Solar panel and method for making same

A technology of solar panels and solar cells, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of limited performance improvement of solar cells, inability to directly use solar cells, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0149] experiment method

[0150] 1. Fabrication of solar panels

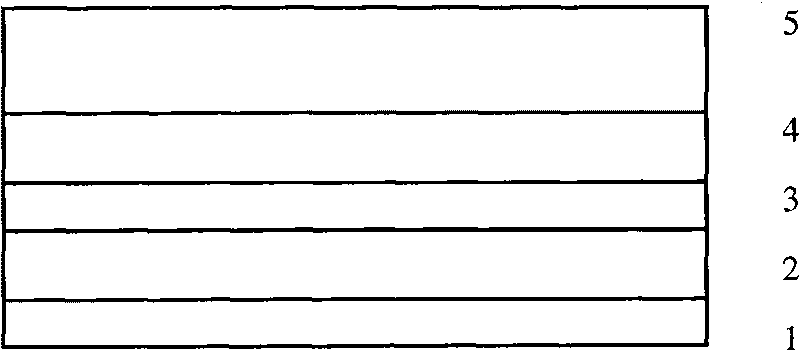

[0151] The polymer sheet used to form the encapsulant layer was prepared by the method described in the present invention, and according to figure 1 The structure shown is packaged into a battery. The process used for solar cell module packaging includes cell sorting, single welding, string welding, stacking, lamination, framing and cleaning.

[0152] 2. The output power test method of solar panels

[0153] The solar cell panel manufactured by the above method was tested by a 3500SLP component tester (purchased from Spire Company of the United States) to obtain the output power value.

Embodiment 1

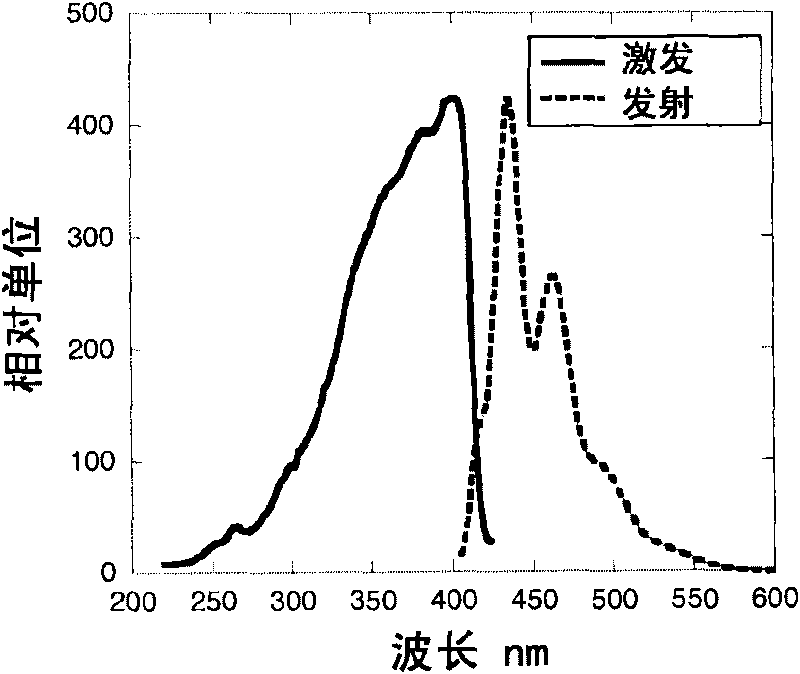

[0159] With ethylene-vinyl acetate copolymer resin (DuPont, vinyl acetate content is 33%) and by the weight of this ethylene-vinyl acetate copolymer resin, the crosslinking curing agent 2 of 5000ppm, 5-dimethyl- 2,5-bis(tert-butylperoxy)ethane, 1000ppm antioxidant tris(2,4-di-tert-butylphenyl) phosphite, 1000ppm hindered amine light stabilizer bis(1-octyl) Oxygen-2,2,6,6-tetramethyl-4-piperidinyl)decanediester, 500ppm of tackifier γ-amino acid triethoxysilane and 200ppm of 1,2-bis The mixture of [4-(2-benzoxazolyl)phenyl](CAS 1533-45-5) is blended and extruded with an extruder, and then passed through the casting process described in Chinese patent application No. 200510034750.1 Cooling, traction, and winding processes, namely to prepare a polymer encapsulation layer with a thickness of 0.5 mm.

[0160]

[0161] Use 3.2 mm thick low-iron ultra-clear tempered glass (purchased from CSG Solar Glass Co., Ltd.) as the front plate, TPT from Austria Isovolta Company as the back p...

Embodiment 2

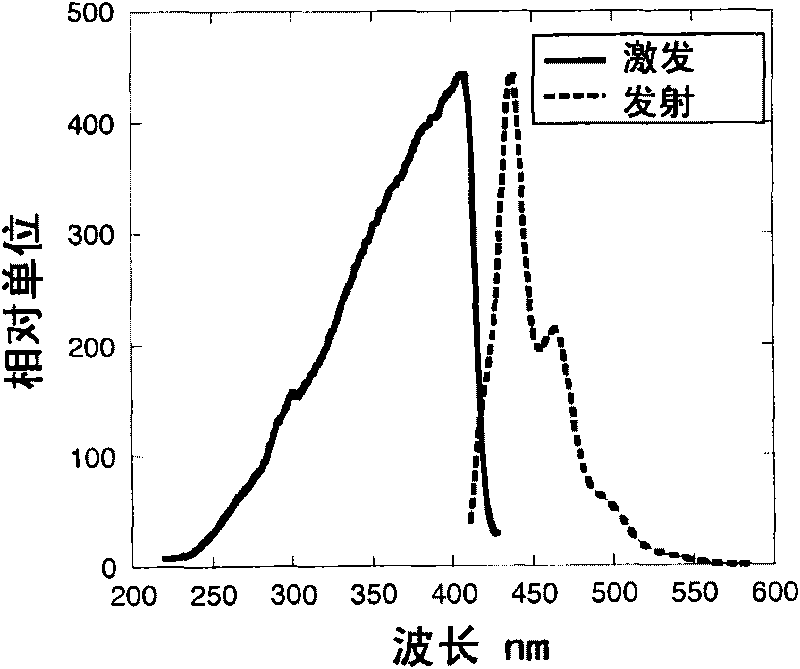

[0169] With ethylene-vinyl acetate copolymer resin (DuPont, vinyl acetate content is 33%) and by the weight of this ethylene-vinyl acetate copolymer resin, the crosslinking curing agent 2 of 5000ppm, 5-dimethyl- 2,5-bis(tert-butylperoxy)ethane, 1000ppm antioxidant tris(2,4-di-tert-butylphenyl) phosphite, 1000ppm hindered amine light stabilizer bis(1-octyl) Oxygen-2,2,6,6-tetramethyl-4-piperidinyl)decanediester, 500ppm of tackifier γ-amino acid triethoxysilane and 800ppm of 1,4-bis( The mixture of 2-benzoxazolyl)naphthalene (CAS 5089-22-5) is blended and extruded with an extruder, and then passed through the casting, cooling, pulling, and winding described in the Chinese patent application with application number 200510034750.1 The process is to prepare a polymer encapsulation layer with a thickness of 0.5 mm.

[0170]

[0171] Use 3.2 mm thick low-iron ultra-clear tempered glass (purchased from CSG Solar Glass Co., Ltd.) as the front plate, TPT from Austria Isovolta Compan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com