Surface attaching type PTC (positive temperature coefficient) thermosensitive resistor and manufacture method thereof

A thermistor, mounting type technology, applied in the direction of resistors, resistors with a positive temperature coefficient, resistor manufacturing, etc., can solve the problem of resistors losing the PTC effect, to prevent oxidation, improve weather resistance, production The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

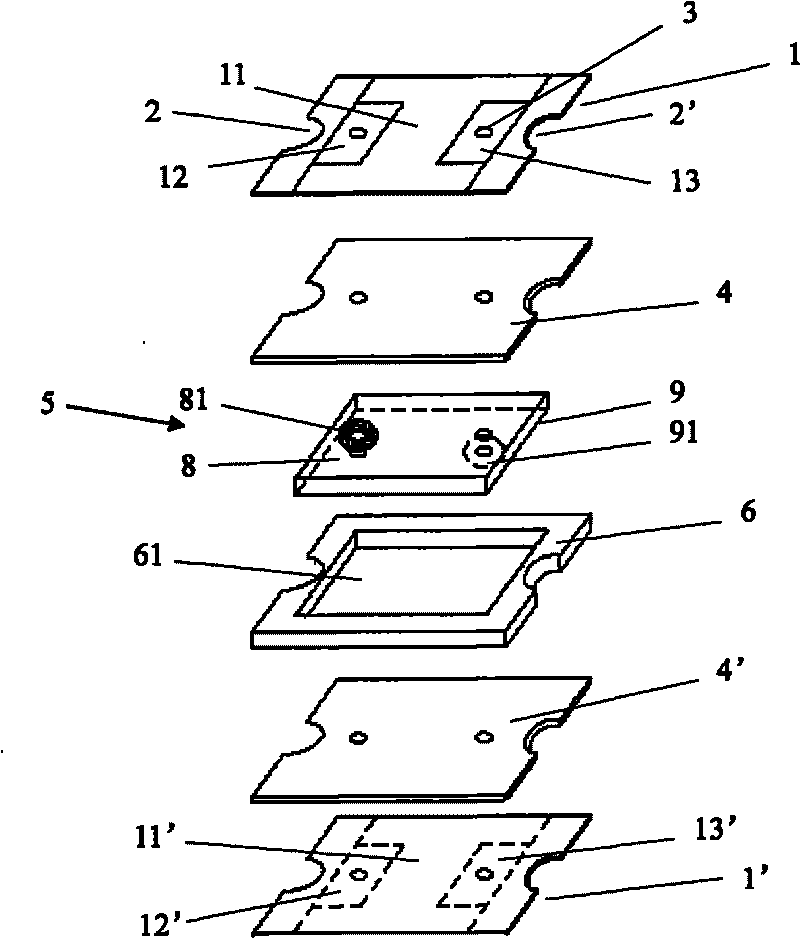

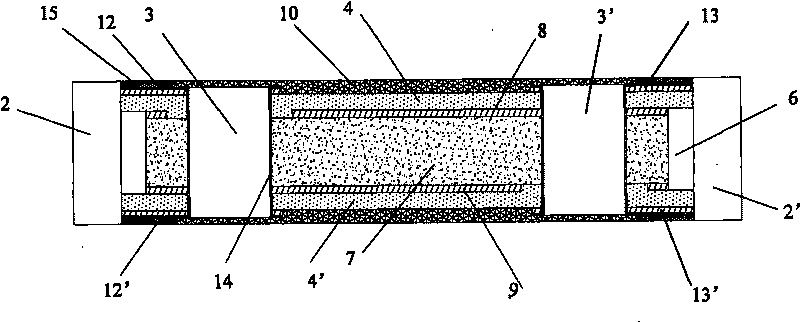

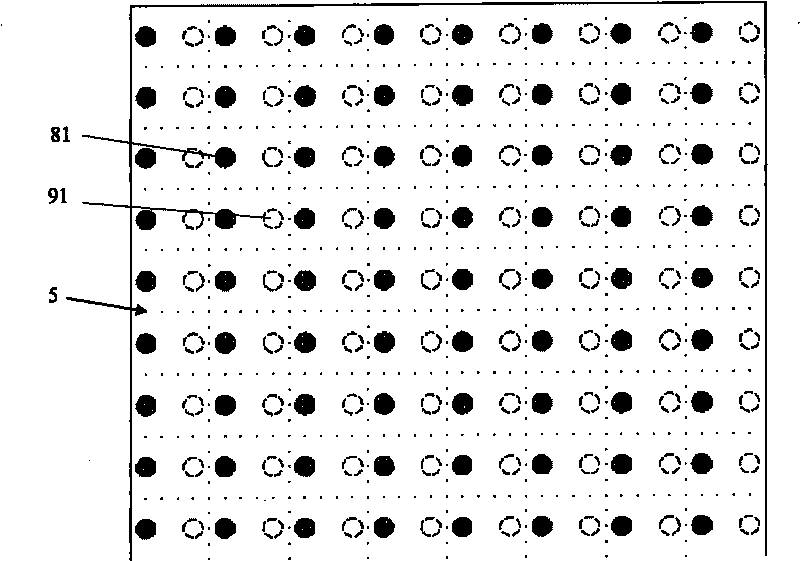

[0050] see figure 1 It is a schematic diagram of the decomposition structure of the present invention, figure 2 It is the schematic diagram of the sectional structure of the present invention and Figure 6 As shown in the perspective view of the surface mount type polymer PTC thermistor of the present invention, a surface mount type PTC thermistor includes a chip 5, and the chip 5 is covered by a core material 7 and covered on the core material 7. Two metal electrodes 8, 9 are formed on the surface, and the chip 5 is covered by an epoxy resin layer 6, and the upper and lower surfaces are pasted with semi-cured resin materials 4, 4' and external electrodes 1, 1' to form a composite core material. The chip surface electrodes 8, 9 are connected with the external electrodes 1, 1' through the product terminal through hole 2 and the product internal through hole 3. Chemical etching process is used to remove part of the metal foil on the outer surface, thereby forming the path of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap