Modularized combination type heat insulating method

A combined and modular technology, applied in thermal insulation, pipeline protection, pipeline protection through thermal insulation, etc., can solve problems such as difficulties in thermal insulation construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

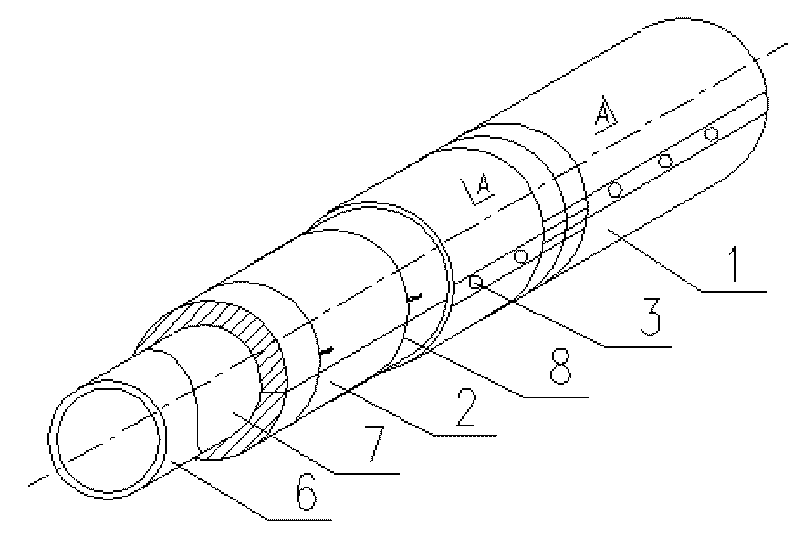

[0018] The modular combined heat preservation method at least includes a heat preservation equipment main body, an outer protective layer 1 and a heat preservation layer 2, and the heat preservation equipment main body is divided into a dynamic heat preservation main body and a static heat preservation main body.

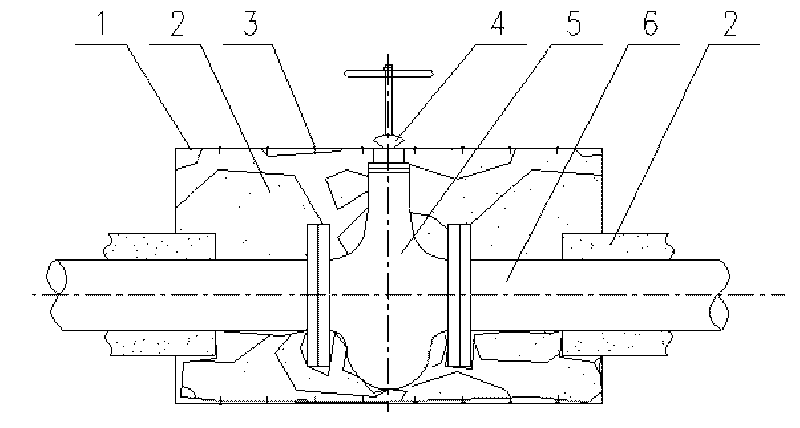

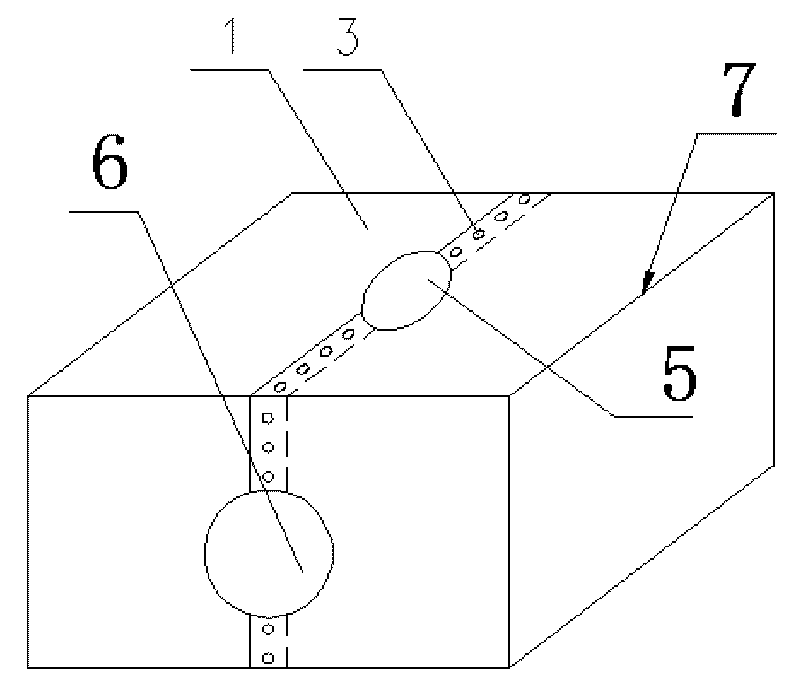

[0019] like figure 1 combine figure 2 Shown: Smaller valves or other special-shaped parts are called dynamic thermal insulation main bodies, which are composed of two outer protective layers 1 connected outside the dynamic thermal insulation main body, and adopt a square box thermal insulation structure. There is an insulating layer 2 between the two outer protective layers 1, and inside the insulating layer 2 is a dynamic insulating body such as a valve or other special-shaped parts. Use self-tapping screws 3 to fix the two halves of the insulation shell filled with the insulation layer 2 on the valve body or other special-shaped parts. The pipeline 6 on the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com