Refrigerant recovery control device and use method thereof

A control device and refrigerant recovery technology, which is applied in the direction of measuring devices, refrigerators, refrigeration components, etc., can solve the problems of increasing operation steps, errors, affecting efficiency, etc., and achieve the effects of overcoming difficult control, safe operation, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

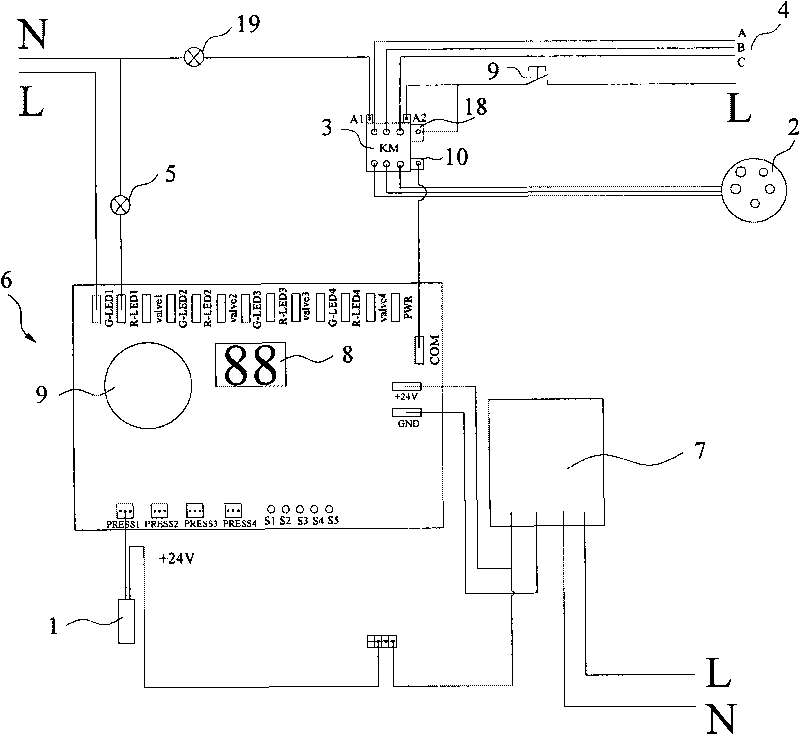

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the following only describes the features of the present invention that are different from the prior art, and the technical features that can be found in the prior art will not be repeated here.

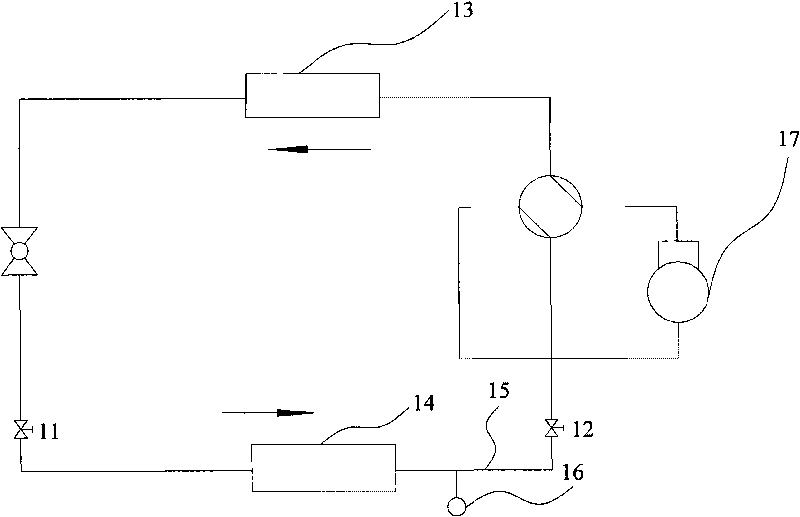

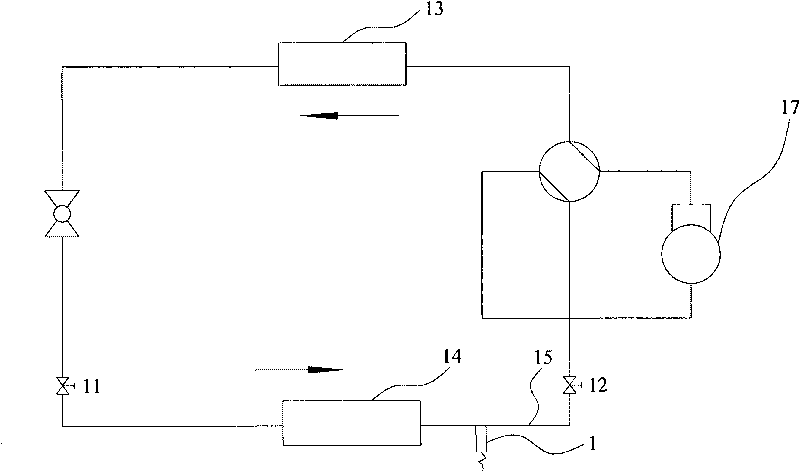

[0024] For easy understanding, first introduce the principle and operation of refrigerant recovery, refer to figure 2 , shows the principle diagram of the refrigerant recovery system according to the present invention. In the production of air-conditioning outdoor units, the connection test of the internal and external units is required in the test process. After the test is completed, the refrigerant in the common indoor unit needs to be recovered to the external unit condenser 13 of the product. Close the small valve 11 of the high-pressure pipe of the external unit. At this time, the refrigerant cannot be dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com