Automatic switching cylinder manifold device

An automatic switching and busbar technology, applied in the container discharge method, container filling method, pipeline system, etc., can solve the problems of insensitive switching, unstable output gas, and impure output gas, so as to reduce the intensity of manual operation , Stable gas output, sensitive switching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

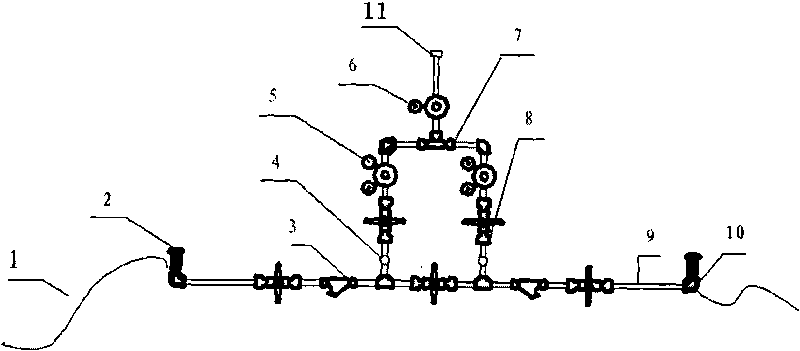

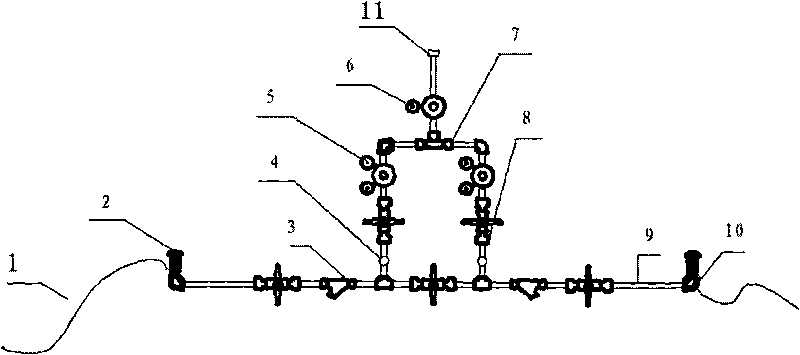

[0012] The structure of this embodiment is as figure 1 As shown, an automatic switching busbar device, its main structure is composed of air intake and air outlet, the air inlet end is connected to the external air source through a high-pressure hose 1, the air outlet end is connected to the pipeline interface 11 through a shuttle valve switching valve 7, and The connection between the high-pressure hose 1 and the shuttle valve switching valve 7 is connected through a high-pressure pipeline 9, and the high-pressure hose 1 and the high-pressure pipeline 9 are arranged in double sets on both sides of the shuttle valve switching valve 7. Safety, the high-pressure hose 1 communicates with the high-pressure pipeline 9 through the pipeline angle valve 2, tee and elbow 10, and the high-pressure pipeline 9 is also equipped with a filter 3 and a first-stage decompression before connecting with the shuttle valve switching valve 7 device 5, and high-pressure cut-off valve 8, and the inst...

Embodiment 2

[0014] It is the same as the automatic switching busbar device of Embodiment 1, the difference is that: between the above-mentioned filter 3 and the second high-pressure cut-off valve 8, an alarm device interface 4 is also installed, and an alarm device is reserved here. The device interface can realize real-time monitoring of remote pressure, gas quality, temperature, bottle change and other work requirements.

Embodiment 3

[0016] The same as the automatic switching busbar device in Embodiment 1, the difference is that a secondary pressure reducer 6 is installed between the above-mentioned shuttle valve switching valve 7 and the pipeline interface 11 to make the output gas more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com