A method for controlling the distribution of Fischer-Tropsch reaction products with CO-based catalysts

A Fischer-Tropsch reaction and catalyst technology, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of improving product separation and purification and catalyst recovery process difficulty, and achieve corresponding sensitive and efficient product switching. The effect of stable catalyst performance and high olefin selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 0.74g Co(NO 3 ) 2 ·6H 2 O, 0.04mL mass fraction is 50% Mn(NO 3 ) 3 4H 2 O aqueous solution, 0.05gZr(NO 3 ) 4 ·5H 2 O, 0.015g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 20mL of water and stirred evenly to make a mixed solution. Weigh 0.85gSiO2 2 Carrier, mix the mixture with the carrier evenly, impregnate in vacuum at room temperature for 5 hours, separate solid and liquid, wash with water, and dry at 100°C for 12 hours to obtain a solid powder; mix the obtained solid powder with 0.5g of phenylalanine, and the mixed powder is heated at 500°C Calcined for 5 hours, ground, pressed into tablets, and sieved to obtain 15%Co-1%Mn-1%Zr-0.5%Ce-0.05%N-0.1%C / SiO 2 catalyst.

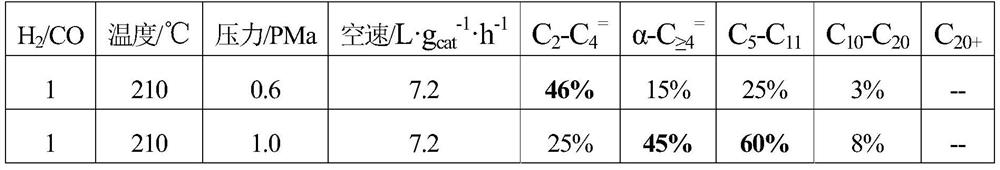

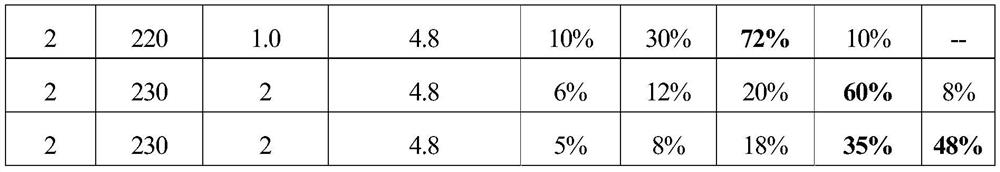

[0020] 0.5g 15%Co-1%Mn-1%Zr-0.5%Ce-0.05%N-0.1%C / SiO 2 The catalyst is mixed with an equal volume of quartz sand, placed in a fixed-bed reactor, and pure H 2 Gas (H 2 =99.9%), heated up to 450°C at a rate of 5°C / min, maintained for 5h, then cooled to 180°C, fed into synthesis gas, and carried out the...

Embodiment 2

[0024] 0.50g Co 2 (CO) 8 , 0.09g Mn(Ac) 2 , 0.047g Zr(NO 3 ) 3 ·6H 2 O, 0.03g Ce(NO 3 )3 ·6H 2 O was dissolved in 20mL of ethanol and stirred evenly to make a mixed solution. Weigh 1.0g SiO2 2 Carrier, mix the mixed solution with the carrier evenly, impregnate in vacuum at room temperature for 5 hours, separate solid and liquid, wash with water, and dry at 100°C for 12 hours to obtain a solid powder; mix the obtained solid powder with 1.0g of phenylalanine, and the mixed powder is heated at 500°C Roast for 5h, grind, press into tablets, and sieve to get 20%Co-2%Mn-1%Zr-1%Ce-0.1%N-0.1%C / SiO 2 catalyst.

[0025] 0.5g 20%Co-2%Mn-1%Zr-1%Ce-0.1%N-0.1%C / SiO 2 The catalyst is mixed with an equal volume of quartz sand, placed in a fixed-bed reactor, and pure H 2 Gas (H 2 =99.9%), heated up to 450°C at a rate of 5°C / min, maintained for 5h, then cooled to 180°C, fed into synthesis gas, and carried out the Fischer-Tropsch reaction of synthesis gas to hydrocarbon products acco...

Embodiment 3

[0029] 0.50g Co(NO 3 ) 2 ·6H 2 O, 0.02mL 50% Mn(NO 3 ) 3 4H 2 O, 0.10g Zr(NO 3 ) 4 ·5H 2 O, 0.031g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 20mL of water and stirred evenly to make a mixed solution. Weigh 1.0g Al 2 o 3 Carrier, mix the mixed liquid with the carrier evenly, impregnate in vacuum at room temperature for 5 hours, separate solid and liquid, wash with water, and dry at 100°C for 5 hours to obtain a solid powder; mix the obtained solid powder with 0.5g melamine, and roast the mixed powder at 500°C for 5 hours, Grinding, tableting, and sieving to obtain 10%Co-0.5%Mn-2%Zr-1%Ce-0.08%N-0.05%C / Al 2 o 3 catalyst.

[0030] 0.5g 10%Co-0.5%Mn-2%Zr-1%Ce-0.08%N-0.05%C / Al 2 o 3 The catalyst is mixed with an equal volume of quartz sand, placed in a fixed-bed reactor, and pure H 2 Gas (H 2 =99.9%), heated up to 450°C at a rate of 5°C / min, maintained for 5h, then cooled to 180°C, fed into synthesis gas, and carried out the Fischer-Tropsch reaction of synthesis gas to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com