Construction method for pushing and furling complete bracket of steel box girders

A construction method and steel box girder technology, applied in bridges, bridge forms, bridge construction, etc., can solve problems such as steel box girders that cannot overcome atmospheric temperature changes, violent collisions of closing sections, and affecting construction progress, so as to save mechanical materials, The effect of improving precision and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

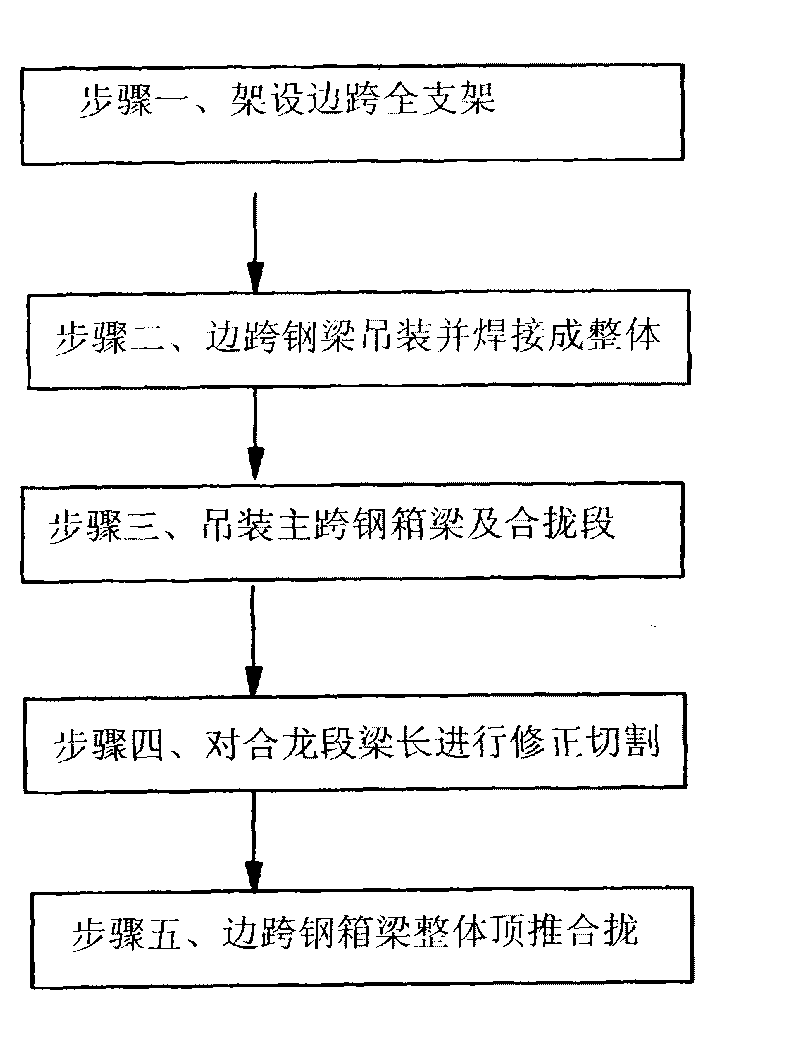

[0040] see figure 1As shown, a kind of side-span steel box girder full support push-up construction method provided by the present invention comprises the following steps:

[0041] Step 1: Erect the side-span full support

[0042] Step 2: Hoisting and welding side-span steel box girders

[0043] Step 3: Hoisting the steel box girder of the main span and the steel box girder of the closing section

[0044] Step 4: Carry out the second corrective cutting of the beam length of the closing section

[0045] Step 5: Push and close the side span as a whole

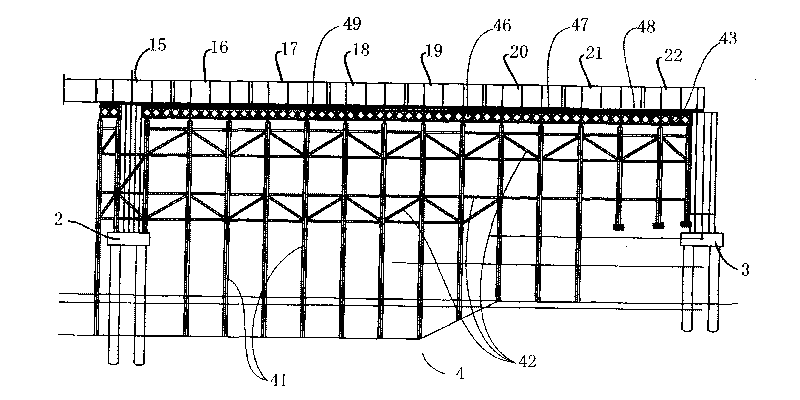

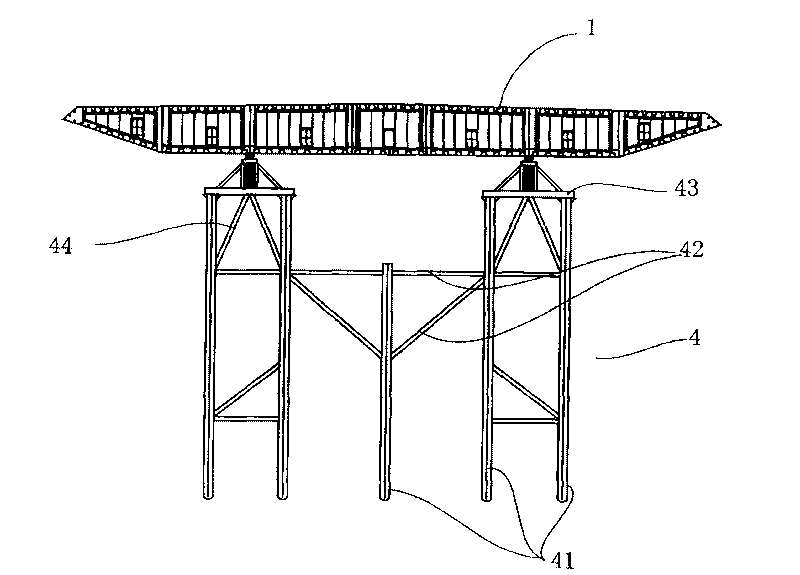

[0046] For the sake of illustration, please combine figure 2 As shown, eight side-span steel box girders erected on No. A pier 2 to No. B pier 3 are closed with the main span as an example to describe the construction method of the present invention in detail. Among them, No. B Pier 3 is located on the bank, and No. A Pier 2 is located in the middle of the river near the closed section. The eight side-span steel box girders...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com