Stirring propeller for sucking and dispersing easy-to-self-polymerized gas

A stirring paddle, gas technology, applied in mixers with rotating stirring devices, chemical instruments and methods, dissolution and other directions, to achieve high stirring efficiency, good dispersion effect, and reduce gas delivery pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

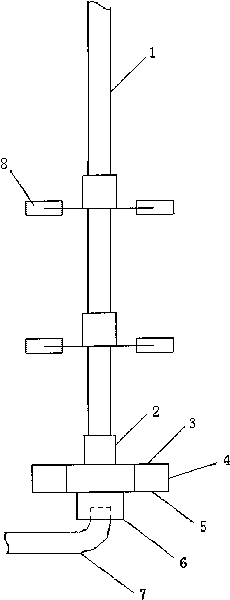

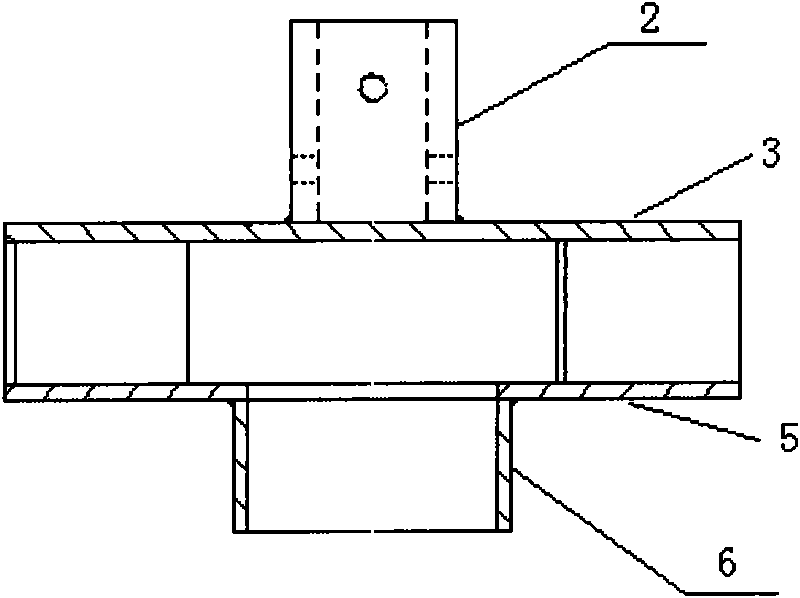

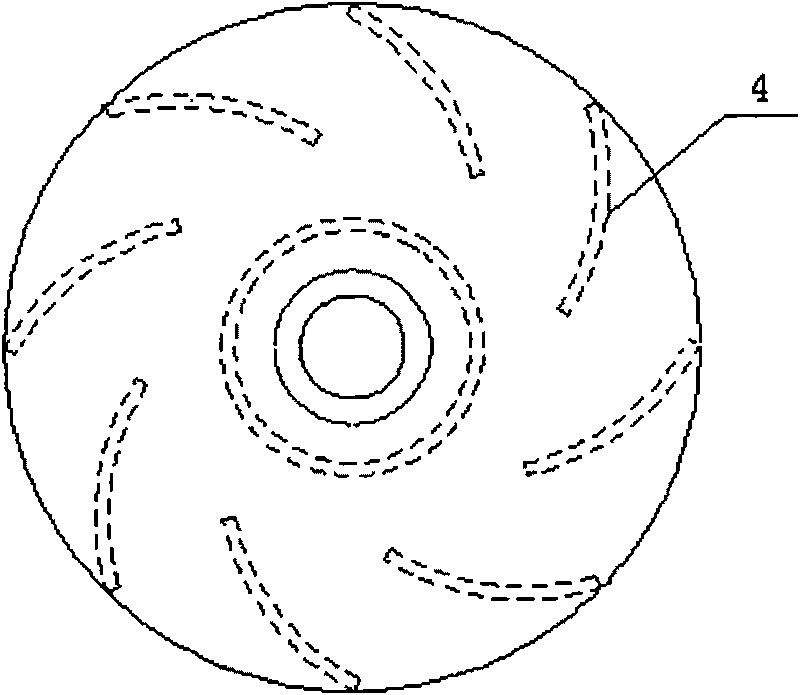

[0014] figure 1 , figure 2 , image 3 It is a structural schematic diagram of an embodiment of the present invention,

[0015] Such as figure 1 and 2 As shown, a vertical cylindrical paddle shaft 1, the end of the paddle shaft 1 is connected with the upper disc 3 through the fixed ring 2, the center of the lower disc 5 is provided with an air inlet, and a short pipe is welded around the lower side of the air inlet as a Air intake guide tube 6, easy self-gathering gas intake pipe 7 ends are placed in the intake guide tube 6. Depend on image 3 It can be seen that the upper disk 3 and the lower disk 5 are connected by arc-shaped blades 4 to form a curved-blade disk turbine. The arc-shaped blades 4 are distributed in a turbine-like shape, with a total of 8 pieces and a cavity in the center. 1 to 4 layers of stirring paddles can be installed on the stirring shaft, and each layer of paddles contains 2 to 12 Rushton turbine blades 8 . figure 1 Two layers of Rushton turbine b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com