Zero maintaining mechanism of 2D digital servo valve

A technology of holding mechanism and digital servo, which is applied in the direction of servo motor components, mechanical equipment, fluid pressure actuators, etc., can solve problems such as difficult to ensure zero position stability, and achieve simple structure, convenient manual mechanical zero adjustment, and small moment of inertia Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

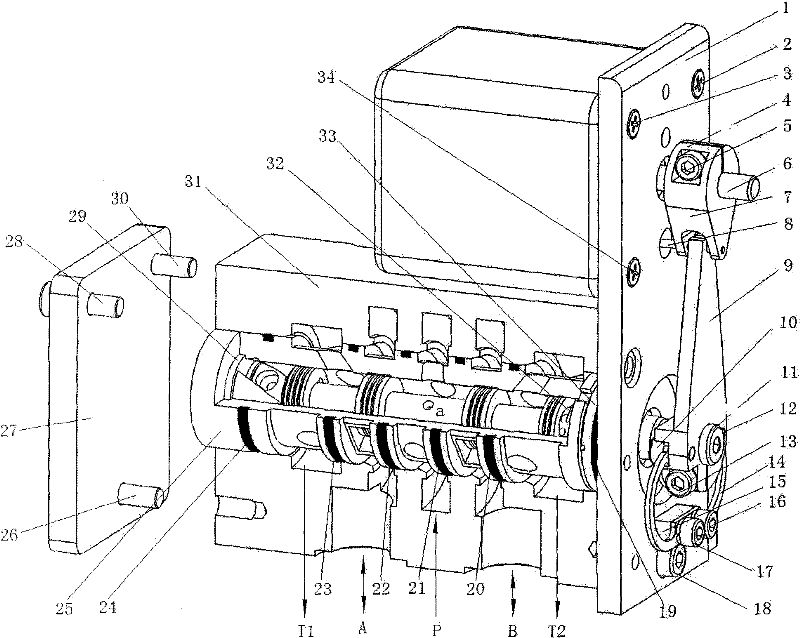

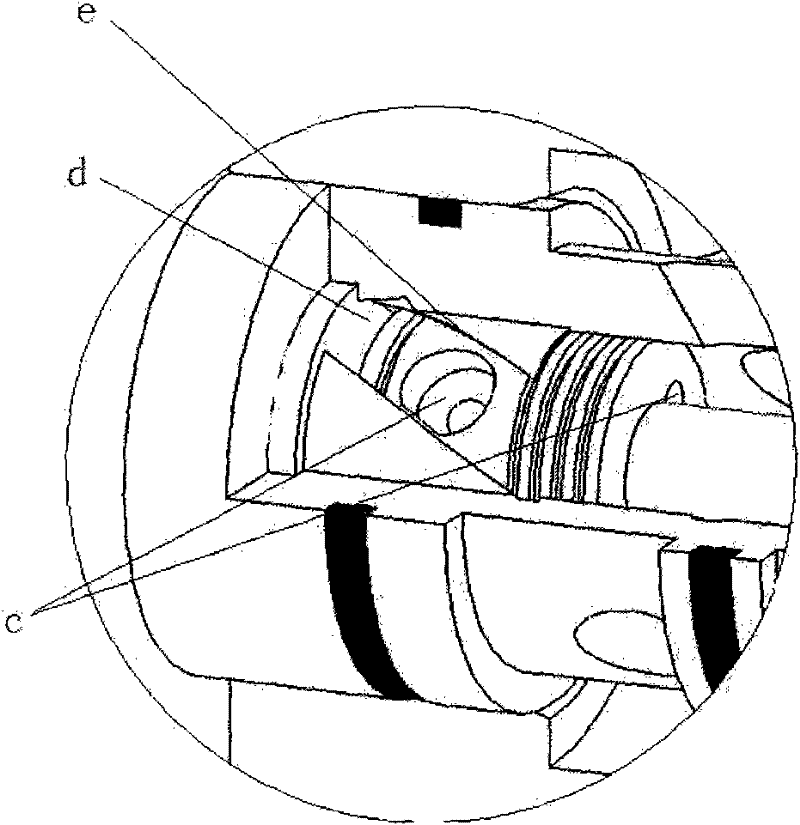

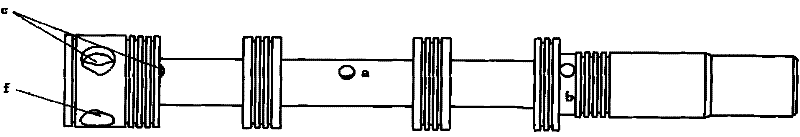

[0021] refer to Figure 1 ~ Figure 4 , a zero-position holding mechanism for a 2D digital servo valve, comprising an upper balance wheel 4 connected to a motor shaft, a lower balance wheel 9 connected to a spool, a swing shaft 8 and a zero-position holding spring 14, the middle of the upper balance wheel 4 There is a mounting hole through which the shaft of the power supply passes. The upper end of the upper balance wheel 4 is cut with a through groove. The two halves of the upper end of the upper balance wheel 4 are fixedly connected, and the lower end of the upper balance wheel 4 has a notch. , the swing shaft 8 is installed in the notch, and one end of the swing shaft 8 extends into the limit hole of the motor mounting plate, and the upper part of the lower balance wheel 9 is rotatably sleeved on the swing shaft 8, and the lower balance wheel The lower part of 9 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com