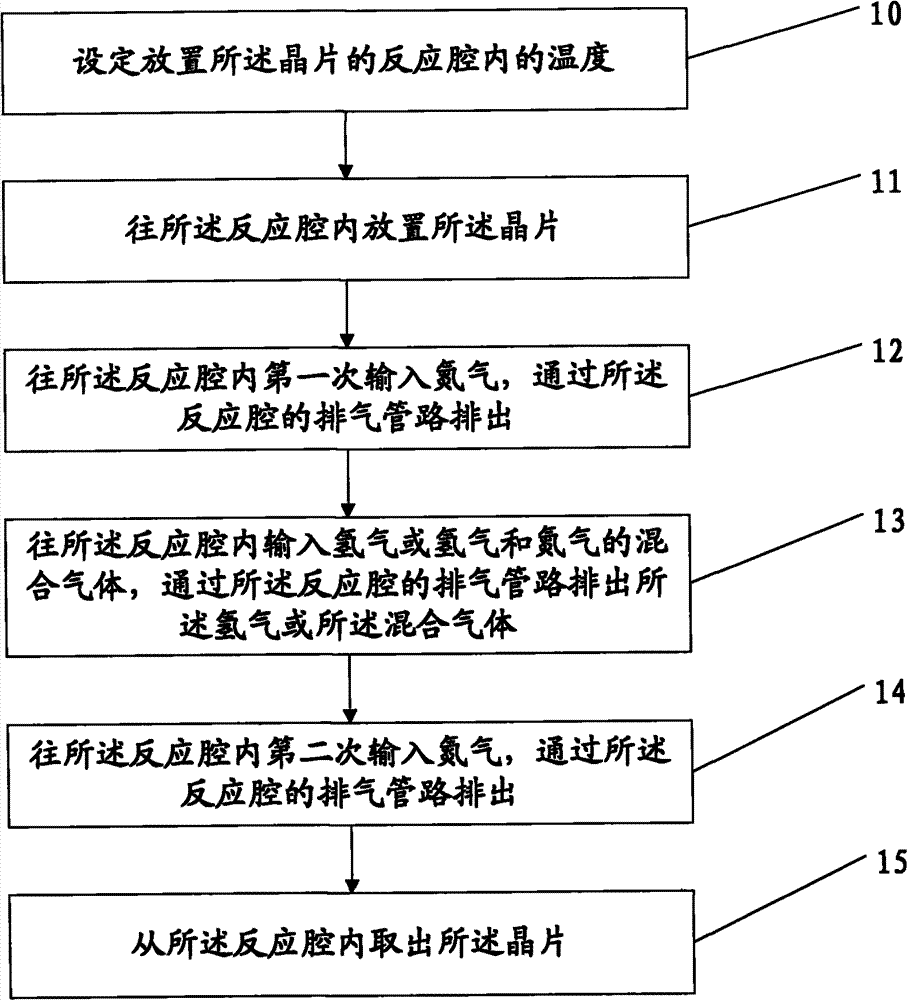

[0015] First, please refer to figure 1 , figure 1 It is a flowchart of a method for removing water vapor from the surface of a wafer of the present invention. As can be seen from the figure, the present invention includes the following steps: Step 10: Setting the temperature in the reaction chamber where the wafer is placed, the temperature in the reaction chamber The range is 400 degrees Celsius to 800 degrees Celsius, preferably, the temperature in the reaction chamber is 500 degrees Celsius; Step 11: Place the wafer in the reaction chamber, and the wafers placed in the reaction chamber are generally placed in a quartz boat and then placed in the reaction chamber; step 12: input nitrogen into the reaction chamber for the first time, and discharge it through the exhaust pipe of the reaction chamber. The time for the first nitrogen input is 5 minutes, and the input The nitrogen gas is 20 liters; step 13: input hydrogen or the mixed gas of hydrogen and nitrogen into the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com