Method for manufacturing integrated packaged high-power LED illuminating light source, and LED illuminating lamp

A LED lighting, LED lighting technology, applied in light source, electric light source, point light source, etc., can solve the problems of light source glare and light pollution, large chemical radiation, unnatural light, etc., achieve soft light, high color rendering, The effect of convenient transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

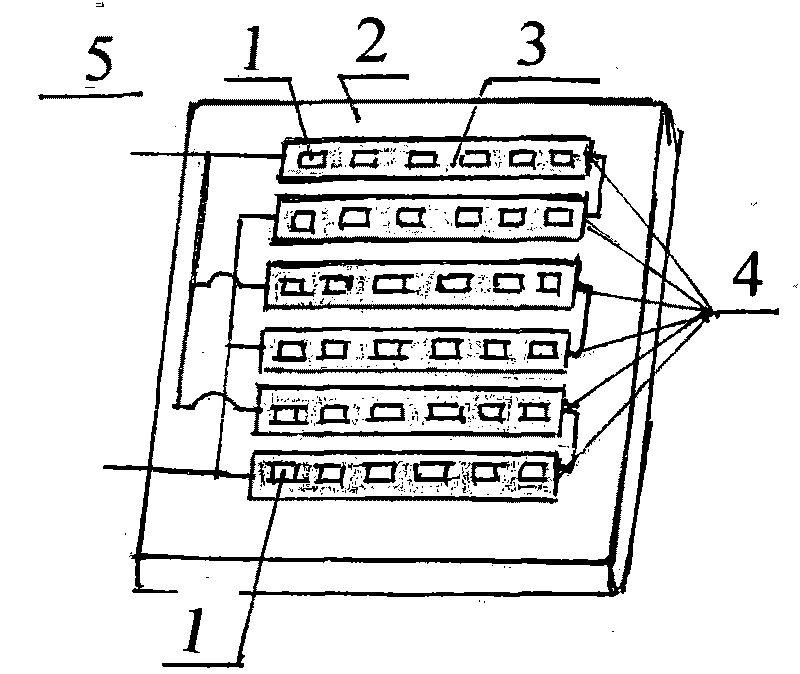

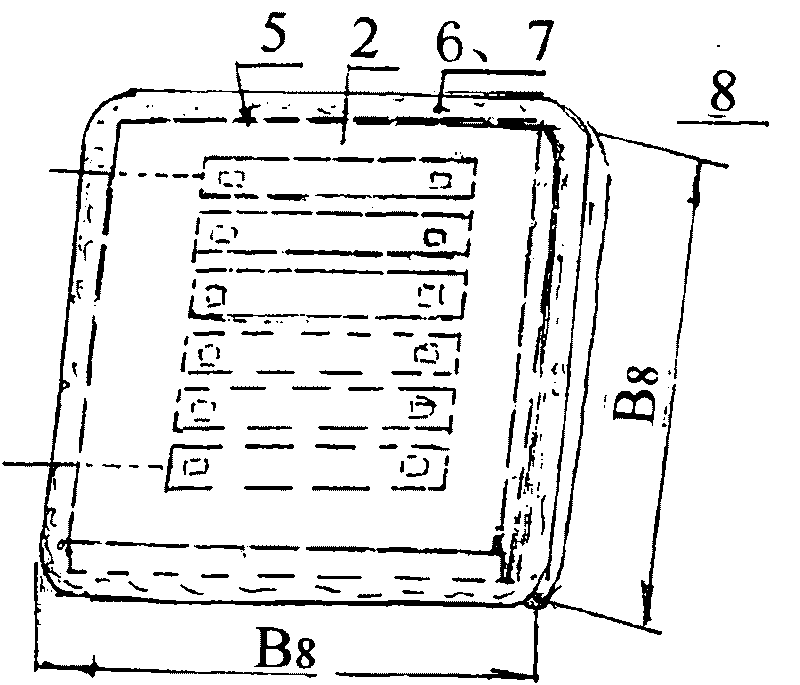

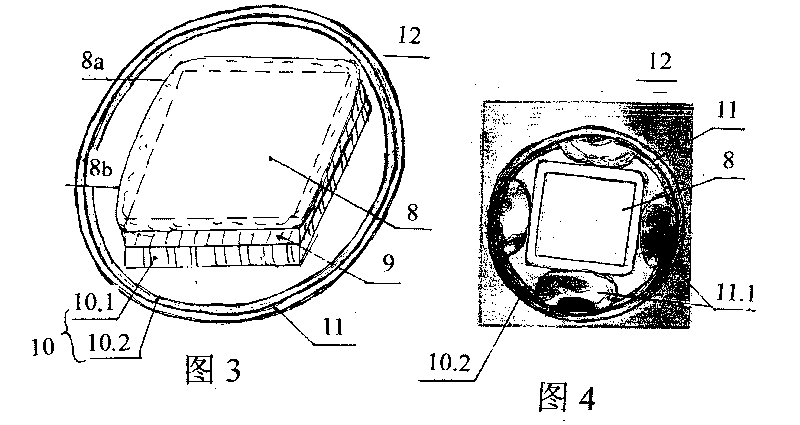

[0014] Example: see Figure 1-Figure 5 ,

[0015] This embodiment integrates a manufacturing method of encapsulating a high-power LED lighting source, and the LED lighting source is used for a high-power street lamp. The preparation method comprises the following steps:

[0016] 1) see figure 1 , select six single white LED chips 1 belonging to semiconductor elements, put them on the substrate 2 made of organic materials according to a certain distance, and use conductive gel silver glue 3 to bond and fix the six single white LED chips to form a light emitting chip 4 ; The power of a single white LED chip 1 is 0.01-3 watts (can be purchased in companies specializing in the production of semiconductor-LED chips in the world). 2) see figure 1 (For example), six light-emitting chips 4 are connected in series (two in series) and parallel (three in parallel) to achieve the light source chip 5 with a required power of 90 watts. 3) see figure 2 1. The light source chip 5 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com