Heat-insulating plate and manufacturing method thereof

A heat insulation board and heat insulation layer technology, which is applied to chemical instruments and methods, heat insulation protection pipelines, heat exchange equipment, etc., can solve problems such as poor heat insulation effect and thick heat insulation boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

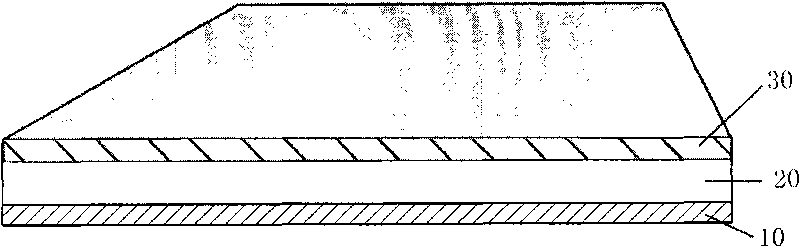

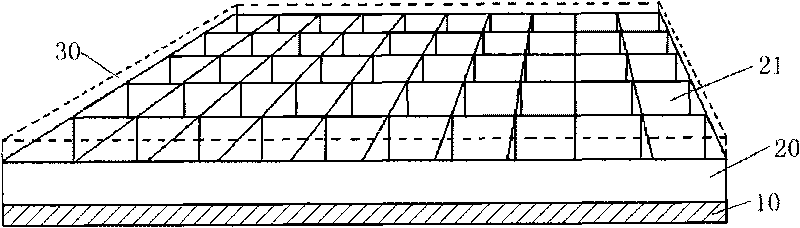

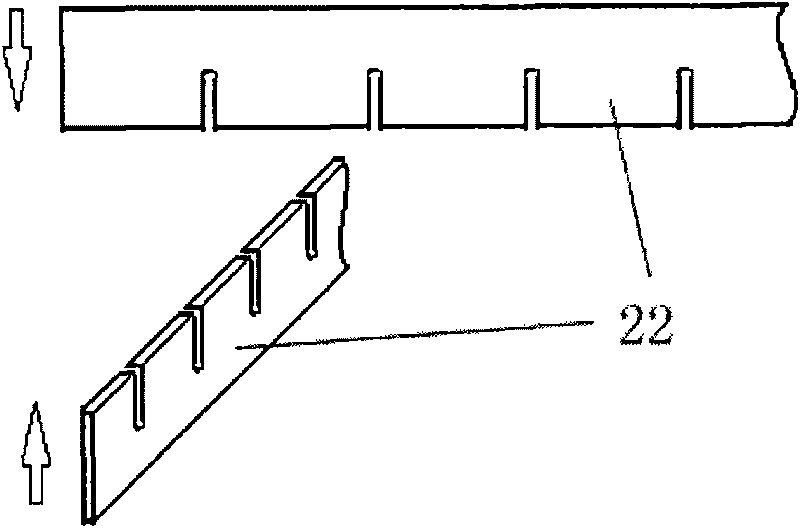

[0011] A thermal insulation panel according to the invention comprises a plurality of metal layers, such as figure 1 and figure 2 The shown thermal insulation panel of an embodiment of the invention comprises two metal layers, specifically, the thermal insulation panel comprises a first metal layer 10, a thermal insulation layer 20 and a second metal layer 30, the thermal insulation layer 20 having A plurality of hollow heat insulation units 21 , the heat insulation layer 20 is disposed between the first metal layer 10 and the second metal layer 30 .

[0012] The first metal layer 10 and the second metal layer 30 can be made of steel plate, copper plate, aluminum plate, titanium plate or alloy plate, the first metal layer 10 and the second metal layer 30 can be made of a kind of metal plate, also can be Different metal plates. According to different heat insulation requirements, the first metal layer 10 and the second metal layer 30 can choose metal plates with a thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com