Windmill with relative shift between vane and rotation axis

A technology of rotating shafts and blades, applied in the field of windmill blades, can solve the problems of increasing complexity and cost, and achieve the effect of simple structure, simple production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

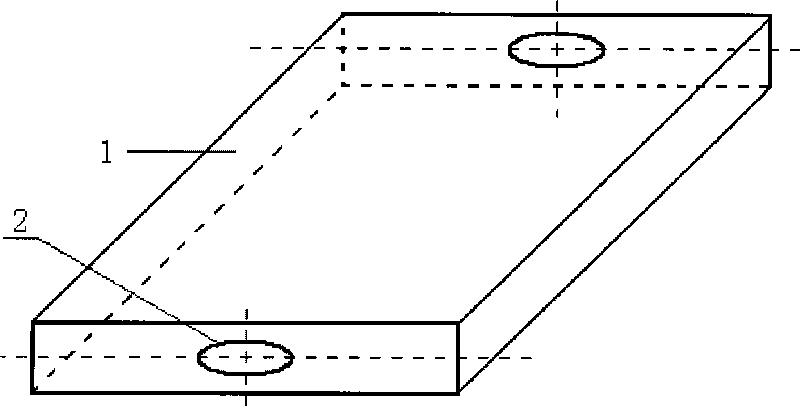

[0018] figure 1 Shown is a blade of the invention with an elliptical autorotation displacement hole. In the figure, proper selection of the long and short axis of the ellipse will directly affect the operation of the blades and even the performance of the entire windmill. Appropriately increasing the length of the minor axis of the ellipse can make the operation of the blade softer, and if the long and minor axes of the ellipse are the same, it becomes a circle. In order to prevent the axial movement between the blade and the blade rotation axis, the method of slotting on the circumference of the ellipse can be adopted, but a cam must be added at the position corresponding to the blade rotation axis and the groove.

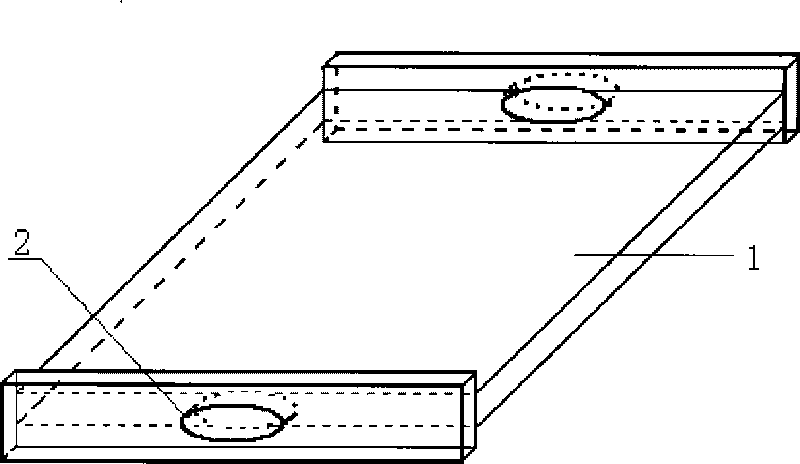

[0019] figure 2 It is a flat blade with an elliptical rotation and displacement hole of the present invention. The flat blade is advantageous when the wind blade is in an upwind state.

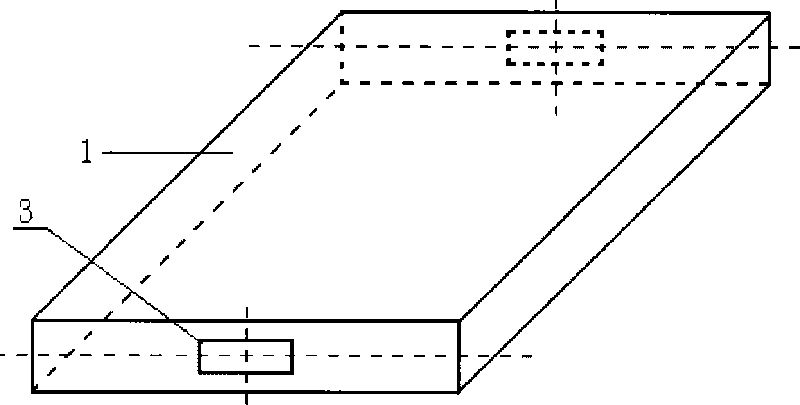

[0020] image 3 It is the blade of the present invention with a rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com