Method for preparing light-cumulating luminescent size

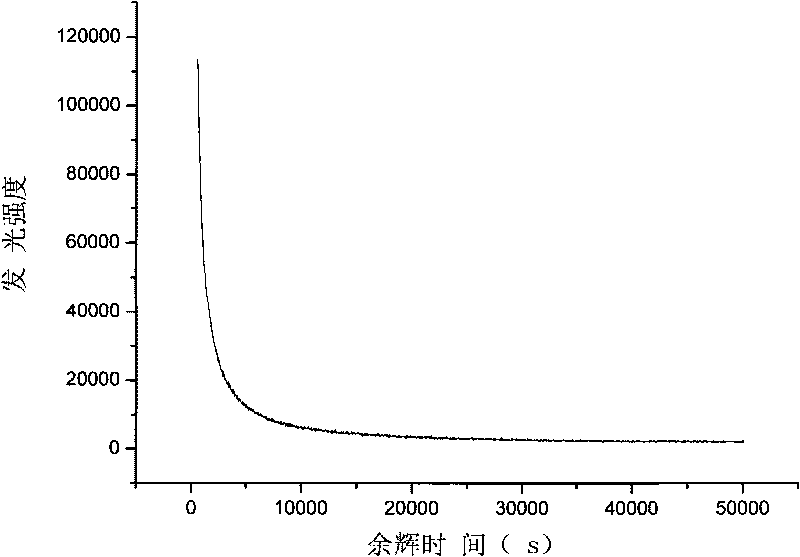

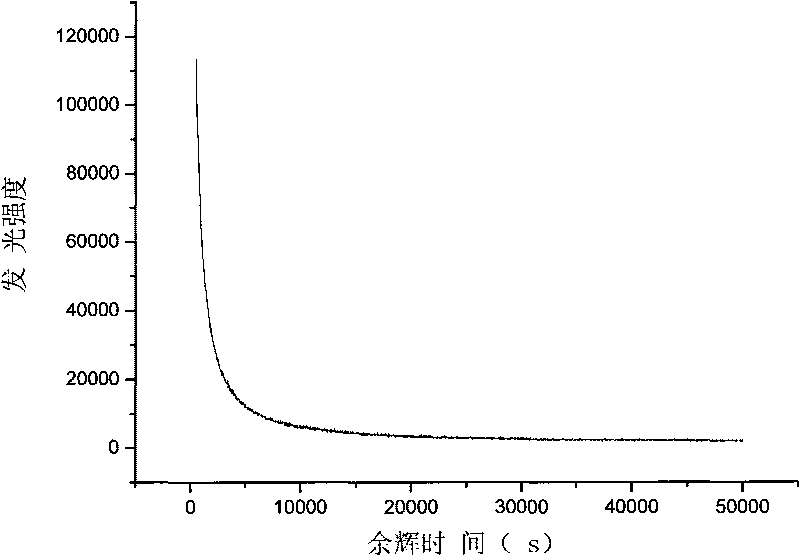

A light-storage type and slurry technology, which is applied in the field of preparation of light-storage type luminescent paste, can solve the problems of uneven agglomeration and dispersion of powder particles, low luminous efficiency, insufficient energy storage for long afterglow materials, etc., and achieves easy application. The effect of improving the performance and improving the luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Prepare the carrier: Dissolve the same amount of polyester resin 300 and polyester resin 630 (produced by Toyobo) in butyl cellosolve acetate to obtain carrier A, and equal amount of polyester resin 300 and polyester resin 630 with butyl cellosolve acetate Prepared according to the ratio of 1:2 in mass ratio; dissolve ternary vinyl acetate resin in butyl cellosolve acetate to obtain carrier B, prepare ternary vinyl acetate resin and butyl cellosolve acetate in a mass ratio of 1:4; dissolve During the process, all were heated to 80°C, stirred and dissolved; carrier A and carrier B were mixed at a mass ratio of 4:1 to prepare the required carrier C.

[0024] 2) Material mixing: aluminate green long-lasting luminescent material (SrAl 2 o 4 : Eu, Dy) and carrier C are fully mixed according to the mass ratio of 3:1, then add the dispersant polyethylene wax with a mass ratio of 10:1 to the mixture, and stir fully to make the concentration uniform.

[0025] 3) Slurry roll...

Embodiment 2

[0028] 1) Prepare the carrier: Dissolve an equal amount of polyester resin 300 and polyester resin 630 in dimethyl cellosolve to obtain carrier A, and equal amounts of polyester resin 300 and polyester resin 630 to dimethyl cellosolve in mass ratio Prepared in a ratio of 1:3; dissolving binary vinyl acetate resin in dimethyl cellosolve to obtain carrier B, and preparing binary vinyl acetate resin and dimethyl cellosolve in a mass ratio of 1:6; the dissolution process heated to 80°C, stirred and dissolved; carrier A and carrier B were mixed at a mass ratio of 3:1 to prepare the required carrier C.

[0029] 2) Material mixing; the sulfide red long-lasting luminescent material is CaS:Eu, Tm and carrier C are fully mixed in a mass ratio of 3:1, and then a dispersant stearic acid with a mass ratio of 20:1 is added to the mixture Zinc, stir well to make the concentration uniform.

[0030] 3) Slurry rolling: fully roll the mixed slurry on a three-roll machine to obtain a slurry with...

Embodiment 3

[0032] 1) Prepare carrier: Dissolve equal amounts of polyester resin 300 and 630 in butyl cellosolve acetate to obtain carrier A, and prepare equal amounts of polyester resin 300 and 630 and butyl cellosolve acetate in a mass ratio of 1:4; Ternary vinyl acetate resin is dissolved in butyl cellosolve acetate to obtain carrier B, and the three-component vinyl acetate resin and butyl cellosolve acetate are prepared in a mass ratio of 1:8; during the dissolution process, they are all heated to 70°C and stirred to dissolve; Carrier A and carrier B are mixed at a mass ratio of 2:1 to prepare the desired carrier C.

[0033] 2) Material mixing: the aluminate blue long afterglow luminescent material is CaAl 2 o 4 : Eu, Dy and carrier C are fully mixed according to the mass ratio of 2.5:1, then add the dispersant microcrystalline paraffin with the mass ratio of the mixture being 15:1, and fully stir to make the concentration uniform.

[0034] 3) Slurry rolling: fully roll the mixed sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com