Electric tool

A technology of electric wood milling and output shaft, which is applied in wood processing appliances, forming/shaping machines, manufacturing tools, etc., to achieve the effects of simple structure, reduced number of impacts, and reasonable impact speed and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

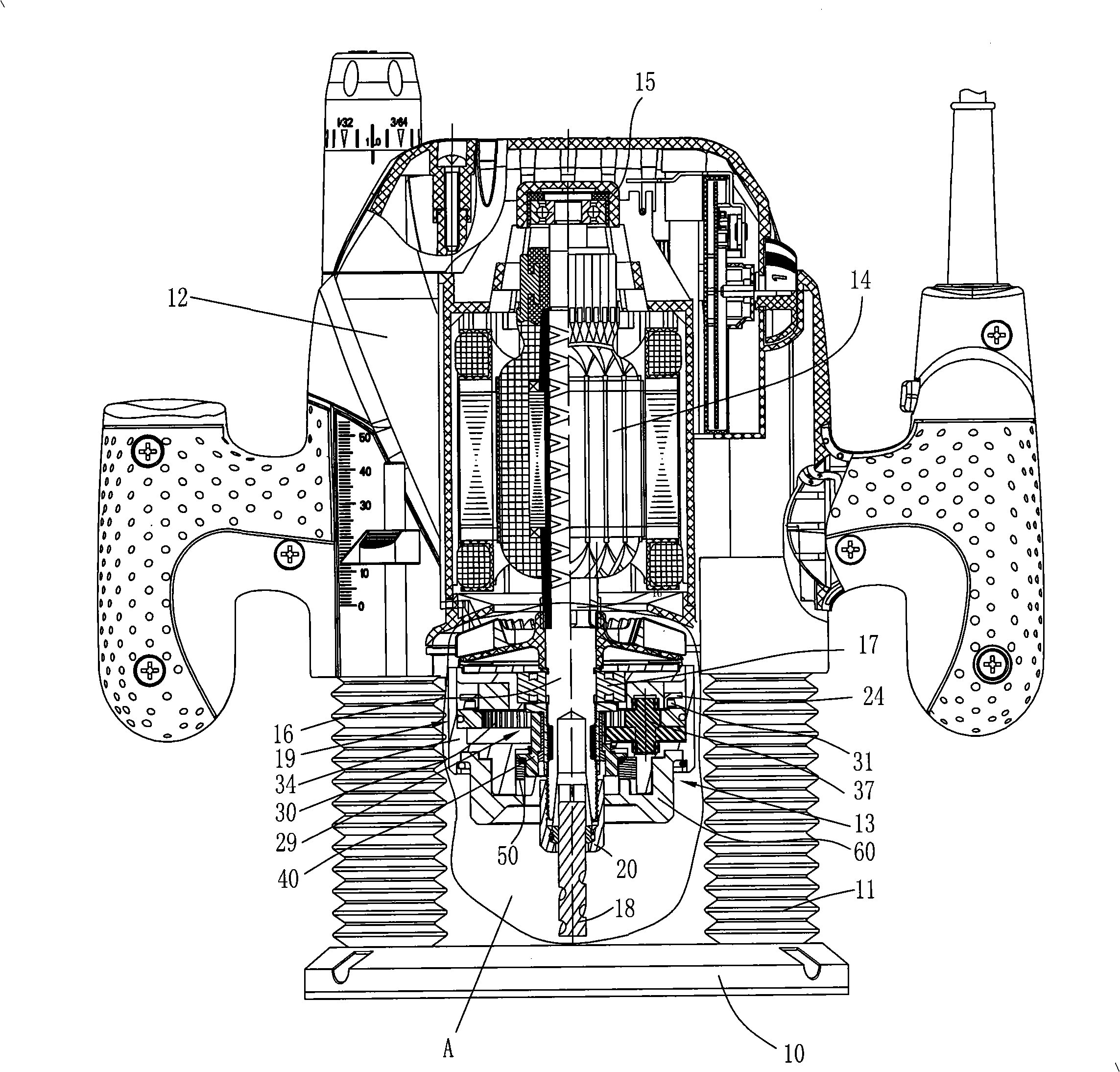

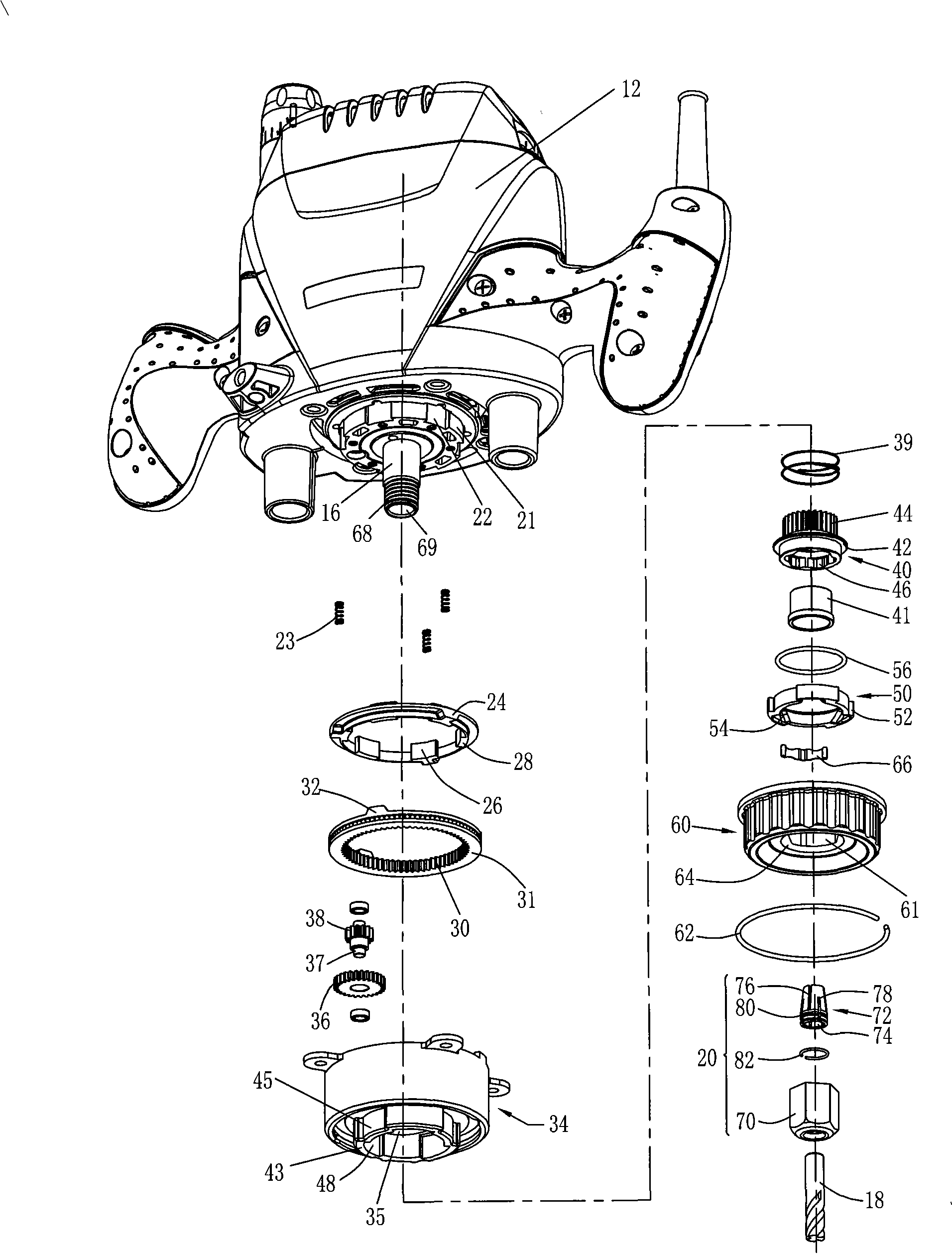

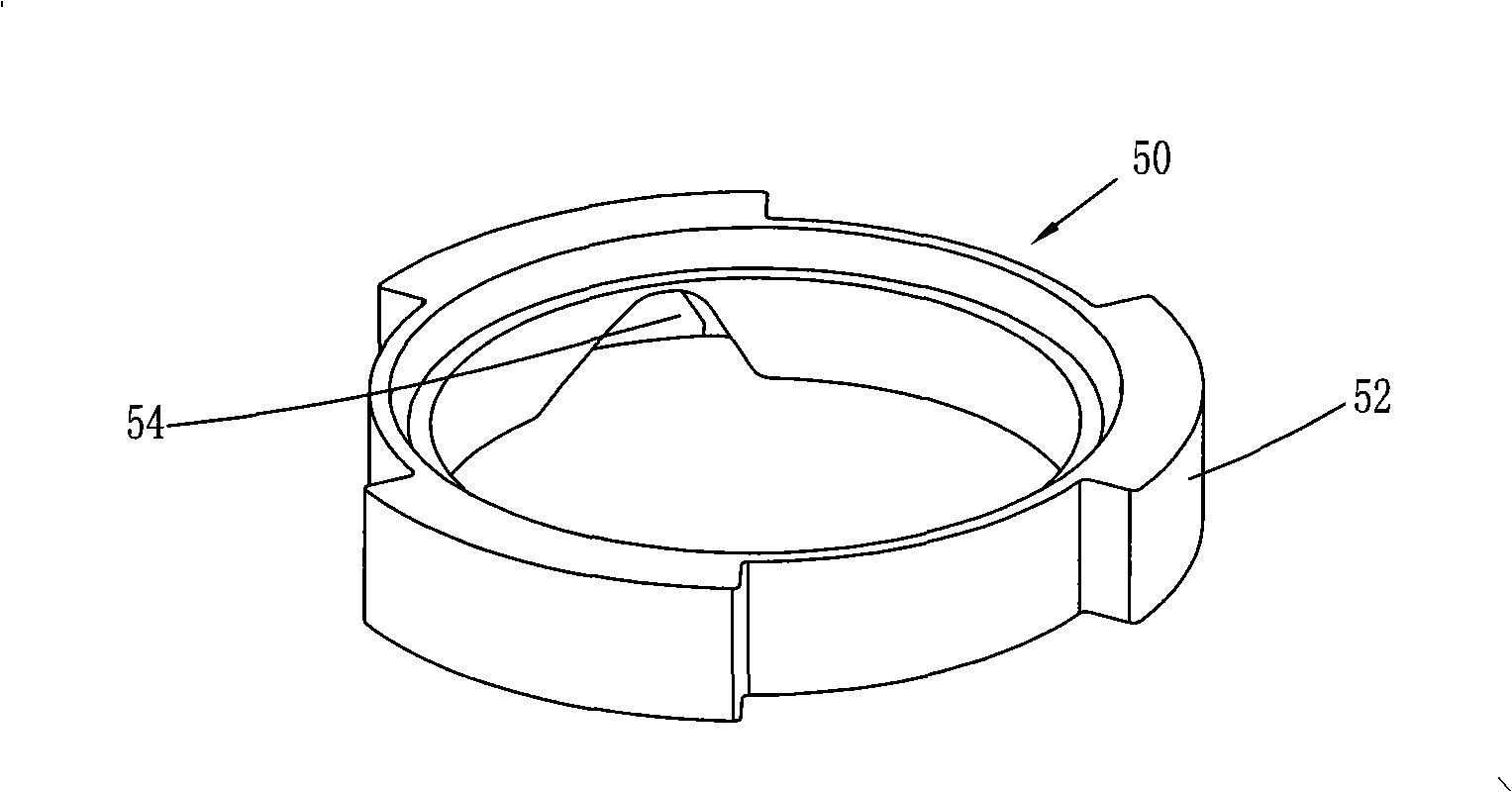

[0045] refer to figure 1 As shown, the electric wood miller in the preferred embodiment of the present invention includes a horizontal base 10, a guide post 11 extending vertically upward from the base 10, a casing 12 that is movably socketed on the guide post 11, and the inside of the casing 12 is hollow. There is a motor 14 placed vertically, and the two ends of the motor 14 are respectively supported on the casing 12 through bearings 15 and 17. The output shaft 16 of the motor 14 protrudes downwards from the casing 12, and connects the output shaft 16 with the tool 18. The polygonal collet 20 is connected, and a spin device 13 is arranged between the casing and the collet, and the spin device 13 includes an impact device 19 that impacts the collet by a driving force of a motor. Impact device 19 comprises impact ring 24, circular ring 31, casing end cover 34 and deceleration mechanism 29, and deceleration mechanism 29 comprises ring gear 30, deceleration shaft 37, guide sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com