Processing method of water-repelling ventilating cellulose fiber knitted fabric

A cellulose fiber and knitted fabric technology, applied in fiber treatment, plant fiber, fabric surface trimming, etc., can solve the problem of affecting the perspiration, air permeability and wearing comfort of the fabric, the hydrophilic effect is not ideal, and the hydrophilicity of the fabric is damaged. It can achieve excellent frontal water repellency, improved gloss and feel, and lasting finishing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

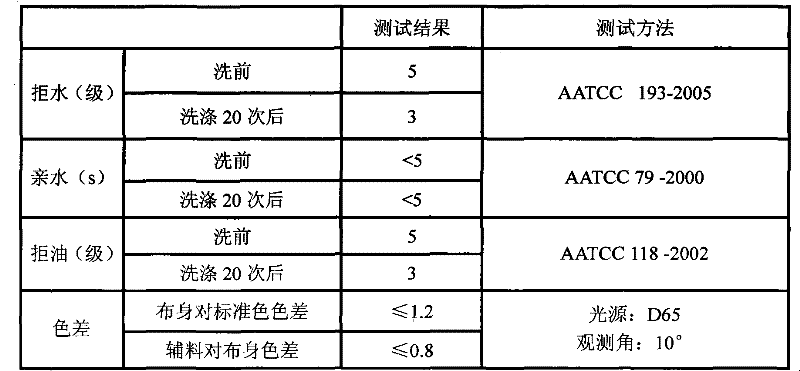

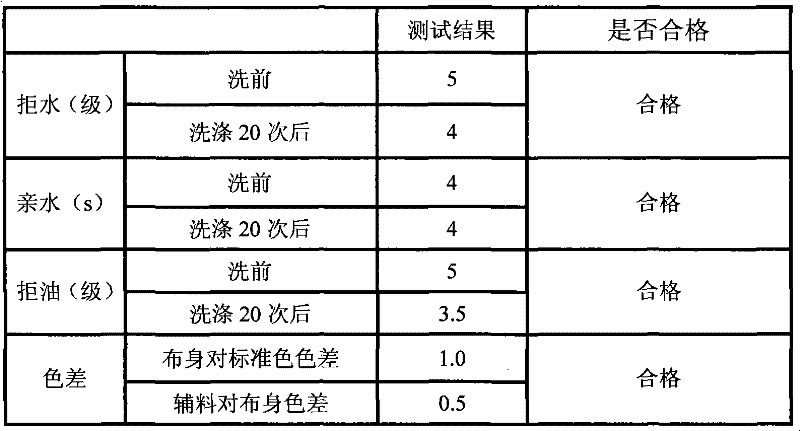

[0015] Example 1: 20S / 1 pure cotton piqué knitted fabric is processed into water-repellent and breathable knitted fabric, and the specific processing process is as follows:

[0016] (1), washing the pure cotton piqué knitted fabric to be treated at room temperature for 8 minutes, and dehydrating;

[0017] (2), add 30g / L of hydrophilic finishing agent RPU into the water, and add acetic acid to adjust the pH value of the solution to 5.0, then soak the cloth in the solution and control the weight bath ratio of the cloth to the solution to be 1:10, Treat at a temperature of 50°C for 10 minutes;

[0018] (3), dehydrating and drying the cloth base after the hydrophilic treatment;

[0019] (4) Add water and oil repellent finishing agent TG-521B 80g / L, crosslinking agent TF-569B 25g / L, softener SI 20g / L, thickener DM-5221 15g / L, and stir well Form a water-repellent finishing solution, then evenly apply the water-repellent finishing solution to the front of the cloth, and bake at a h...

Embodiment 2

[0027] Embodiment 2: 48S / 1 low-twisted compact spun pure cotton double-sided knitted fabric is processed into water-repellent and breathable knitted fabric, and the specific processing process is as follows:

[0028] (1), the low-twisted compact spun pure cotton double-sided knitted fabric to be treated was washed at room temperature for 10 minutes, and dehydrated;

[0029] (2), add hydrophilic finishing agent RPU 20g / L into water, and add acetic acid to adjust the pH value of the solution to 5.0, then soak the cloth in the solution and control the weight-bath ratio of the cloth to the solution to be 1:10. Treat at a temperature of 50°C for 12 minutes;

[0030] (3), dehydrating and drying the cloth base after the hydrophilic treatment;

[0031] (4) Add water and oil repellent finishing agent TG-521B 60g / L, crosslinking agent TF-569B 15g / L, softener SI 25g / L, thickener DM-5221 10g / L, and stir well Form a water-repellent finishing solution, then evenly apply the water-repellen...

Embodiment 3

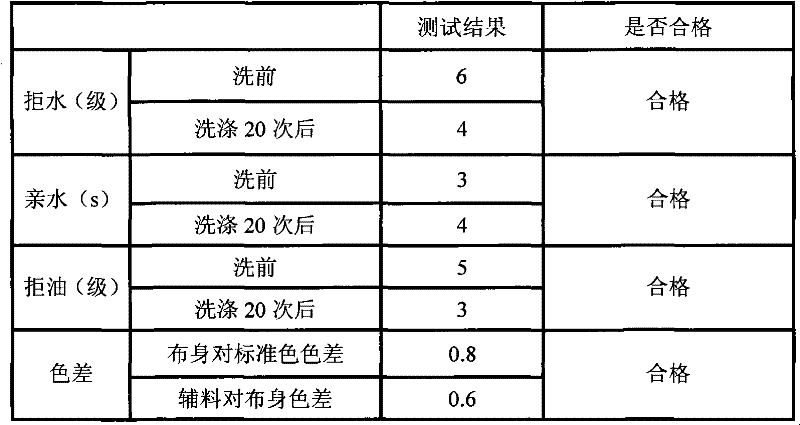

[0037] Embodiment 3: 40S / 1 pure cotton jersey knitted fabric is processed into water-repellent and breathable knitted fabric, and the specific processing process is as follows:

[0038] (1), wash the pure cotton jersey fabric to be treated at room temperature for 5 minutes, and dehydrate;

[0039] (2), add hydrophilic finishing agent RPU 20g / L into water, and add acetic acid to adjust the pH value of the solution to 6.0, then soak the cloth in the solution and control the weight-bath ratio of the cloth to the solution to be 1:20. Treat at 40°C for 8 minutes;

[0040] (3), dehydrating and drying the cloth base after the hydrophilic treatment;

[0041] (4) Add water and oil repellent finishing agent TG-521B 90g / L, crosslinking agent TF-569B 30g / L, softener SI 30g / L, thickener DM-5221 20g / L, and stir well Form a water-repellent finishing solution, then evenly apply the water-repellent finishing solution to the front of the cloth, and bake at a high temperature of 155°C for 50s;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com