Interlayer dielectric layer, interconnection structure and manufacturing method thereof

A technology of an interlayer dielectric layer and a manufacturing method, which is applied to the interconnection structure and its manufacturing, and the field of the interlayer dielectric layer, can solve the problems of increased reflection and scattering, easy cracking, and large stress, and achieves reduced reflection and scattering. Not easy to crack, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

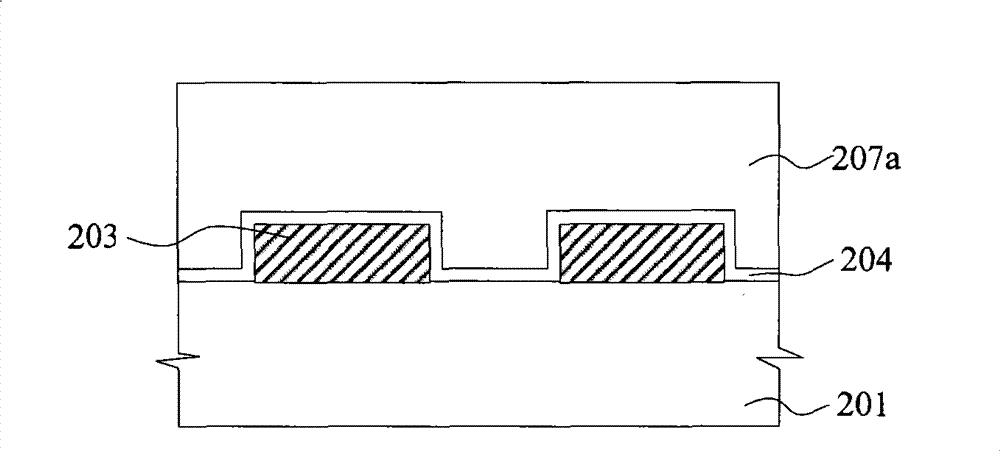

[0032] The interlayer dielectric layer of the present invention adopts a fluorine-free dielectric layer, which avoids the easy diffusion of fluorine in the fluorine-containing oxide of the prior art, and does not need to add a first oxide layer for isolation and a fourth oxide layer in between. To repair defects, the number of interlayer dielectric layers formed is small, the structure is simple, and the cost is low; the reflection and scattering of light between layers are reduced, and the transmittance is high; and because of the small number of layers, the interlayer The stress is small, and it is not easy to cause cracking.

[0033]Below by describing specific embodiment in detail according to accompanying drawing, above-mentioned object and advantage of the present invention will be clearer:

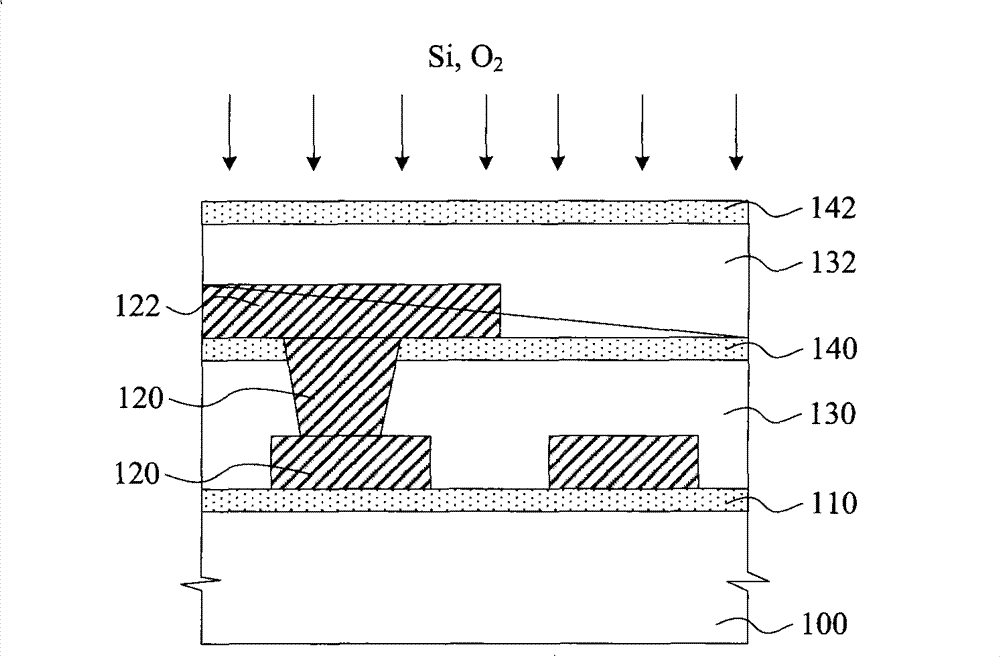

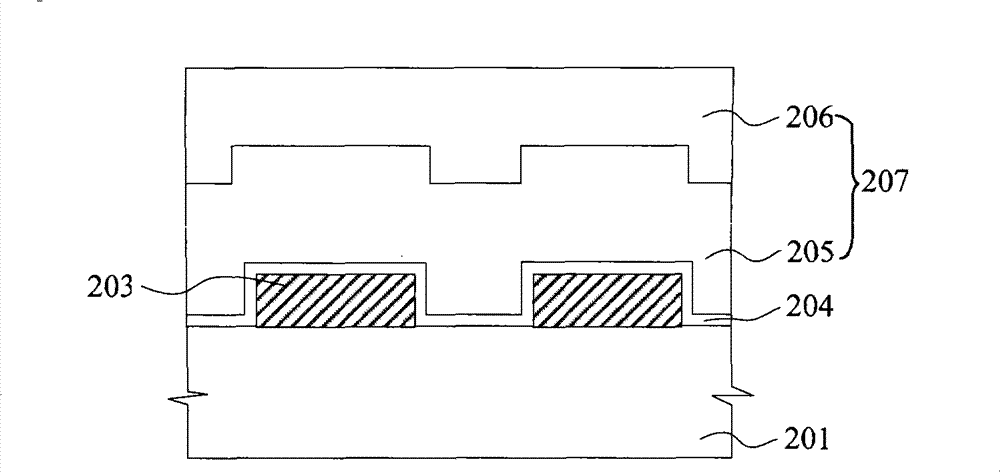

[0034] refer to Figure 6 , the present invention firstly provides a method for manufacturing an interlayer dielectric layer in a CMOS image sensor, comprising: providing a semicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com