Linear motor for stirling refrigerator with axial magnetic path

A linear motor, axial magnetic circuit technology, applied in electromechanical devices, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc. Pull force and other problems to achieve the effect of prolonging life and avoiding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

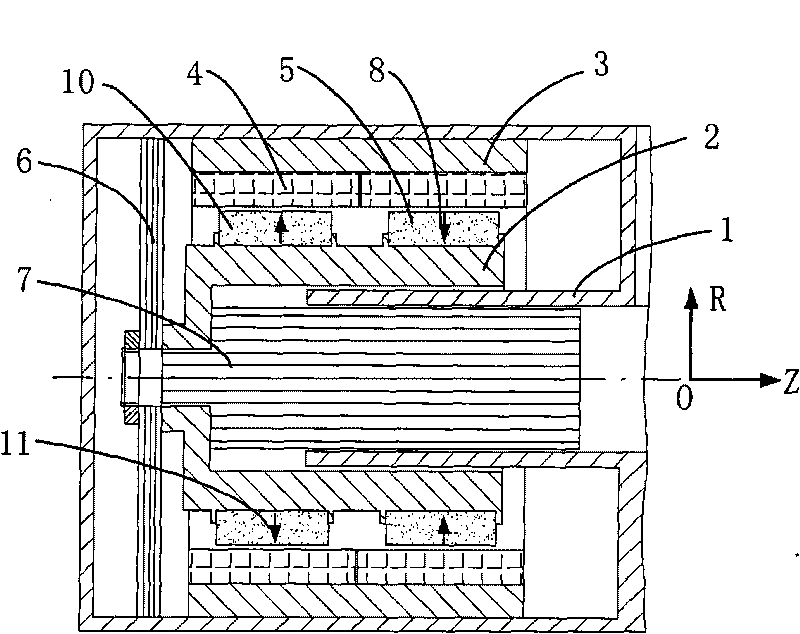

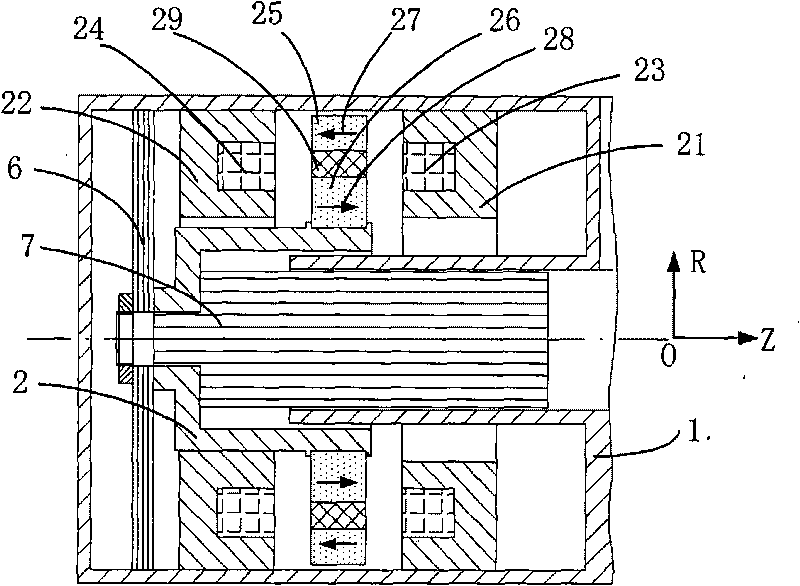

[0027] Please refer to the accompanying drawings for a further description of the present invention.

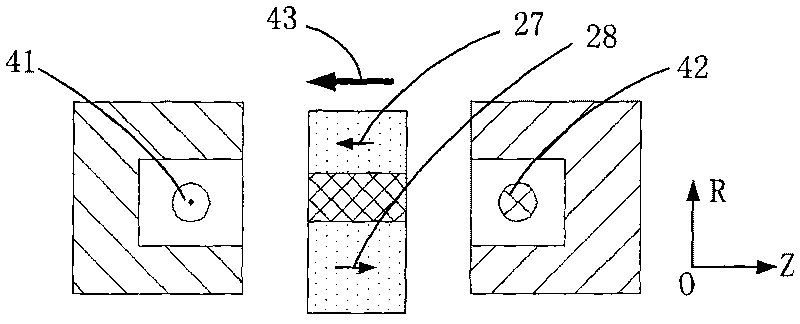

[0028] Such as figure 2 As shown, the present invention provides a linear motor for an axial magnetic circuit Stirling refrigerator, comprising a stator, a mover and a leaf spring 6, and the stator is composed of a housing 1, a left stator core 22, a left stator coil 24, a right The stator iron core 21, the right stator coil 23 and the leaf spring 6 are composed, the mover is composed of the inner magnet steel 26, the outer magnet steel 25, the mover support 2 and the piston 7, and the inner magnet steel 26 and the outer magnet steel 25 use a magnetic isolation ring 29 apart, the magnetization directions of the inner magnet steel 26 and the outer magnet steel 25 are opposite, and both are axial magnetization.

[0029] The outer side of the leaf spring 6 is connected to the motor stator, and the inner side is connected to the motor mover, and can support the mover for axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com