Design method for high reliability of turbonator and evaluation method thereof

A technology of a turbo-generator and an evaluation method, which is applied to mechanical equipment, machines/engines, etc., can solve the problems of not being able to give the forced outage rate of the turbo-generator, and unable to determine the forced outage rate of the turbo-generator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

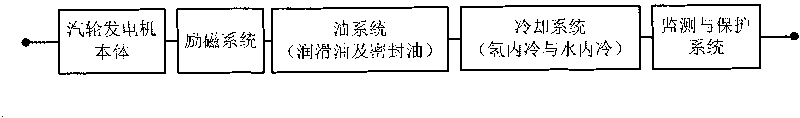

[0047] Such as figure 1 Shown is the reliability block diagram of the turbo-generator system. A certain type of 600MW turbo-generator adopts a brushless excitation system without auxiliary exciter. Oil), cooling system (hydrogen internal cooling and water internal cooling), monitoring and protection system, its reliability block diagram is as follows figure 1 Show.

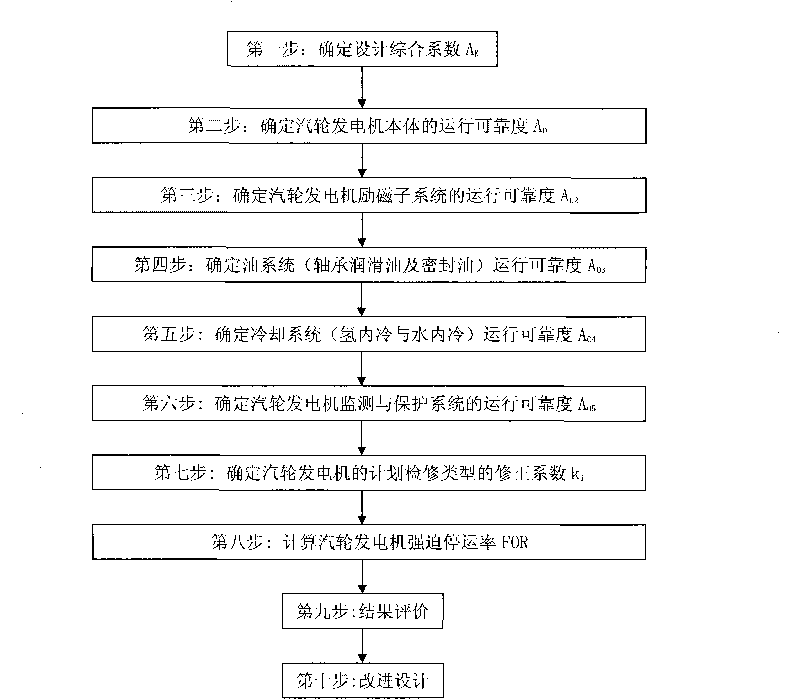

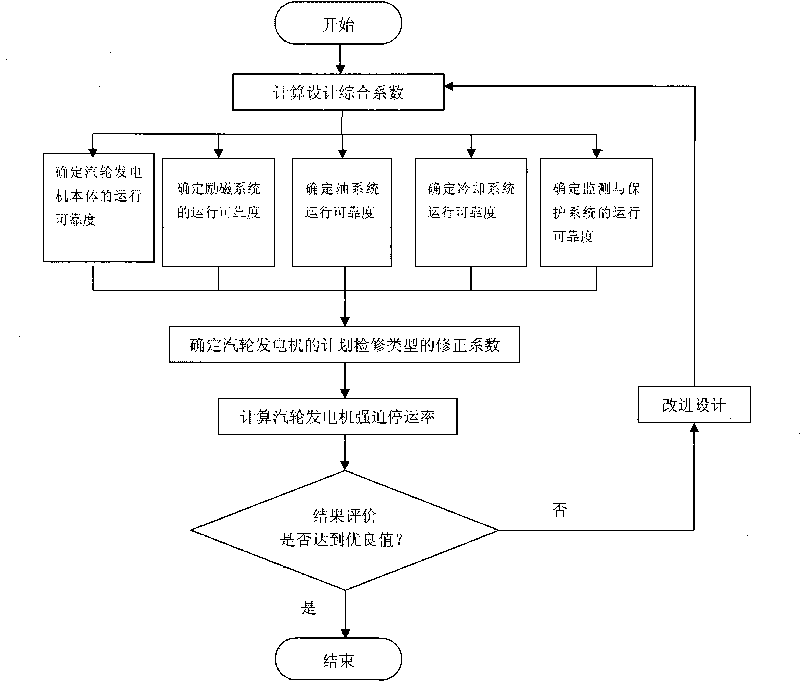

[0048] Such as figure 2 Shown, be the flow chart of the method adopted in the present invention, the design method of high reliability of steam turbine generator and evaluation method thereof are:

[0049]The strength design of this type of 600MW turbogenerator is all qualified, calculated from Table 1, K 1 = 0; the rotor vibration design is qualified, the stator vibration design and the fan vibration design are not carried out, and K is calculated by looking up Table 2 2 =0+0.0006+0.0006=0.0012; no life design is carried out, calculated from table 3, K 3 =0.0006+0.0006+0.0006=0.0018. Considering the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com