Three-dimensional slab heat pipe with multi-layer microporous pipe arrays and processing technique thereof

A flat heat pipe and processing technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems affecting the strength and reliability of flat heat pipes, low sealing and reliability performance, limited contact area, etc., to achieve efficiency and The effect of high maximum heat transport capacity and increased heat exchange density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described below in conjunction with the accompanying drawings.

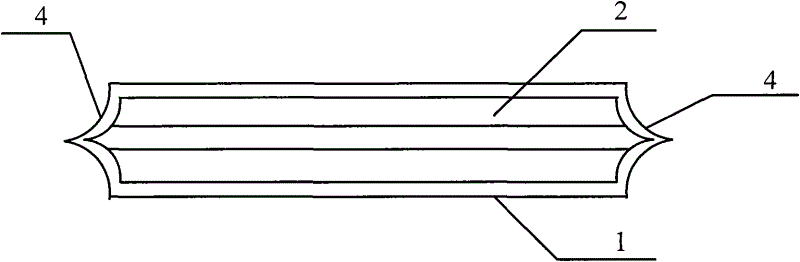

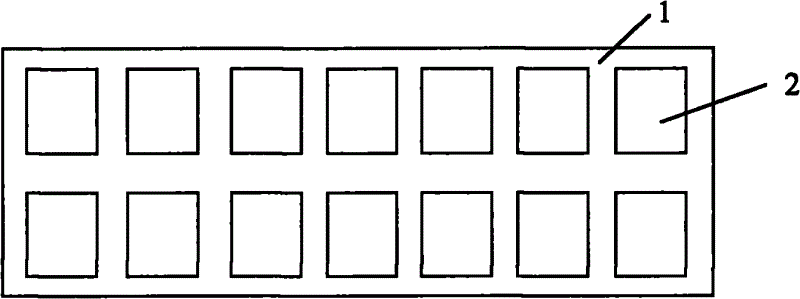

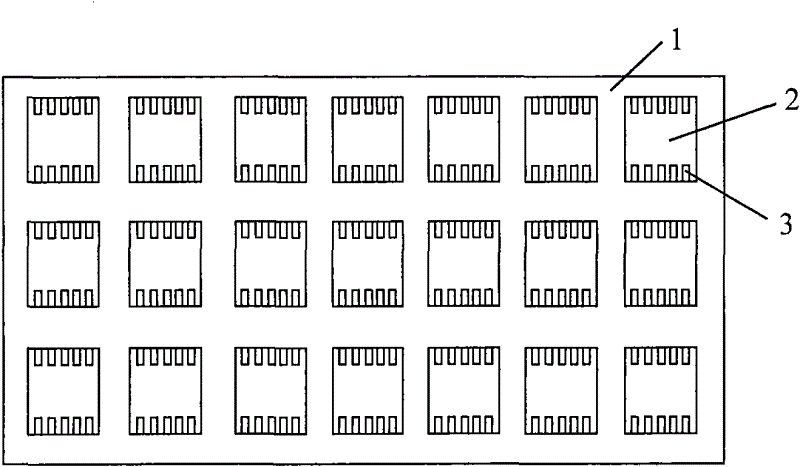

[0044] figure 2 It is a structural schematic diagram of the first embodiment of the three-dimensional flat heat pipe of the present invention, figure 2 The shown three-dimensional flat heat pipe with multi-layer microporous tube arrays includes a heat conductor 1 with two layers of parallel microporous tube arrays formed by extrusion or stamping of metal materials. The heat conductor 1 in this embodiment is Plate-shaped body, each layer of microporous tube arrays includes two or more microporous tubes 2 arranged in parallel, the parallel arranged microporous tubes 2 are parallel to the surface of the plate-shaped body with a wider lateral width, The cross-sectional shape of the channel of 2 is rectangular, and the microporous tube 2 is filled with a liquid working medium to form a micro heat pipe, which transfers heat in the form of phase conversion heat, naturally forming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com