Light-emitting diode drive circuit and transistor switching module thereof

A transistor switch, light-emitting diode technology, applied in circuit layout, lamp circuit layout, light source and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

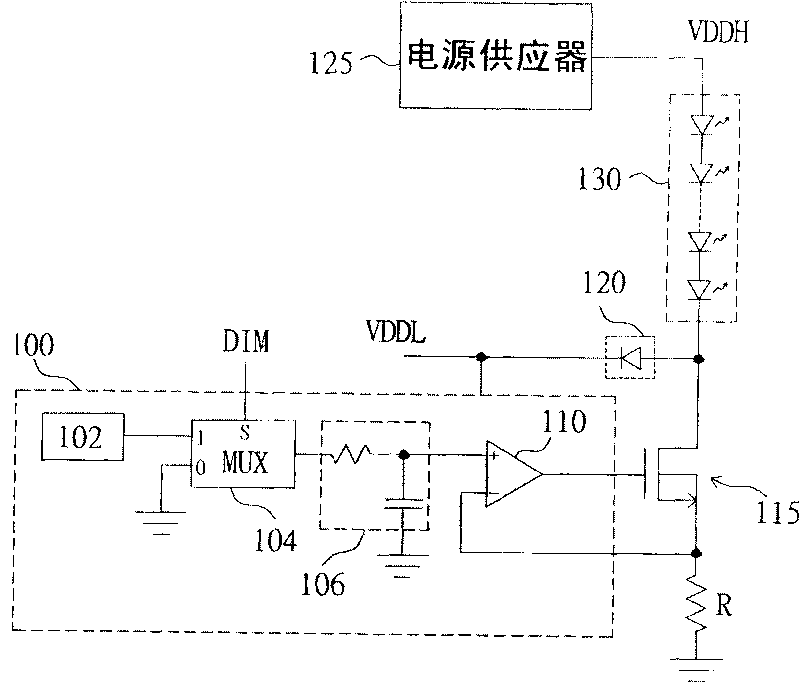

[0034] Please refer to figure 2 , is a schematic circuit diagram of a transistor switch module used in a light emitting diode driving device according to a preferred embodiment of the present invention. The LED driving device includes a dimming control unit 100 , a transistor switch 115 , a voltage clamping element 120 , a power supply 125 and a LED module 130 . The power supply 125 is coupled to one end of the LED module 130 to provide a driving voltage VDDH to drive the LED module 130 to emit light. The transistor switch 115 has a control terminal, a first terminal and a second terminal, the first terminal is coupled to the light-emitting diode module 130, the second terminal is coupled to a reference potential (for example: ground), the control terminal receives the signal from the dimming control unit 100 generates a control signal. The dimming control unit 100 includes a reference voltage generator 102 , a multiplexer 104 , a filter circuit 106 and an error amplifier 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com