Steam compressor arrangement

A vapor compression and compressor technology, which is applied in steam engine devices, components of pumping devices for elastic fluids, and steam applications, etc., can solve problems such as ineffective utilization and increase in compressor temperature, and achieve effective energy and efficient utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

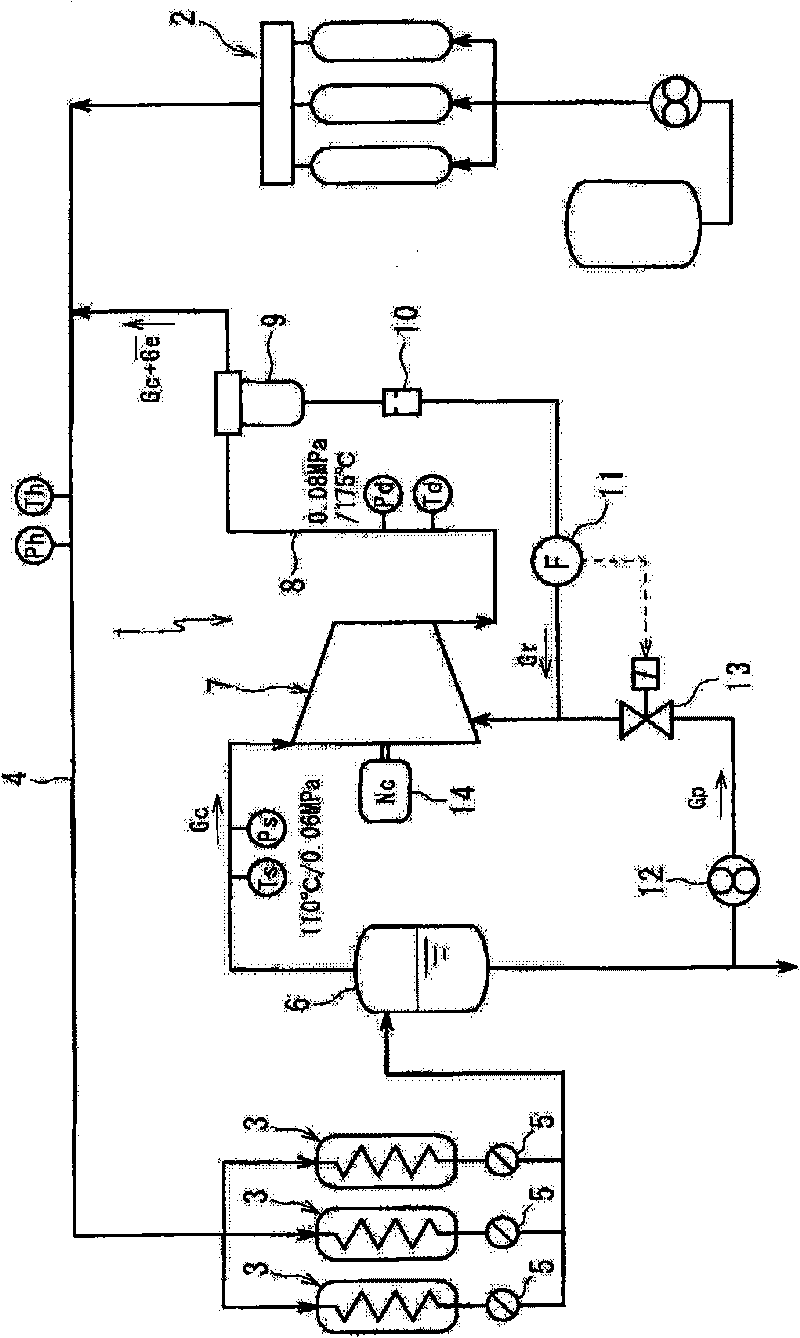

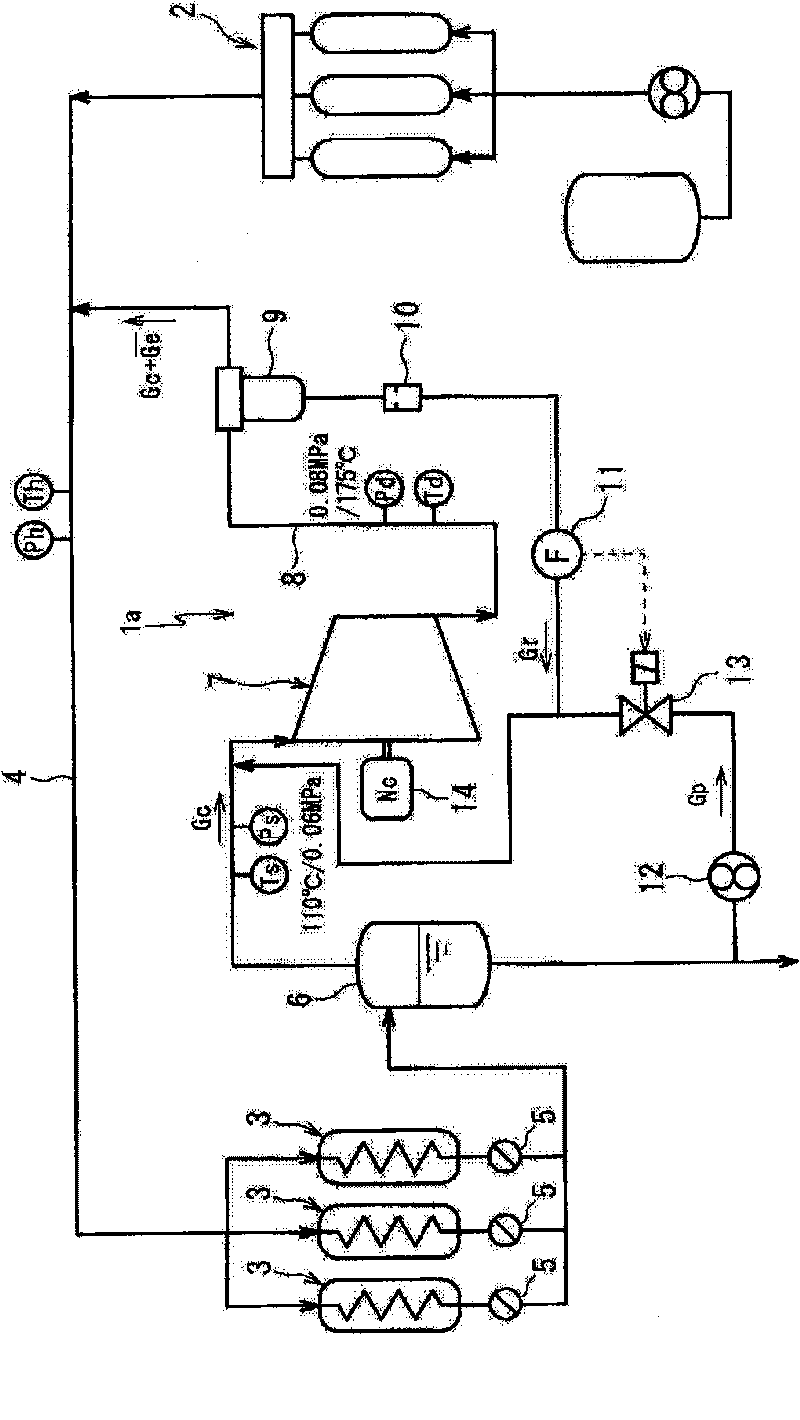

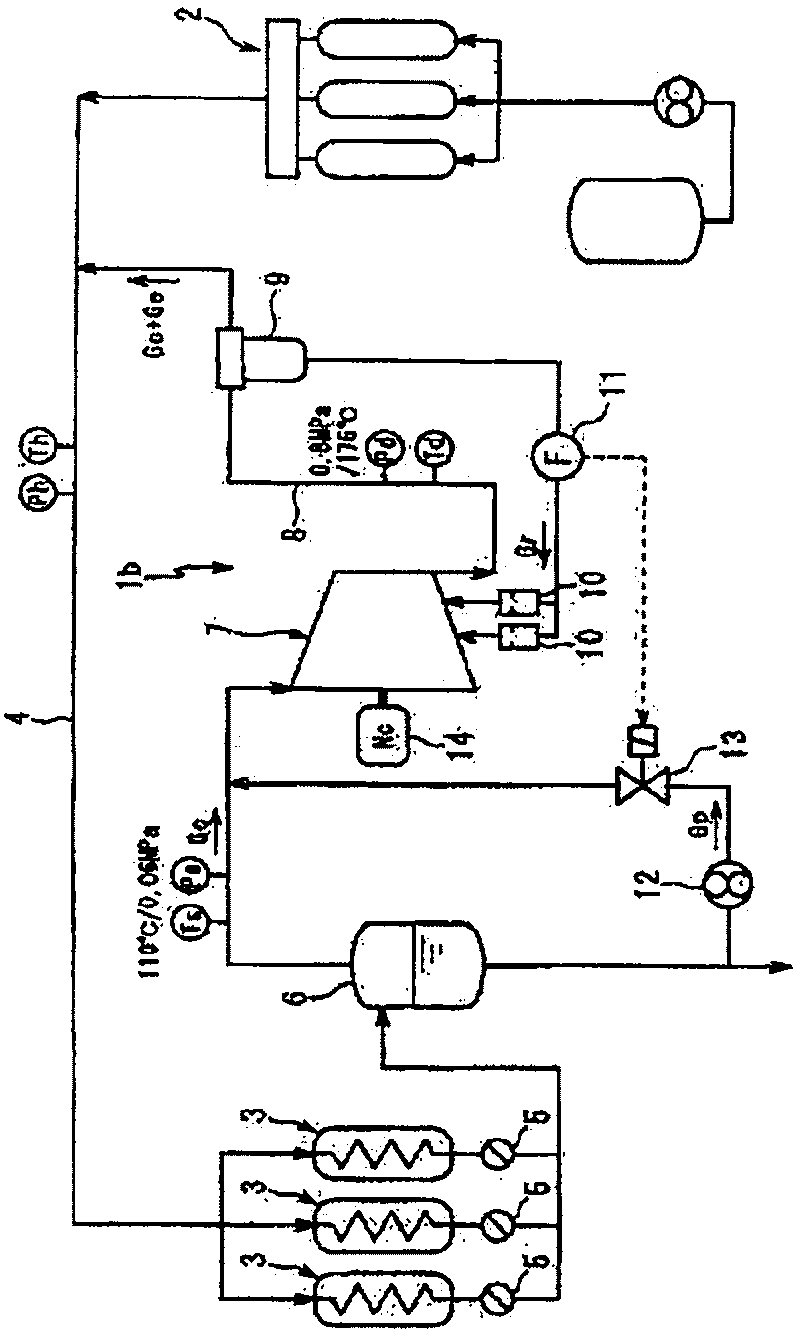

[0018] Embodiments of the present invention will be described below with reference to the drawings. figure 1 The configuration of the manufacturing equipment including the vapor compression device 1 according to the first embodiment of the present invention is shown.

[0019] The vapor compression device 1 is a device that supplies vapor (gas-phase object fluid) at a predetermined supply pressure Ph (for example, 0.8 MPaG) from a boiler 2 to a required facility (manufacturing facility) 3 through a main pipe 4, wherein the suction temperature Ts (for example, 110°C) and low-pressure steam with a mass flow Gc (for example, 1000kg / h) are sucked into the action space of the screw compressor 7 (that is, between a pair of internal and external screw rotors meshing with each other and the housing that accommodates the screw rotors) The space formed between. This space is not directly connected with the suction part and the discharge port of the screw compressor 7), and the pressure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com