Adhesive block film for flexible printed circuit board fast compression technology

A flexible printing and circuit board technology, applied in the field of adhesive film, can solve the problems of insufficient heat resistance of PE, poor effect of anti-overflow adhesive, air breakage, etc., to achieve the effect of ensuring flatness, avoiding pollution, and avoiding filling failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

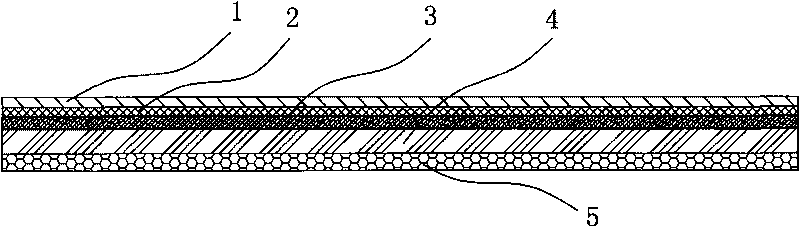

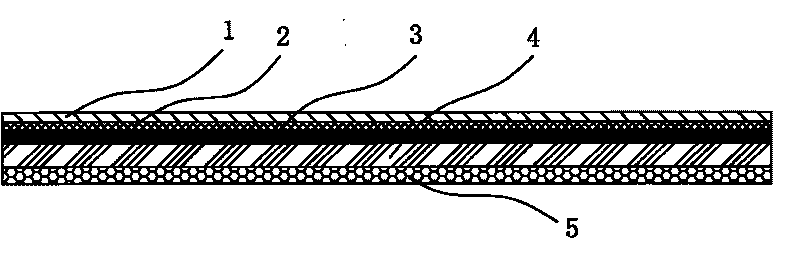

[0024] Embodiment one: see attached figure 1 As shown, an adhesive barrier film used in the fast pressing process of flexible printed circuit boards is composed of a coated paper layer 1 and an adhesive barrier layer. The adhesive barrier layer includes a polyethylene layer 2, a polyethylene - Nylon permeable layer 3, nylon layer 4 and anti-adhesive liquid layer 5 adsorbed on the outer surface of the nylon layer.

[0025] In this embodiment, the thickness of the nylon layer is between 8 microns and 250 microns, and the thickness of the polyethylene layer is 15 microns to 50 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com