Special device for sealing machine of fuel tank

A special equipment and sealing machine technology, applied in the field of special equipment for fuel tank sealing machines, can solve the problems of low degree of automation, time-consuming and laborious, and achieve the effects of low rework rate, production cost reduction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

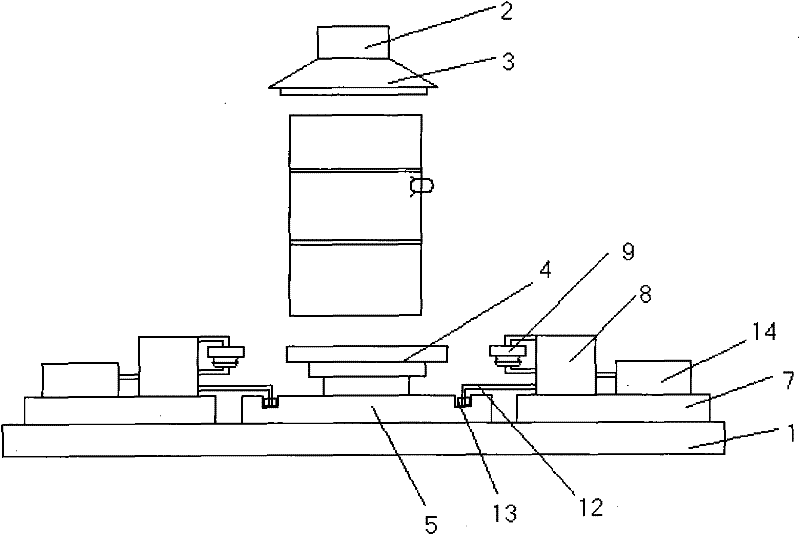

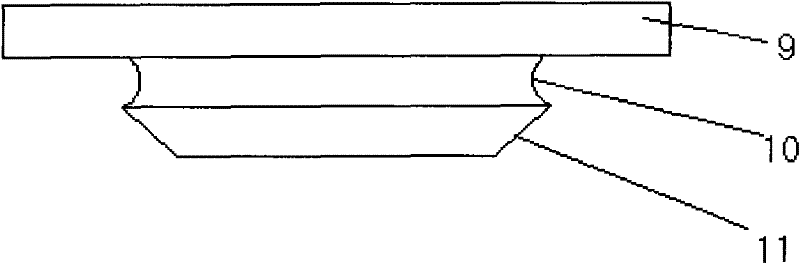

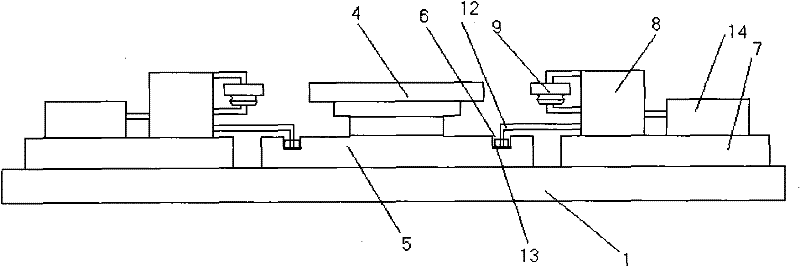

[0013] A special equipment for a fuel tank sealing machine, comprising a horizontal workbench 1, a column 2 is provided on one side of the workbench 1, a cantilever is provided at the top of the column 2, and a lifting shaft 3 is installed on the cantilever, and the lifting shaft 3 A pressing plate is provided at the lower end of the workbench, and a central axis is installed in rotation on the worktable, and a cylindrical sealing mold 4 is fixedly connected to the upper end of the central axis. The outer wall shape of the sealing mold 4 is the same as that of the outer wall of the fuel tank to be sealed. There is an edge 5 at the lower end of the sealing mold 4, and there is a ring groove 6 surrounding the outer wall of the sealing mold 4 in the edge 5, and the oil tank is clamped between the pressure plate and the sealing mold 4, and the central axis is driven by a motor to drive the sealing mold 4 and the oil tank to rotate; On the left and right side workbenches of the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com