Jigsaw blade for hand-held power jigsaws

A technology for reciprocating saws and piercing saw blades, applied in the field of reciprocating saw blades, can solve problems such as clamping end damage, and achieve the effects of increasing bending load, improving cutting efficiency, and improving cutting efficiency and cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

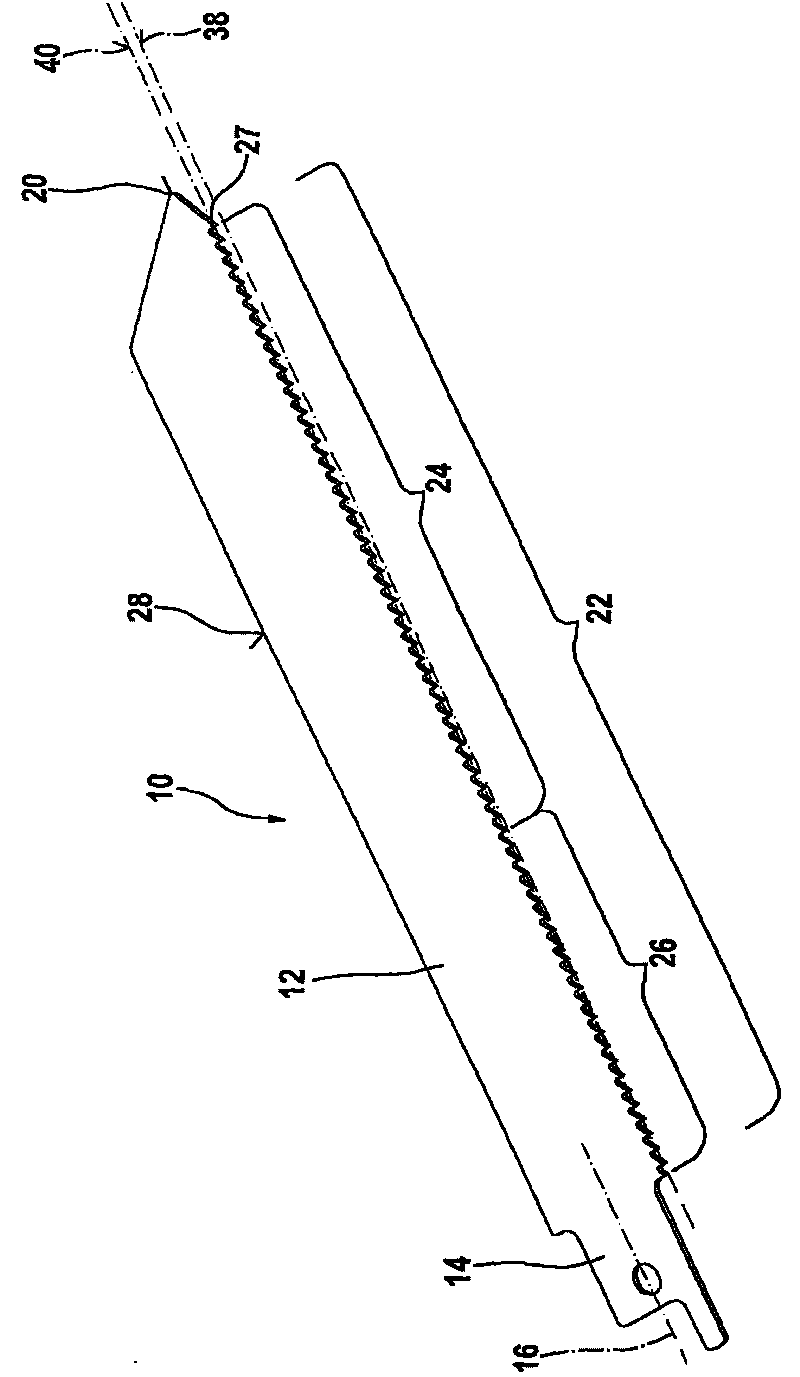

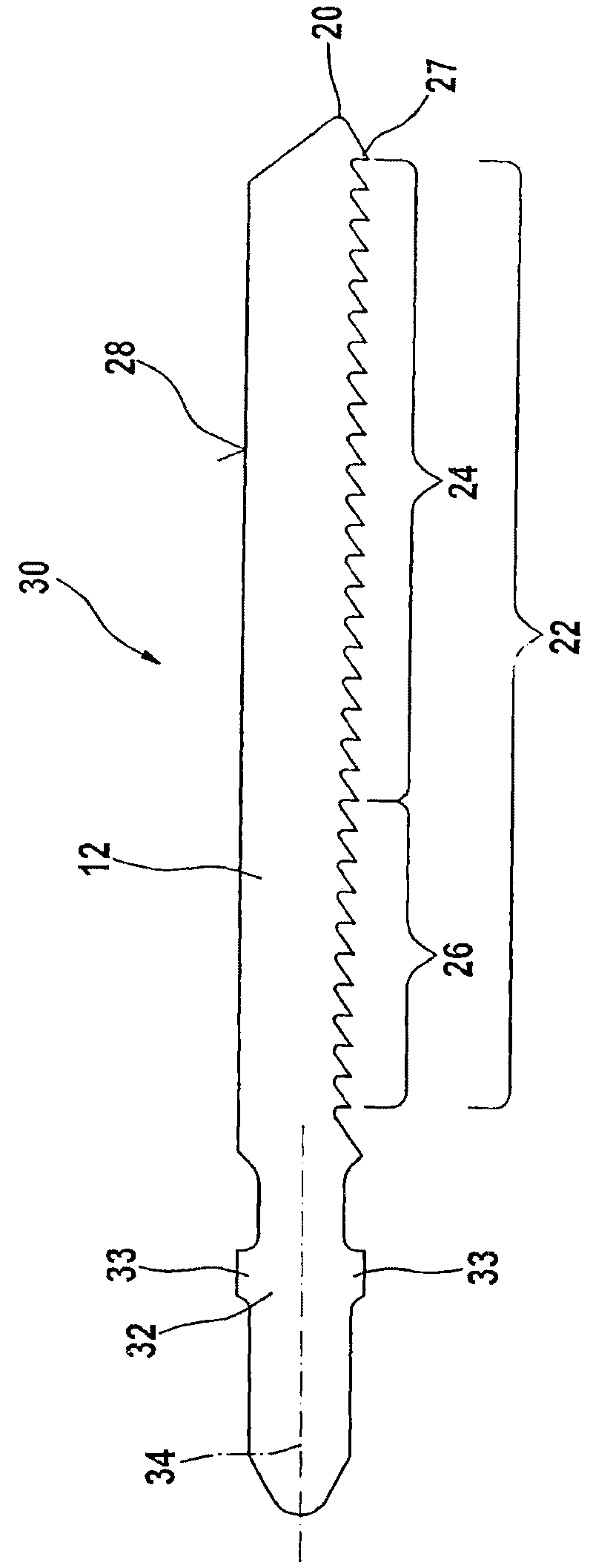

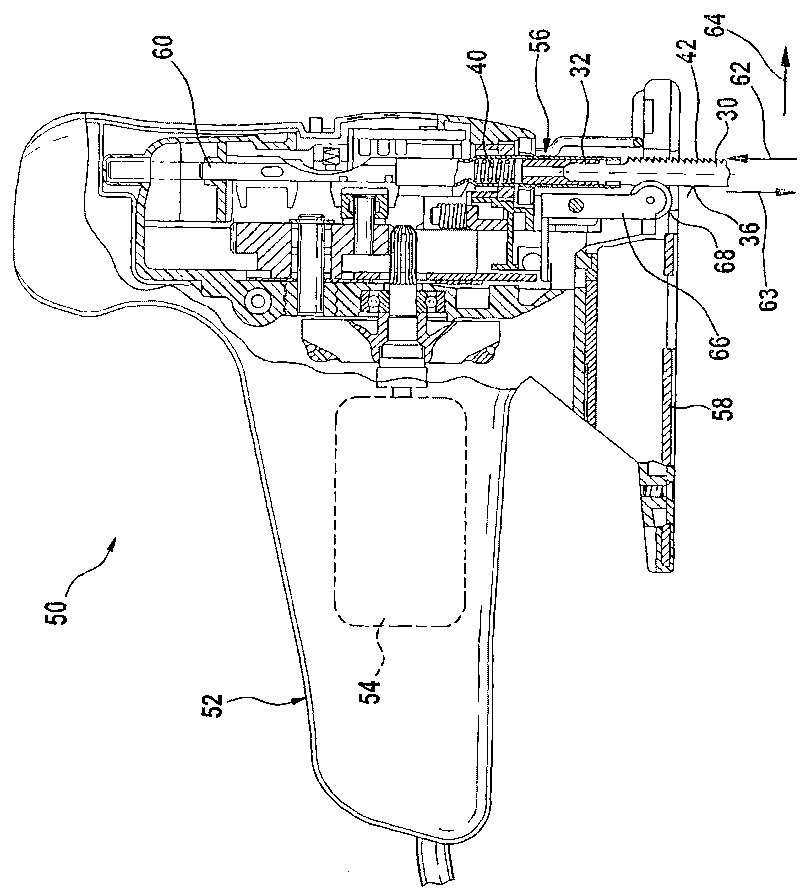

[0022] exist figure 1 The saw blade 10 for a saber saw according to the invention shown in the figure comprises a longitudinal, flat, blade-like working body 12 which has a clamping end 14 at the rear and a saw blade at the front Tip 20. The clamping end 14 has a central axis 16 and is smaller in width than the working body 12 , so that it is relatively sensitive to large bending moments in the plane of the saw blade 10 . A rearwardly extending tooth row 22 adjoins the saw blade tip 20 on the lower plane side. The saw blade back 28 extends on the rear or top plane side of the working body 12 .

[0023] In this case, the first tooth row region 26 of the tooth row 22 , which directly adjoins the clamping end 14 , is inclined at a positive angle of approximately 5° relative to the axis 16 of the clamping end 14 in the rearward viewing direction. The inclined dentition zone 26 occupies approximately ⅓ of the length of the dentition 22 and transitions into a further dentition zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com