Flame-retardant polypropylene material and preparation method

A flame retardant polypropylene and polypropylene technology, applied in the field of plastic materials, can solve the problems of unattainable, unimproved mechanical properties of flame retardant materials, and unsatisfactory mechanical properties of PP materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

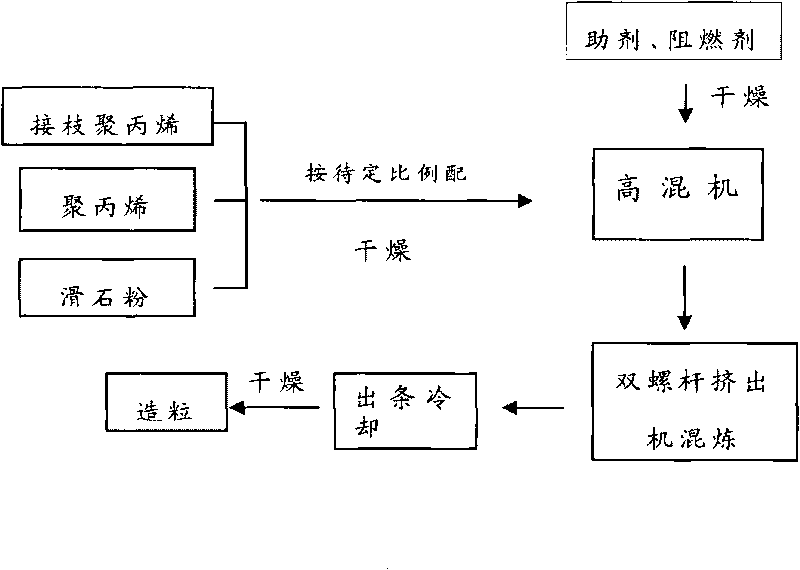

Method used

Image

Examples

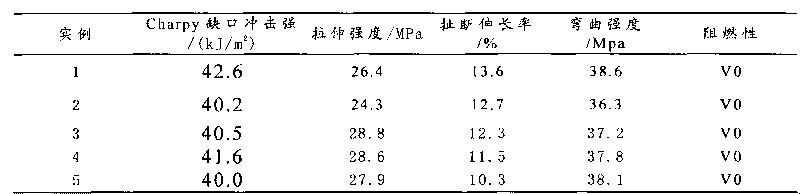

Embodiment 1

[0018] Implementation 1, unit: kg.

[0019] 65 parts of polypropylene particles, 0.2 parts of antioxidant 1010, 0.2 parts of antioxidant 168, 25 parts of halogen-free intumescent flame retardant, 4 parts of grafted polypropylene, 0.6 parts of calcium stearate, and 15 parts of talcum powder.

Embodiment 2

[0020] Implementation 2, unit: kg.

[0021] Polypropylene particle: 63 parts, 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168, 27 parts of halogen-free intumescent flame retardant, 4 parts of grafted polypropylene, 0.6 part of zinc stearate, 15 parts of talcum powder.

Embodiment 3

[0022] Implementation 3, unit: kg.

[0023] 61 parts of polypropylene particles, 0.2 parts of antioxidant 1010, 0.2 parts of antioxidant 168, 27 parts of halogen-free intumescent flame retardant, 6 parts of grafted polypropylene, 0.6 parts of calcium stearate, and 15 parts of talcum powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com