Method for detecting reflective liquid level displacement based on angular displacement tracking

A reflective, angular displacement technology, applied in the directions of liquid level indicators, electromagnetic wave re-radiation, liquid/fluid solid measurement, etc., can solve the problems of large ultrasonic beam diameter, inapplicability, and influence on accuracy, and achieve a wide range of applications. High practicality and low interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

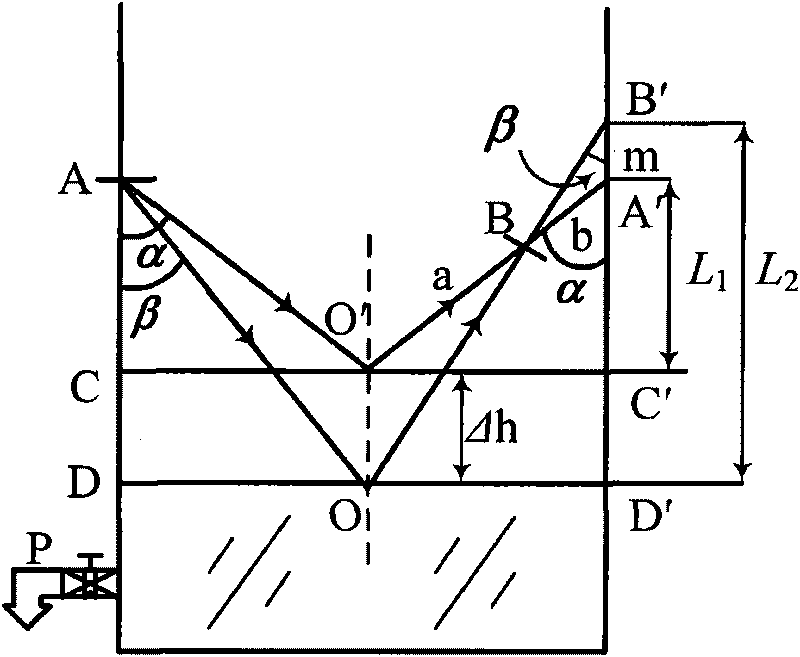

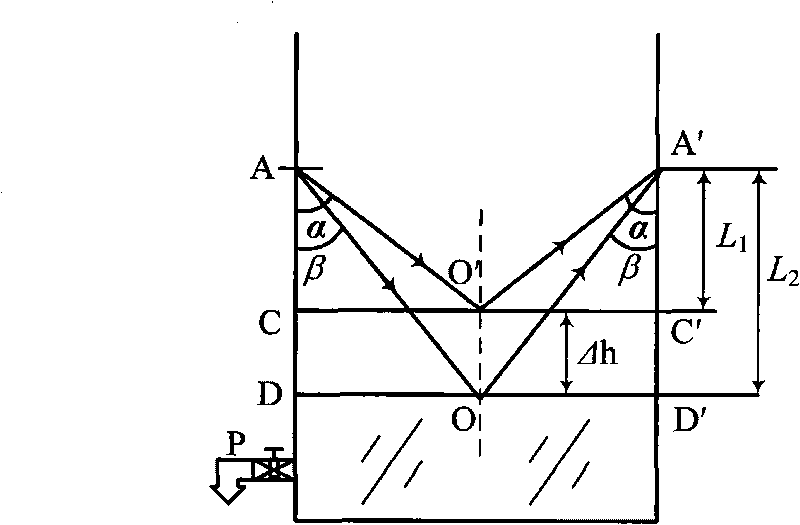

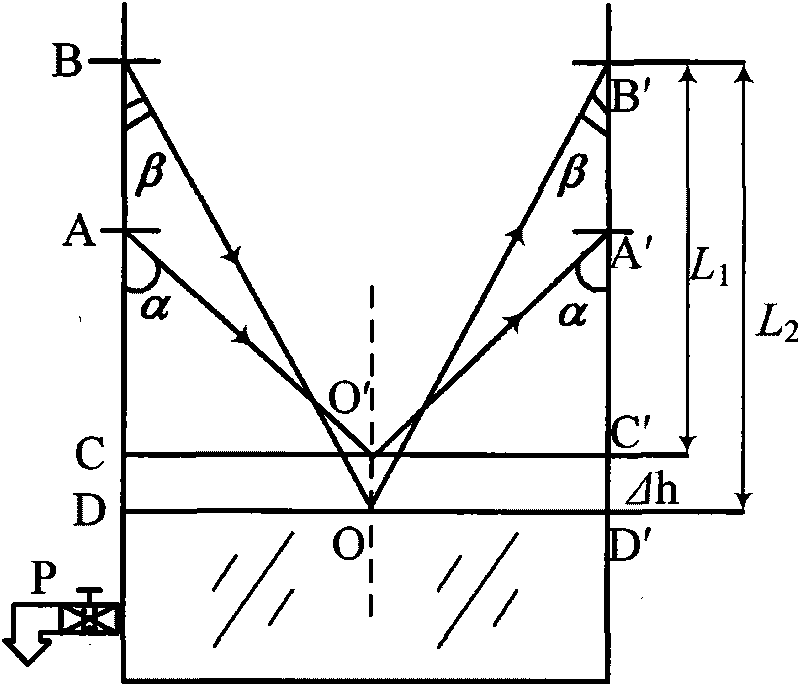

[0018] figure 1 , when the surface of the measured liquid passes through the position C-C', the reflected light of A is projected to point A' by the focusing lens, and the timing and tracking procedures are started by the corresponding circuit. If the value of the initial incident angle α is known, then by According to the trigonometry principle, the initial position of the liquid surface C-C' is:

[0019] L 1 = OC ′ ‾ · cot α

[0020] As the liquid flows out from the P port, the liquid will fall freely, and the emitted light will track and adjust the incident angle. When the liquid level drops to the D-D' position, the reflected light will be projected to the B' point by the lens, and the liquid will be obtained on the vertical detection surface. The imaging m of the surface displacement, after the detection of the photoelectric unit matrix, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com