High-altitude dismantling method of inside-climbing tower crane for towering structure construction

A technology for internal climbing towers and structures, applied to cranes and other directions, can solve problems such as heavy workload, high construction safety risks, and long construction period, and achieve the effects of improving work efficiency, improving stability and safety, and reducing demolition costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

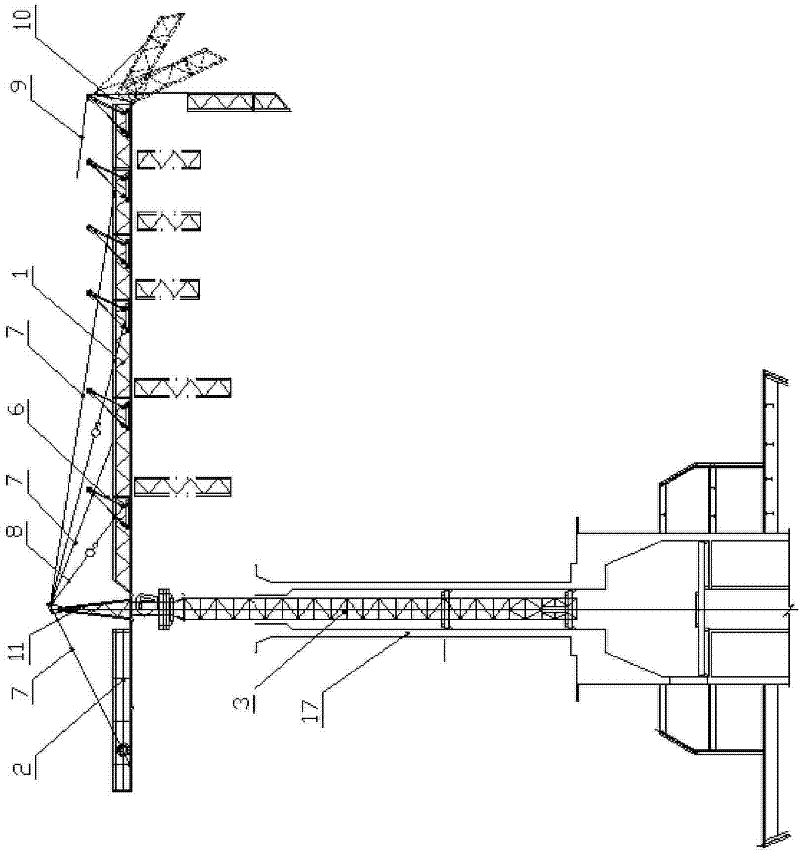

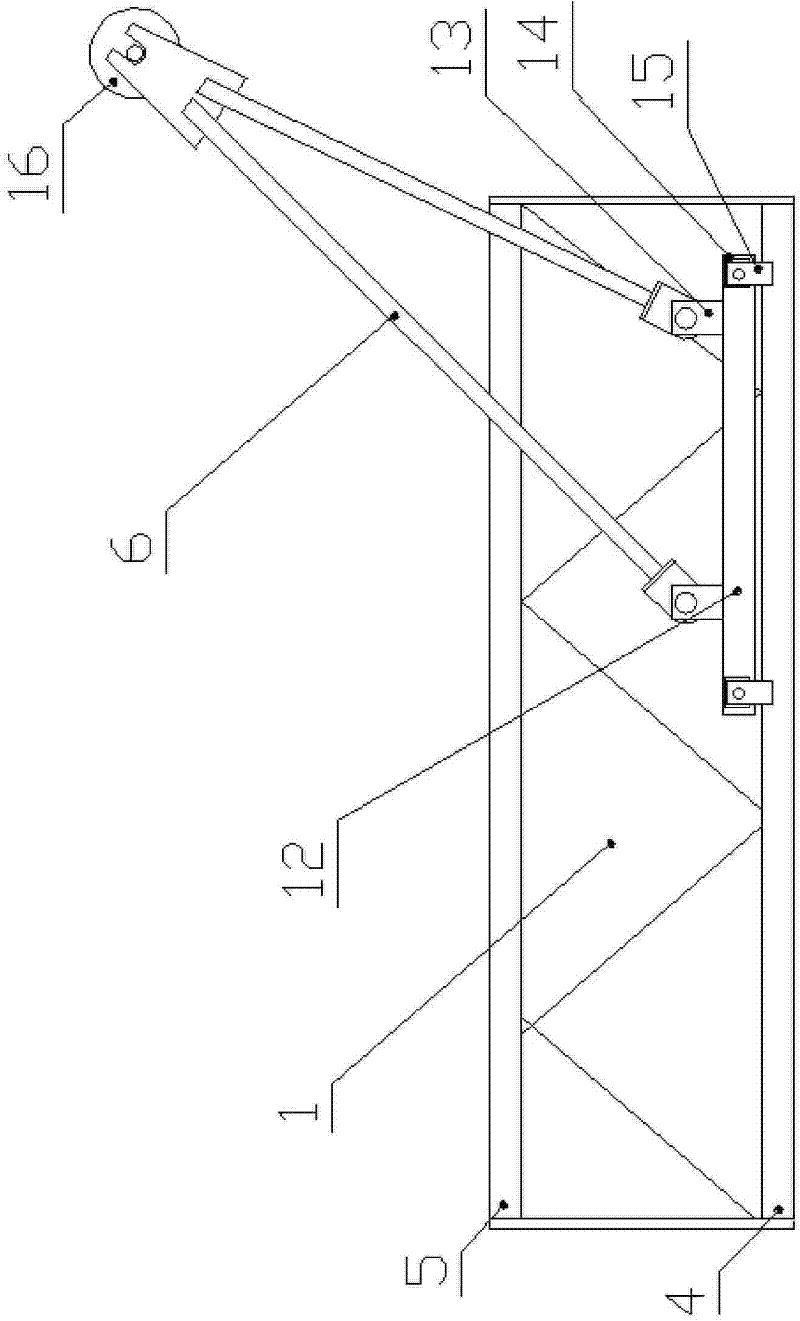

[0051] The removal process of the internal climbing tower crane with eight-section jib 1 and two-section balance jib 2 is as follows:

[0052] Remove the eighth and seventh boom booms at the outermost ends:

[0053] 1) First, move the luffing trolley 12 to the outer end of the sixth boom 1 (because the eighth boom 1 is short, move the eighth boom and the seventh boom 1 at the same time) dismantling), so that the lower ear plate 14 of the lifting luffing trolley 12 and the connecting plate 15 on the sixth boom 1 are connected and positioned through the pin shaft;

[0054] 2) Transform the control circuit of the lifting luffing trolley 12 so that the lifting luffing trolley 12 can only walk toward the inner end in one direction (to avoid safety accidents);

[0055] 3) Pass the hoisting rope 9 through the top guide pulley 16 of the pole mechanism, and fix the front end of the hoisting rope 9 at the joint between the eighth section and the seventh section boom 1;

[0056] 4) Sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com