Positive light advertising board device

A billboard and positive light technology, applied in display devices, light guides, optics, etc., can solve the problems that the size and shape cannot meet the lively advertising lighting, the uniformity of the light source is difficult to control, and the light utilization efficiency is low, so as to increase added value and avoid The effect of glare afterglow and low stray light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

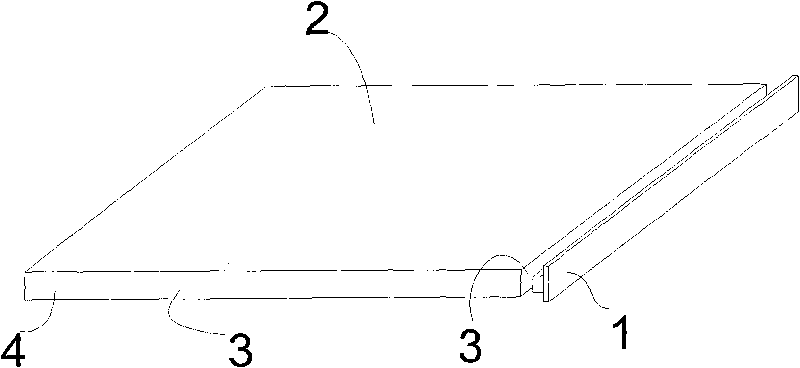

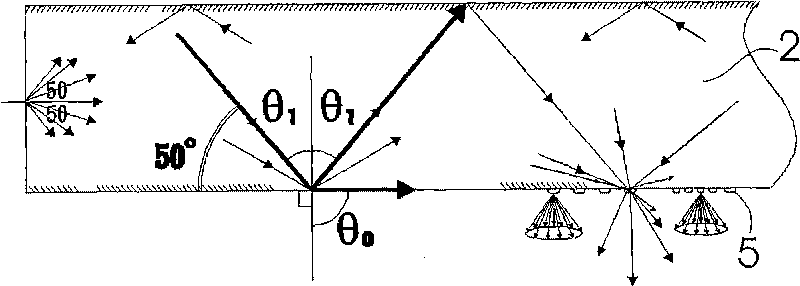

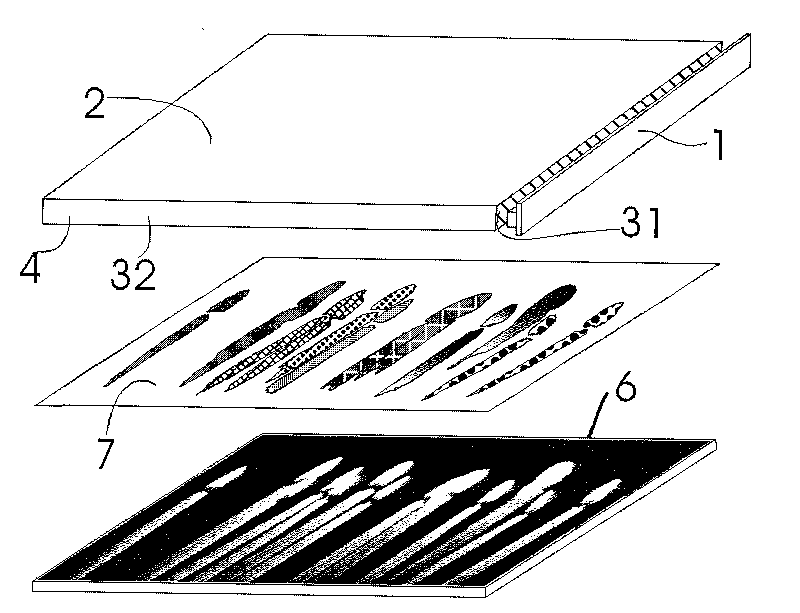

[0026] refer to figure 1 , 2 , 3. This embodiment includes a linear light source 1, a light guide plate 2, and the light guide plate 2 connects to the advertising drawing 6 through the surface of the transparent bump 5 without gaps; On the front of 6, the position of the transparent bump 5 is the outlet of the light in the light guide plate 2, and the distribution coating 7 of the transparent bump matches the content pattern of the advertisement drawing 6, producing a partially emphasized lighting effect.

[0027] The distribution, dot pitch, and height of the transparent bumps 5 can be varied depending on the artist's desired display effect, and there is no specific limitation.

[0028] One end surface 31 of the light guide plate 2 is provided with a linear light source 1, and the other end surface 32 is covered with reflective stickers 4; the linear light source 1 is formed by an arrangement of LED light sources (but not limited thereto).

[0029] The linear light source ...

Embodiment 2

[0031] refer to Figure 4 , this embodiment includes a light guide plate 2, a reflective LCD panel 10, and the transparent bump coating 11 is a macroscopic presentation of the fine transparent bumps printed on the light guide plate 2, with a gradient effect in which the center is dense and gradually loosens around, The linear light source 1 injected laterally can be compensated to form a uniform LED positive light plate 20 , and then positively contact the reflective LCD panel 10 to form an LCD billboard 30 illuminated by LED positive light.

[0032] Transparent bump coating 11, wherein the pitch of the transparent bumps in the central area of the light guide plate 2 is set to 0.15mm, then a better visual effect can be obtained, and the pitch of the transparent bumps in the edge area of the light guide plate 2 is set to 0.30mm, transparent The attenuation of the side light source can be compensated by a simple and gradual distribution of the convex points, so as to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com