Motor shaft replacing tool and shaft replacing method thereof

A technology for motor shafts and tools, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc. It can solve the problems of winding insulation damage, safety and reliability cannot be guaranteed, clamping, hoisting, turning over and other problems, and achieves a simple structure , The effect of clamping the rotor iron core is stable and safe, and the method of shaft replacement is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

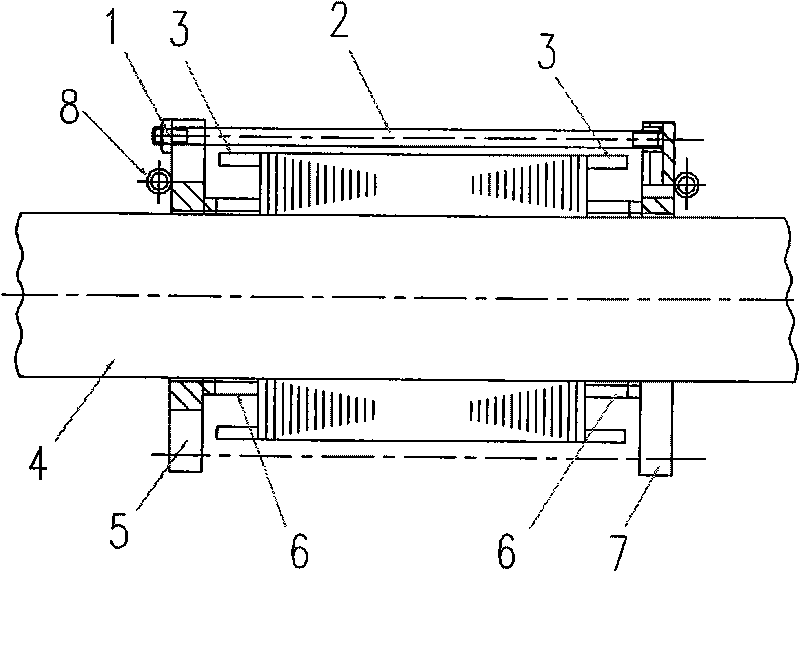

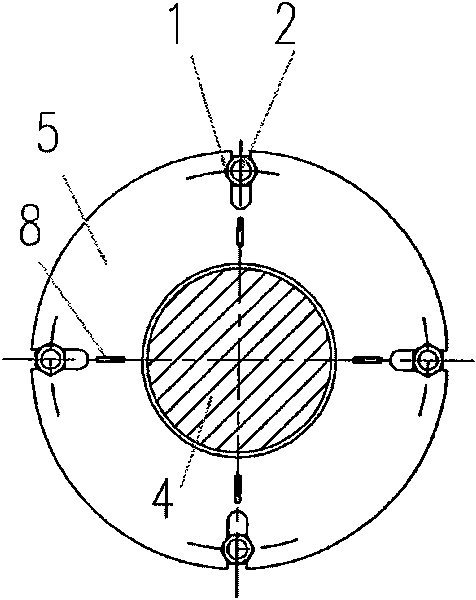

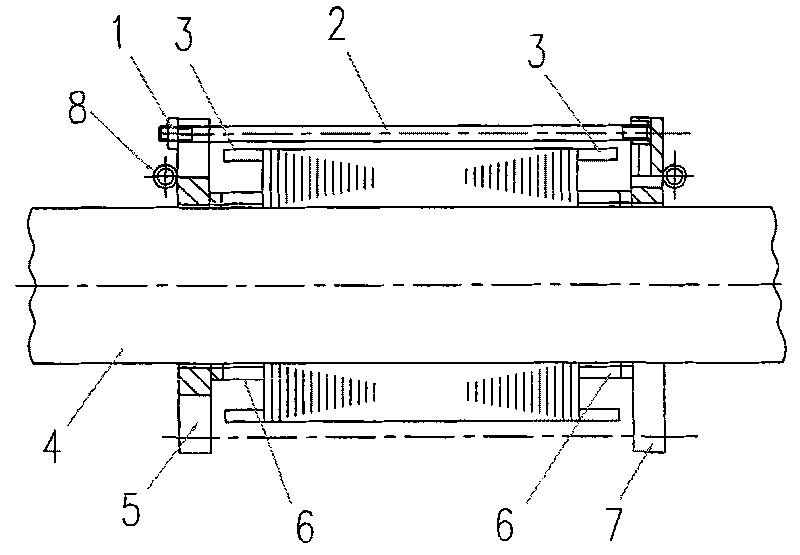

[0018] As shown in the figure, the shaft changing tool of the present invention includes a symmetrical upper pressing plate 5 and a lower pressing plate 7 with a central hole, a symmetrical adjustable pull rod 2, and the upper pressing plate 5, the lower pressing plate 7, and the pulling rod 2 are connected to form a fixed frame structure. The distance between the upper pressing plate and the lower pressing plate can be adjusted by adjusting the pull rod 2 . The two ends of the pull rod 2 in this embodiment are screw rods, one end of which is fitted and connected with the screw hole on the upper platen or the lower platen, and the other end passes through the connecting hole on the lower platen or the upper platen and is connected by the nut 1. The distance between the upper pressing plate and the lower pressing plate can be adjusted. The diameter of the central hole of the upper pressing plate and the lower pressing plate cannot be smaller than the diameter of the rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com