Self-operated thermostatical gas distributor

A self-operated, constant temperature technology, applied in clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve problems such as easy damage, and achieve the effect of reliable work and not easy to damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

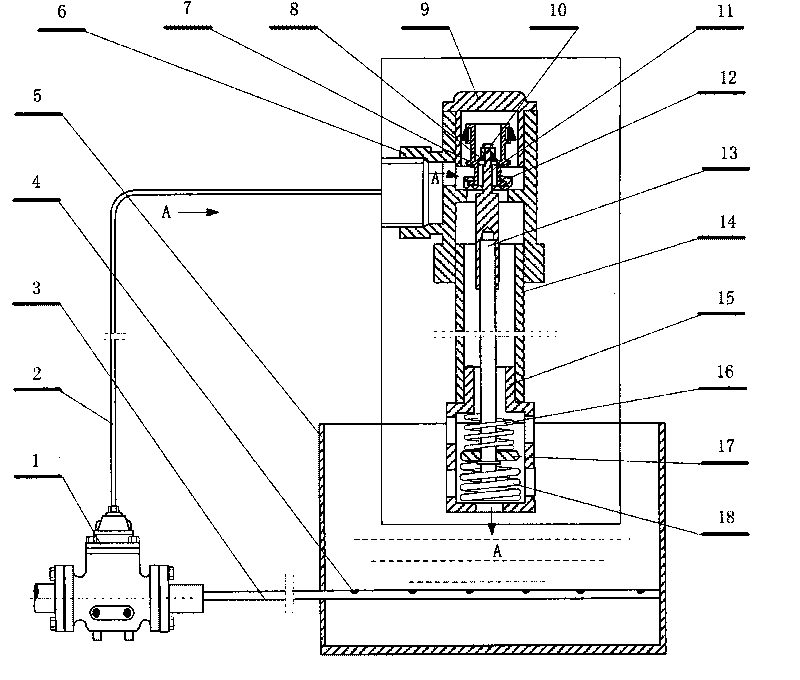

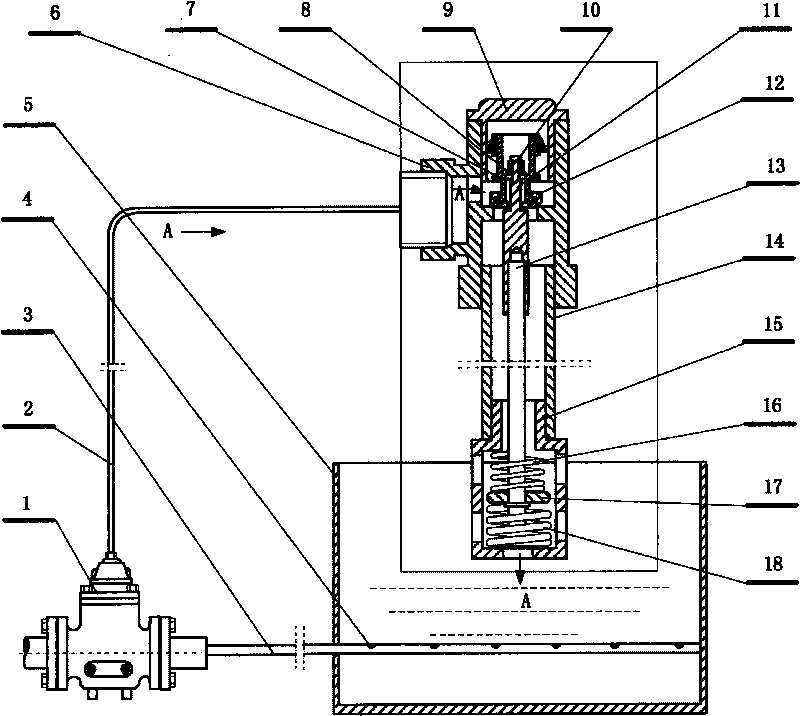

[0008] For the specific implementation manner of the present invention, see the working principle diagram of the system. The system is mainly composed of the main control valve (1), the main valve opening pipe (2), the main steam pipe (3), the steam distribution hole (4), the hot water pool (5), the temperature control pilot valve body (6), the large piston (7), seal ring (8), temperature control valve bonnet (9), small piston (10), upper linkage rod (11), large seal ring (12), lower linkage rod (13), connecting pipe (14), core cover (15), memory alloy (16), guide ring (17), back-moving spring (18) forms. The main control valve includes a diaphragm spool, a return spring on the upper end of the spool, a pressure relief control chamber connected to the control pipe of the temperature control pilot valve, a steam inlet connected to saturated steam, and a steam outlet connected to the main steam distribution pipe , the steam inlet is connected to the saturated steam pipe of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com