Narrow multi-angle boring tower device

A multi-angle, drill stand technology, applied in the direction of supporting devices, drilling equipment, earthwork drilling and production, etc., can solve the problems of poor adaptability, large size, complex structure, etc., to reduce the time for adjusting the drilling rig and reduce the number of auxiliary workers , Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

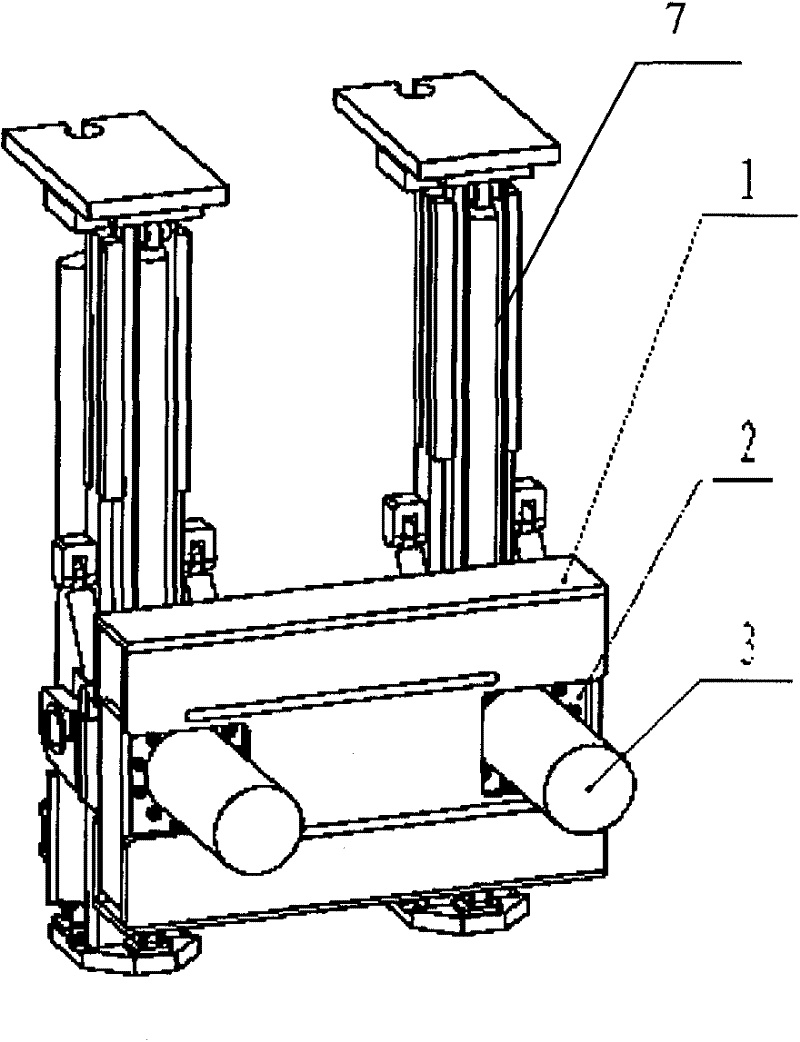

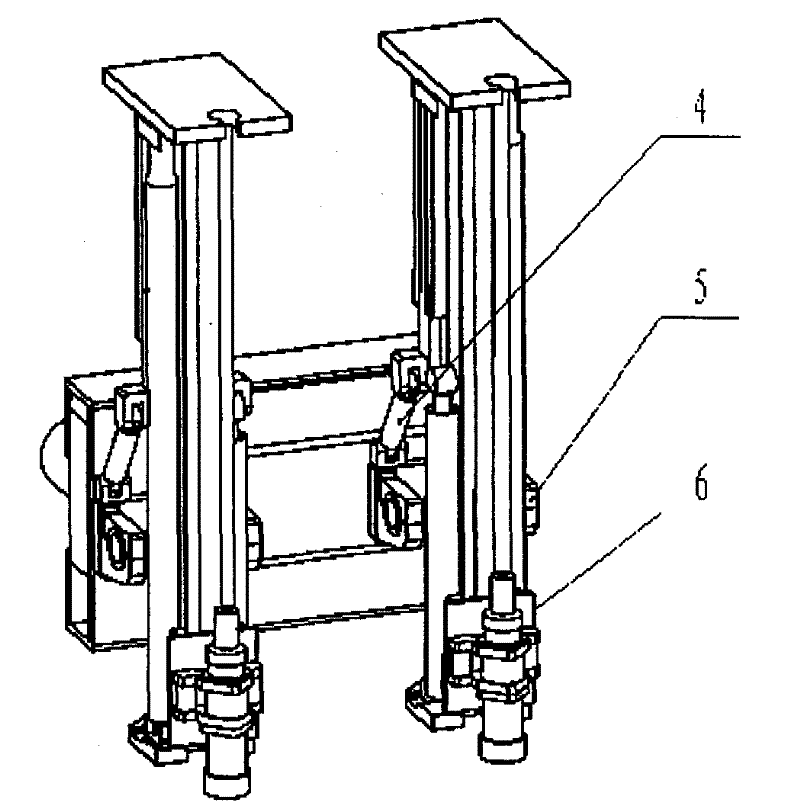

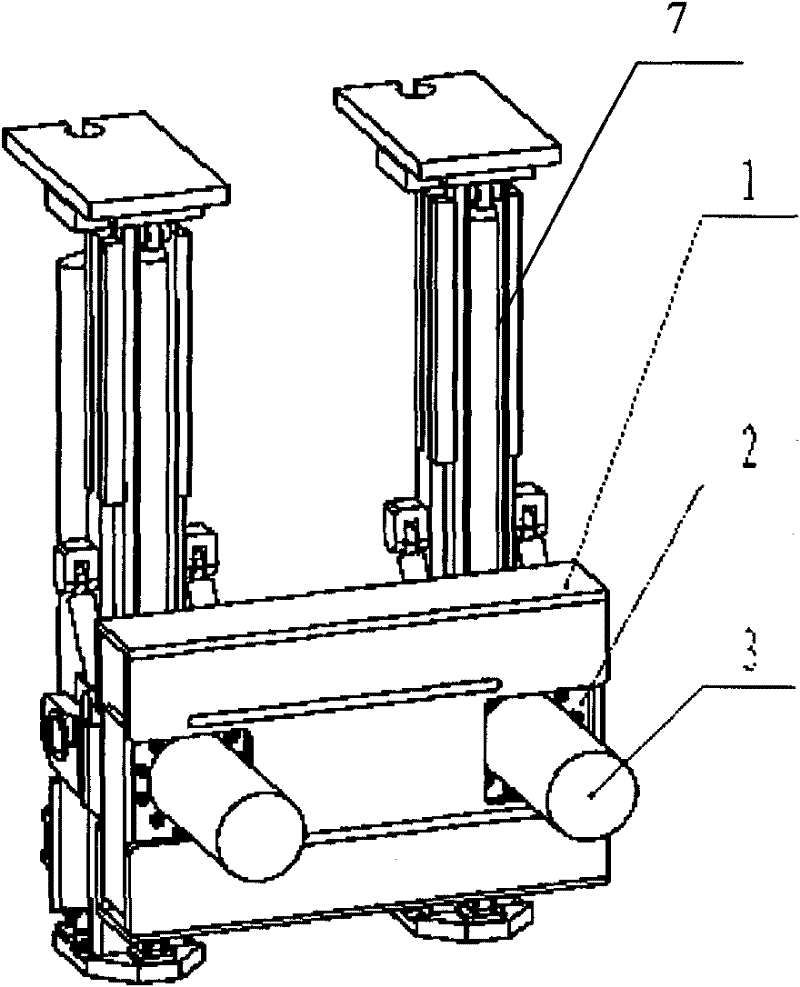

[0012] see figure 1 , 2 The present invention comprises box body 1, arm extension mechanism 2, rotary oil cylinder 3, pitch oil cylinder 4, installation frame 5 and drilling frame 6, and extension arm mechanism 2 comprises telescopic oil cylinder and installation arm 7, and the telescopic oil cylinder built in extension arm mechanism 2 is connected with the The box body 1 is connected, one end of the rotary cylinder 3 is connected with the mounting arm 7 of the boom mechanism 2 through bolts, the other end is connected with the mounting frame 5 through bolts, and the drilling frame 6 is connected with the mounting frame 5 through pins or bolts, and the two Pitch cylinder 4 is set between.

[0013] The maximum appearance width of the present invention is only 1100-1900mm, and the telescopic oil cylinder built in the boom mechanism 2 can real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com