Control method for pressure balance of heat pump air conditioner

A technology of balance control and heat pump air-conditioning, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of increased reliability risks and increased costs of the air-conditioning system space, to improve frequent start-up performance and reliability, reduce The effect of starting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

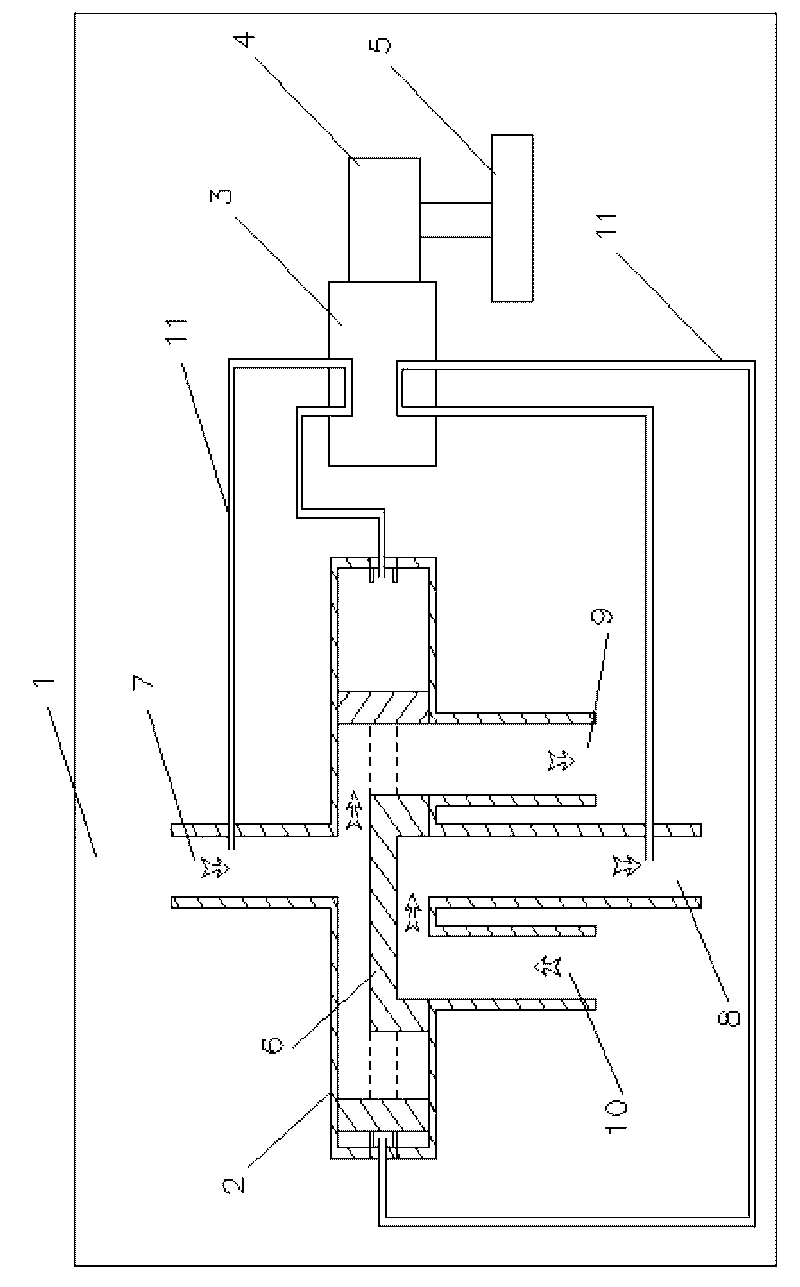

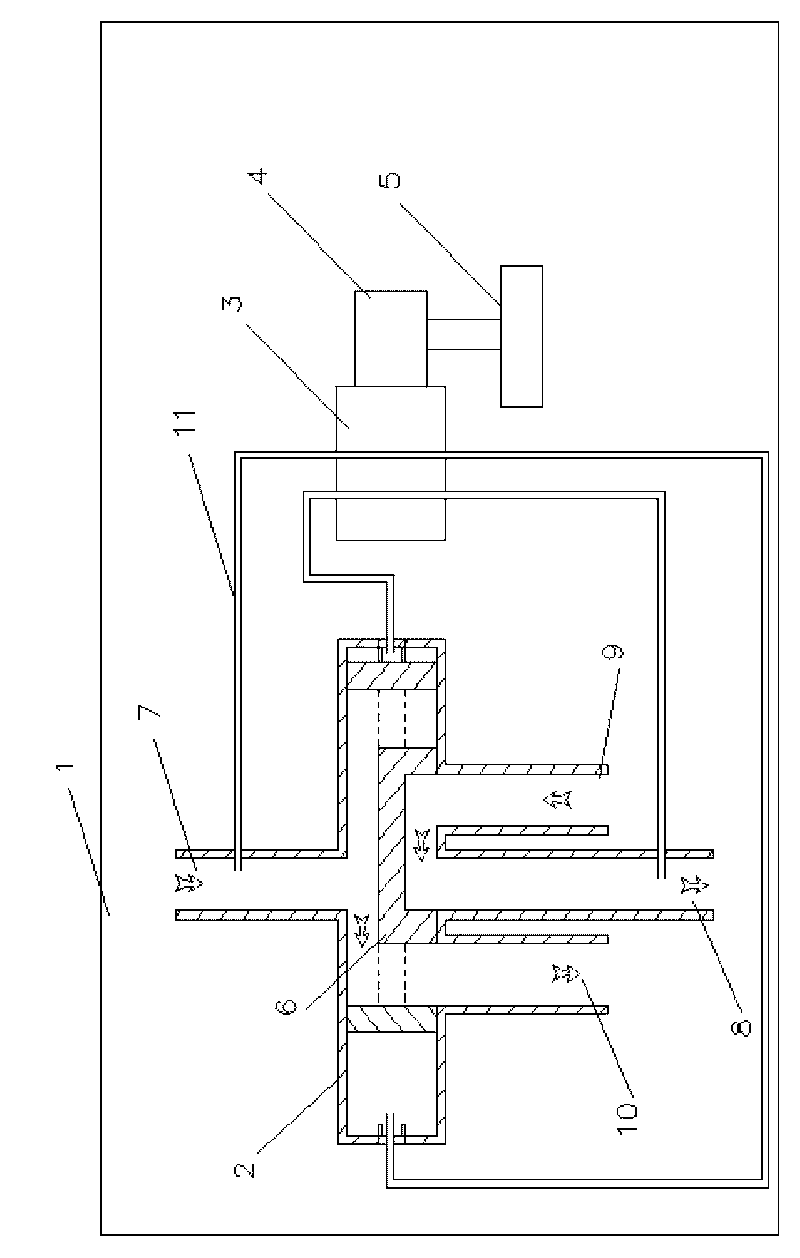

Embodiment 1

[0028] When the compressor works during the refrigeration process, the controller 5 turns off the coil 4. At this time, the slider 6 is located at the left end of the main valve body 2, and the first refrigerant port 7 communicates with the third refrigerant port 9 (the third refrigerant port at this time) 9 is connected to the heat exchanger of the outdoor unit), therefore, when the compressor stops during the refrigeration process, the controller 5 energizes the coil 4 so that the slider 6 is located at the right end of the main valve body 2, and the first refrigerant port 7 is connected to the second The four refrigerant ports 10 are connected; while the compressor is working during heating, the controller 5 energizes the coil 4, the slider 6 is located at the right end of the main valve body 2, and the first refrigerant port 7 communicates with the fourth refrigerant port 10, so When the compressor stops during the heating process, the controller 5 de-energizes the coil 4 so...

