Boost pump

A technology of propulsion pump and pump casing, which is applied in ship propulsion, propulsion parts, ship parts, etc., can solve problems such as the reduction of effective power, and achieve the effect of improving thrust, simple structure and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

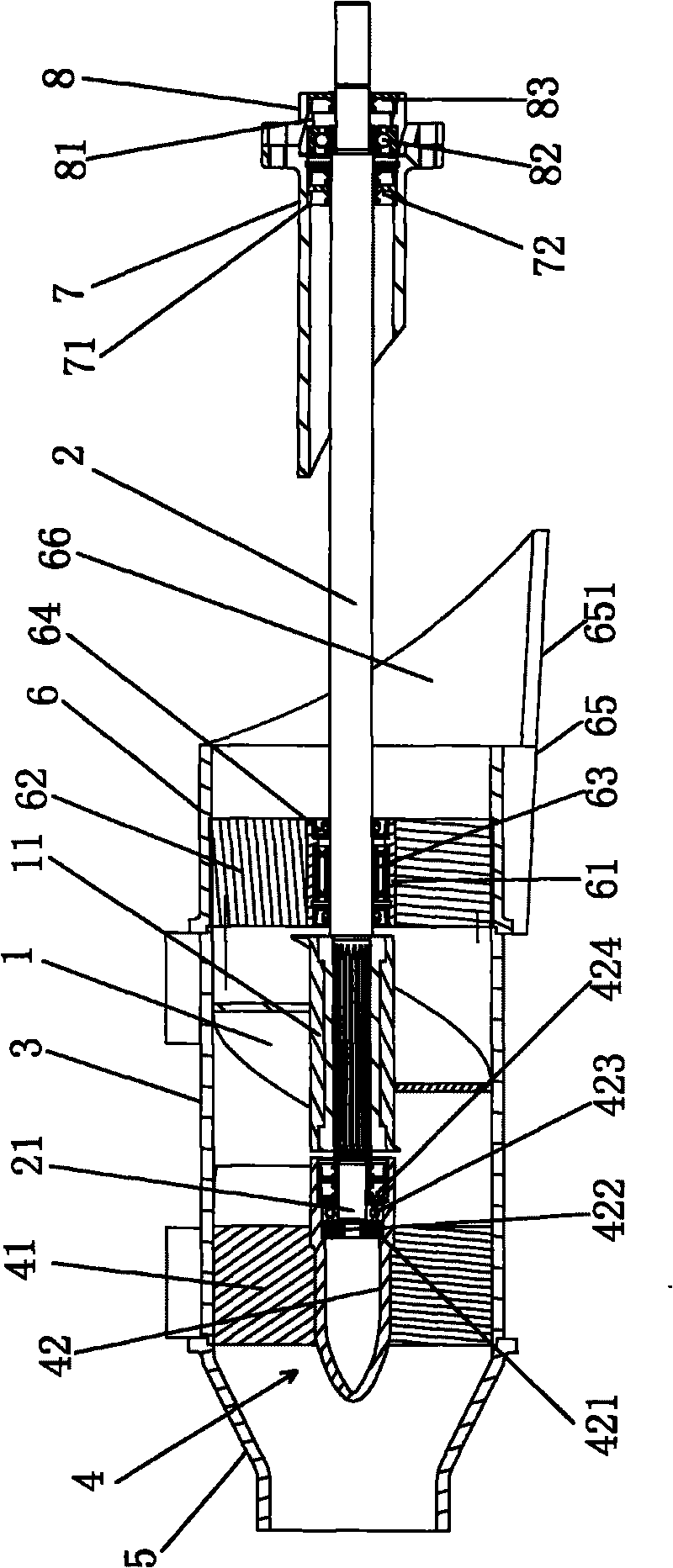

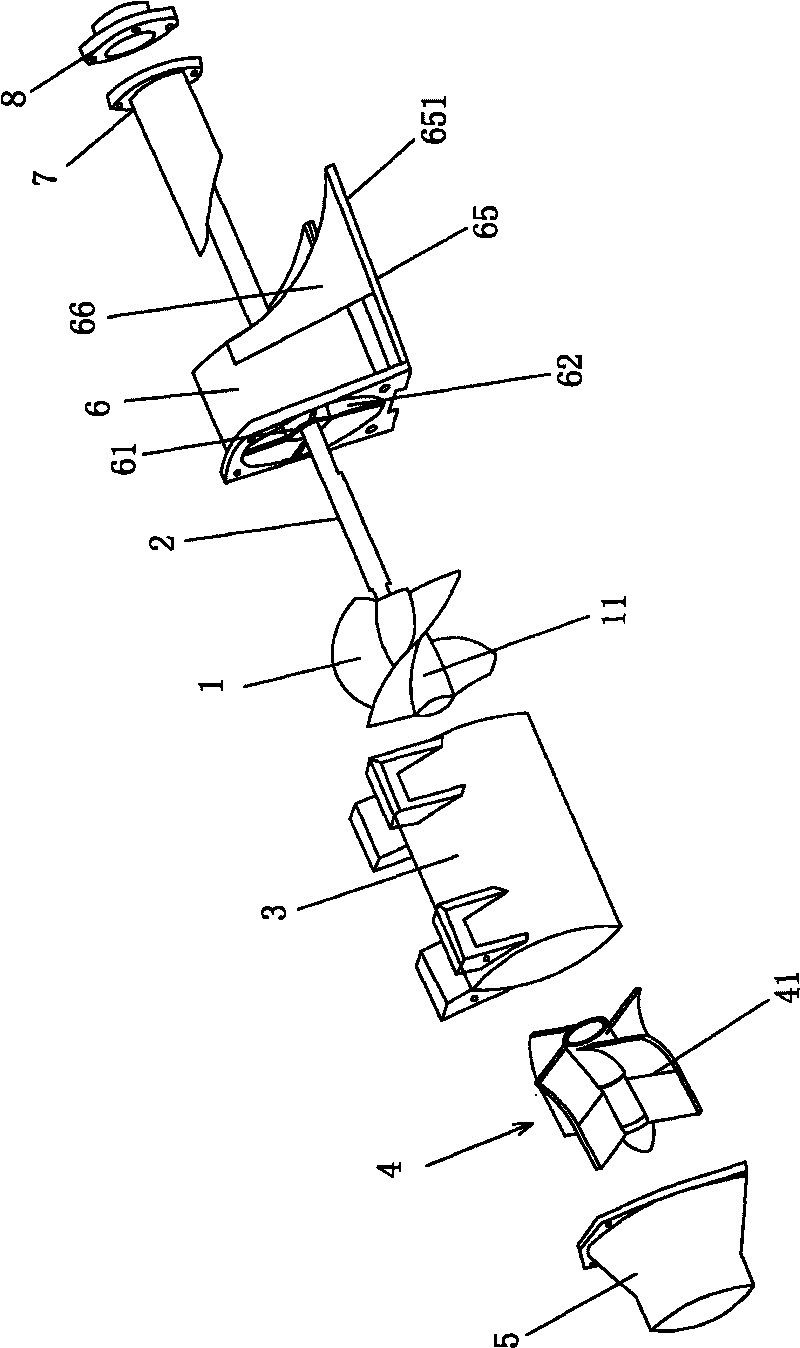

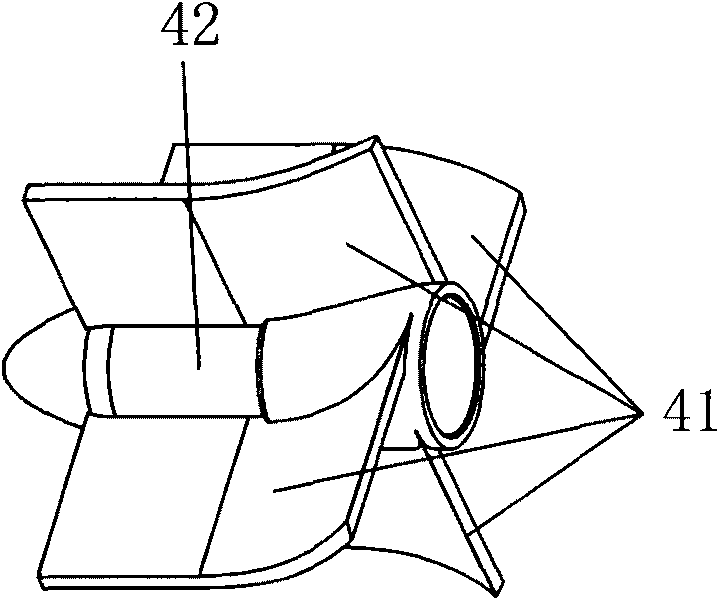

[0021] Embodiment: A propulsion pump, including a propeller 1 and a transmission shaft 2, the propeller is fixedly sleeved on the transmission shaft, based on the use direction of the propulsion pump, a deflector 4 is fixed inside the rear end of the pump casing 3, and the deflector mainly Consists of a number of guide vanes 41, the guide vanes are composed of a straight section 411 and an arc section 412, the straight section is parallel to the axial direction of the transmission shaft, one end of the arc section is connected with the straight section, and the other end of the arc section Close to the propeller, the straight section and the arc section are integrated, the guide vanes are at least two pieces, and several guide vanes are arranged at equal intervals around the central axis of the pump casing, and the end of the guide vanes away from the central axis of the pump casing is fixed in the pump casing surface, and the orientation of several guide vane arcuate segments ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com