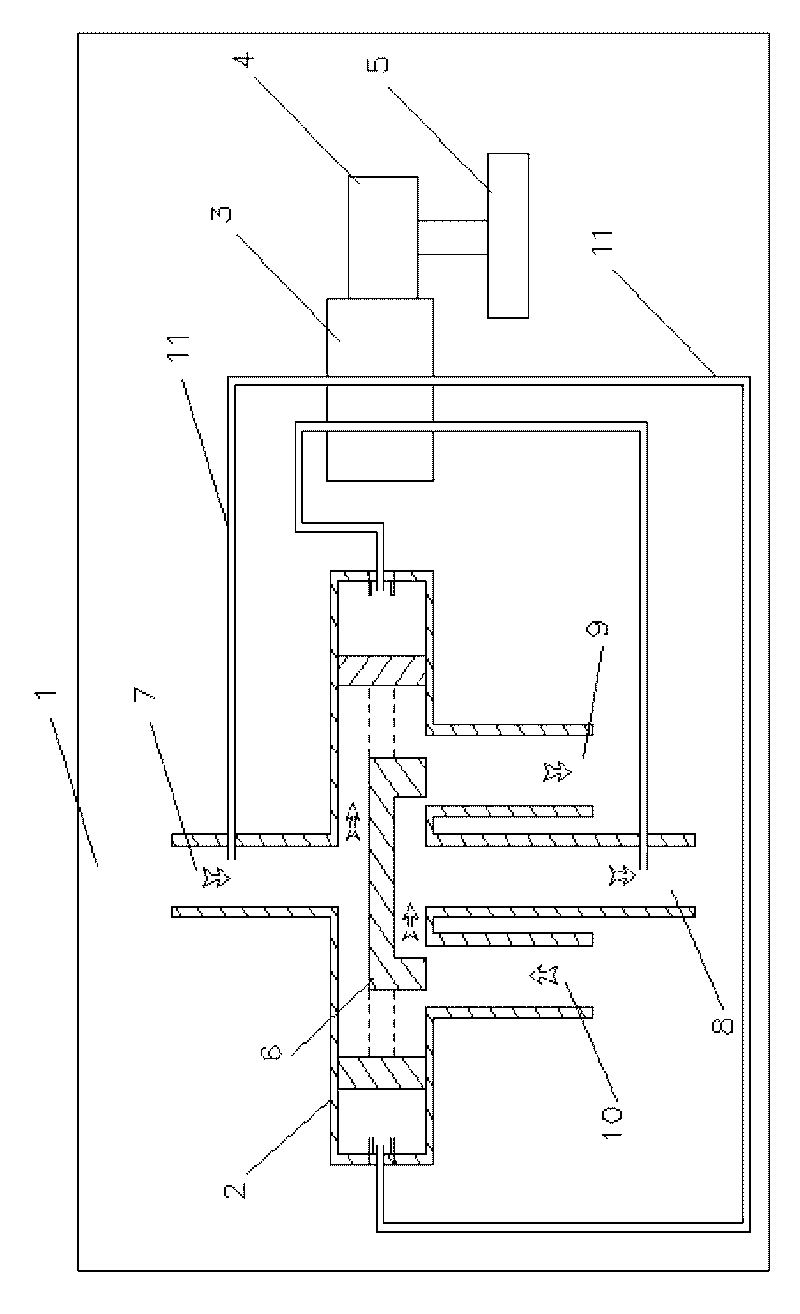

Embodiment 2

[0030] When the compressor is working during the refrigeration process, the controller 5 energizes the coil 4. At this time, the slider 6 is located at the right end of the main valve body 2, and the first refrigerant port 7 communicates with the fourth refrigerant port 10 (at this time, the fourth refrigerant port 10 It is connected to the heat exchanger of the outdoor unit), therefore, when the compressor stops during the cooling process, the controller 5 turns off the coil 4, makes the slider 6 located at the left end of the main valve body 2, and makes the first refrigerant port 7 and the second The three refrigerant ports 9 are connected; while the compressor is working during heating, the controller 5 turns off the coil 4, the slider 6 is located at the left end of the main valve body 2, and the first refrigerant port 7 communicates with the third refrigerant port 9, so When the compressor stops during heating, the controller 5 energizes the coil 4, so that the slider 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com